RE: Horrible quality on a round object with overhang on all sides

See this is why we usually ask people to post zipped up project files. With a project we can see the settings you are using as well as the models/objects and any modifiers etc.

If you are already using 3+ then the solid infill wont be there already so that is one suggestion that is now superfluous given the extra information.

RE: Horrible quality on a round object with overhang on all sides

No you attached a stl and a gcode file. A project file is a .3mf file. In Prusa Slicer you use File>Save Project or Save Project as. That outputs everything in one package. When someone opens it in PS then they get everything identically to what you are using. So for example if you have a particular printer or profile selected then the settings are all in there. If you had painted supports or a variable layer height you get that too. Model placement on the bed etc etc etc.

Its basically the best way to debug issues. While you can import some settings from the gcode file it misses so much compared to a proper PS project.

I'm sorry if my previous response came over as in a huff, that was not my intent.

RE: Horrible quality on a round object with overhang on all sides

No worries at all, I am very thankful for your help. If only we could resolve this issue... I mean, the model doesn't look particularly hard to print, does it? 🙂

Here is the 3mf-file:

It is however VERY basic. 0.2mm quality profile for Prusament PETG, 4 perimeters.

RE: Horrible quality on a round object with overhang on all sides

This just a personal thing and I guess everyone will pile on but I would never try to print with a wall thickness 1mm at any sort of an angle.

RE: Horrible quality on a round object with overhang on all sides

I will now retry printing it slower (75%)... other ideas?

RE: Horrible quality on a round object with overhang on all sides

just saw that now. I will increase wall thickness and try again. Thank god I built this as a parametrized model in F360 🙂

RE: Horrible quality on a round object with overhang on all sides

didn't change much. Same problems.

RE:

Did you fix your issue yet?

I had similar issues, albeit on my MINI+, and the cause was seemingly a partial clog. Performing cold pulls (including some without the hotend PTFE in place), re-compressing the hotend PTFE tube and readjusting my PINDA (a necessary step in many cases after re-compressing) fixed the ugly surface that appeared on the model I was trying to print. Took me a while to figure this one out.

It always started at approximately the same height, I assume because the partial clog worsened after a while at approximately the same spot. I also assumed it must be mechanical, but everything was in perfect working order (good belt tension, no obstructions and smooth axis movement, etc.). Occurred with multiple PLA filaments.

I'm not sure how much of what I did applies to the MK3s but that may be a starting point and in any case it wouldn't hurt to clean your printer thoroughly 🙂

RE: Horrible quality on a round object with overhang on all sides

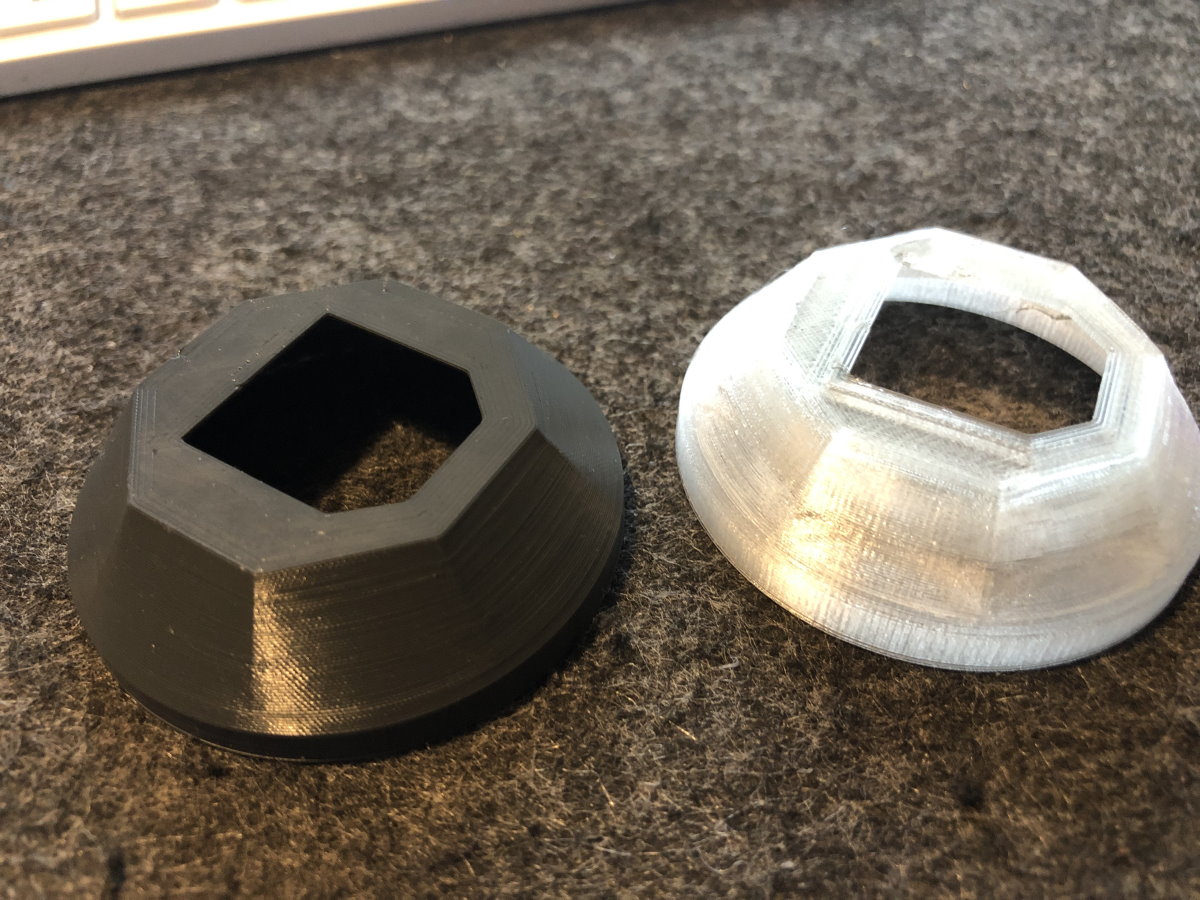

Slople I finally finished the printing I has queued up on my mk3 so I had opportunity to print your part.

General notes about my setup. My mk3 is a slightly modified original MK3 (non s). It is using a parts fan duct that is based on the current S version though. I also have a hardened steel nozzle (Nozzle X) fitted. This means I have to bump my filament print temps up 5 degrees or so in general to account for the nozzle material. I normally print functional prints so I usually print at the top of any temp range for a material for strength. With properly calibrated filament the stringing is minimal (spider web thin which a lighter takes care of in seconds).

As I already had PLA loaded from the previous job (a grey from 3DTommorrow, I normally print it at 235 - yes thats for PLA as the print temperature range is 205-235 according to the manufacturers technical data sheet). I sliced it for that and printed. The result was quite acceptable I think. Oh my normal profile has seams oriented to the rear.

I then changed filament to a petg. I hadnt used this petg before, it was a sample sent to me about 2 years ago from Spectrum filaments (a polish company I bought a fair few spools from). Its labelled up by them as 'Glassy' and has a temp range of 230-255. Thought I might as well use it as its been sitting there so long. I was a bit concerned that it may have taken on moisture as while it was sealed in a bag, it did not have desiccant in there as its only a sample.

I printed that one at 260 degrees c. There was some minor stringing, slightly more than the pla but again the lighter cleared it away in about a second. You expect a bit more from petg anyway but it really was minimal.

I saw none of the issues you were having though. With either material. The profile I used for the filament was a slightly modified Prusament petg one as a base. I have attached a zipped up copy of the project I used for you to examine should you wish.

Hopefully you can make out enough surface details with the clear petg filament.

RE:

@neophyl

sorry it took me so long to get back to you. Thank you SO much for your patience, your profound answers and of course for even printing it! Really helpful.

I took a look at your file and I don't notice any real difference from what I did. I will however anyway now print your "version" with my new spool of PETG Prusament and report.

In the meantime, I spent the rest of the former spool printing one of my serial products, which is way more complicated than this one, and it printed flawless. However, this design seems to have challenges I do not yet understand 😀

RE: Horrible quality on a round object with overhang on all sides

Hey @Slople

sorry to dig up this dead thread but did you ever find a solution? I'm encountering this exact problem printing, with PETG, a model I've made where it starts as a 30mm round object with a straight wall, and then eventually transitions to a 50mm object with a gradual radius and slope. The angle is ~34 degrees on the steepest part, whole model prints flawlessly, except the overhang. My filament is dry, I've messed around a bit with parts fan cooling settings, extruder temp settings, and print speeds, layer heights and I just can't seem to figure it out. I've printed atleast 8kg of this same filament, with no issues.

Did you ever get to the bottom of this issue for your printer? If so I'd really appreciate an update, thanks!

RE: Horrible quality on a round object with overhang on all sides

If I look at the transparent PETG print on the reference machine where it works, it looks to me that the higher layers are considerably more transparent than the lower ones. The change is exactly where the problems seem to start on the Mk4. This looks like a clear indication that due to geometry and layer times each layer gets cooled less overall and therefore stays warmer when the next layer is started. Maybe the Mk4 needs different thermal calibration, ie increased part cooling or lower hotend temperature. Alternatively one could try increasing minimum time per layer. A very easy way to test if me hypothesis is correct is to simply print multiple copies of the part at once, (maybe 4 or so) and see if that changes anything on the Mk4.

Mk3s MMU2s, Voron 0.1, Voron 2.4