Gap in seam while batch printing in first part that starts printing only.

Hello everyone.

The problem:

I am printing a batch of shells/enclosures on prusa mini+. I have one part that just fills the whole bed with copies of it. And the first part that the g code starts with has a noticeable gap in seam area. And all others are perfectly fine with no problems what so ever.

before I have done some other part batch printing with similar parametres ( 0.8 nozle for 0.8 thick walls of a shell/enclosure) and had no such problems.

Any ideas why?

What settings and what software i use.

I use prusa slicer 2.4 with all the default settings for prusa mini+ with 0.8 nozzle. I have detect thin walls ON ( do not remember if it was on or of by default)

I print on prusa mini+ with 0.8 nozzle and it is all stock no modifications or tweaks that running the 4.3.4 firmware.

I print with PLA ( Qoltec Pro PLA )

What have I tried to do to solve the problem

I regenerated the gcode on prusa slicer. - Did not help problem still is there.

I regenerated the gcode on super slicer. Did not help problem still is there.

I have tried changing "extra extrusion on reset" in "filament overrides" from 0.5- 1 . Did not help problem still is there with no changes.

If any one can give some advice I will appreciate it a lot so I dont have to throw out the one part every time i finish printing a batch of them.

Does the gap show in the slicer preview?

Cheerio,

RE: Gap in seam while batch printing in first part that starts printing only.

No, gap does not show up in slicer preview.

RE: Gap in seam while batch printing in first part that starts printing only.

I had/have this with my mk3 when printing multiple cylinders that only have a single wall. Print one of them on its own and its fine. Print several and one of them has the gap in the seam (I have my seams at the rear). Makes the tube unusable.

I even created a redmine for it https://github.com/prusa3d/PrusaSlicer/issues/2485 back in 2019. On mine there appeared to be no un-retract on that part. On the rest of the parts you can clearly see the dot indicating unretract but not on that instance. Seems that it still hasn't been fixed since v2.0

As I never found a fix or workaround I eventually just added an extra sacrificial part.

RE: Gap in seam while batch printing in first part that starts printing only.

I've run into similar issues with 0.8mm nozzles. Can't claim to have figured it out, though. I "solved" it by simply mirroring the object along the x-axis and it printed fine, so I never dug deeper. Maybe some of the slicer gurus and filament whisperers here have some deeper insights. Would love to hear their insights, as I'm sure it's going to bite me again some day.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

You might try moving just that part by a couple of millimetres.

Cheerio,

RE:

@neophyl I have no such problems with exact same parts and batch printing on Prusa MK3S. Only mini has it.

@diem Will try out your suggestion and few others I have been suggested along with some testing on smaller scale batch printing as well. Will keep you updated on how it goes.

RE: Gap in seam while batch printing in first part that starts printing only.

First things first - problem went away. print is still not finished but it is about 50% done and all parts look good and have no gaps in them.

The solution in my case.

I deleted the prusa slicer and did a clean install of the latest available stable version 2.4 ( I had it before so it was a reinstall )

as soon as I did so I rolled back to settings I had that are all stock for prusa mini 0.8mm nozzle and 0.4 layer hight. Except 2 parameters: "extra extrusion on reset" in "filament overrides" set to 0.5 and "detect thin walls" are set on.

I noticed that after slicing that g code no longer started printing from "some middle part" ( the one that ended up defected in previous times) but it starts from left upepr corner and goes down to next one under it and continues so in a wave like pattern. (down a column and themmoves right and goes up a column) This way of printing , at least for me is what I would expect from a printing pattern prevoisu start in the middle confused me with the logics of it.

As a result all just works ! So probably the g code was the fault and clean reinstall of a problem has changed something, like slicers 2.4 generation of code actually took place installed of an old one when I just updated the programm... No clue. But I definitely will be printing more of the same shells still need about 9k of those =) Soo I will have plenty opportunities to play around with settings and hopefully find out what caused the problem and if I find reason and solution will give the information.

Thank you everyone Will keep this post alive with updates.

RE: Gap in seam while batch printing in first part that starts printing only.

Just wondering... The order in which parts are printed is determined by the order of them in the right hand panel. So when you did a reset of the software, I wonder if you re-added the part and/or rearranged the parts. Of course, none of that really explains the gap.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Gap in seam while batch printing in first part that starts printing only.

Just wondering... The order in which parts are printed is determined by the order of them in the right hand panel. So when you did a reset of the software, I wonder if you re-added the part and/or rearranged the parts. Of course, none of that really explains the gap.

Well I re added the part to software as I do always with File->import and the arrangement was done the same way I do always for batch printing - right click part ->fill bed with instances.

And about the print order being determined by the order in right hand menu. I put the top part in the right hand list in the centre of the bed and sliced to test what you wrote ( I never noticed it before and newer knew that was a thing because of that) the gcode still starts from the corner and continues in the pattern I described.

RE: Gap in seam while batch printing in first part that starts printing only.

Oh well, sounded like a good theory to me but clearly didn't survive contact with reality.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Gap in seam while batch printing in first part that starts printing only.

Hi,

I have a similar issue. It is very weird various gridfinity boxes show the seam artifacts. When printing a single object it seems to be better. When printing multiple objects on a build plate most show huge problems with the seems. I tend to also believe it maybe a general slicing / slicer problem?

I am wondering why with exactly the same model (!) duplicated a number of times on the build plate in Prusa Sliver .. some copies do not have an issue with the seam some copies do have. In a regularity that indicates and issue with the slicer actually! Otherwise the seam issue would be random across all models on the same print / build plate.

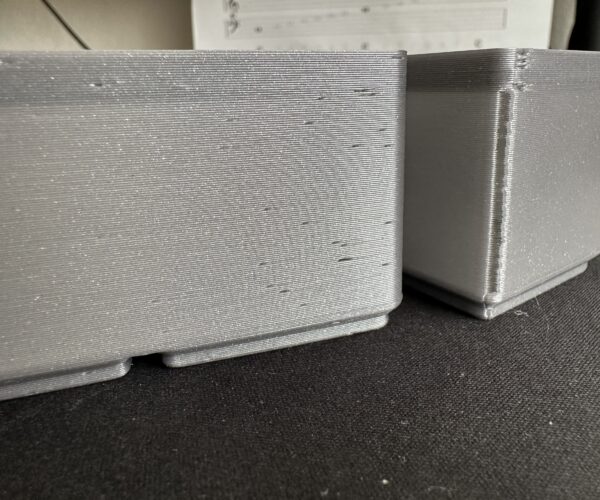

Prusa Slicer 2.5.2 / 0.6 Nozzle / 0.3mm QUALITY Profile Setting (Prusament PLA, Galaxy Silver) / 215°C + 60°C / 0.8mm wall thickness of boxes:

Trying to print with seam random (left) and aligned (right):

I deleted Prusa Slicer now completely and installed the newest 2.6 alpha 6 built. Running some more tests now …

RE: Gap in seam while batch printing in first part that starts printing only.

Hello,

Did you manage to solve this issue?

I am running into the same problem and pulling my hair out.

RE: Gap in seam while batch printing in first part that starts printing only.

Unfortunately not ... even with prusa support we never really found a solution so far. Currently I switched to a Bambulab X1C there it is fine...

RE: Gap in seam while batch printing in first part that starts printing only.

There is a known problem with seams that got worse with the addition of input shaper. There has been a lot of discussion. Search for threads with seams or seam in them. I tried the latest Prusa Slicer 2.7.2 Beta 1 and the problem is still there. There are many issues open on github about this also.

https://github.com/prusa3d/PrusaSlicer/issues?q=is%3Aissue+is%3Aopen+seam

The X1C is a completely different and much more expensive class of printer, and not a Bowden, so it does not share the issues resulting from a Bowden hot end. It appears though that the direct drive MK4 shares this issue, so that points to the slicer. People have reported better results with other slicers. It's a shame, because the prints are pretty good for a cheap printer otherwise.

Regards,

Mark

RE:

Hi,

I am having this issue on both my MK3S and MK3S+, using PrusaSlicer 2.7.1.

I also have a P1S and I use OrcaSlicer to prepare and monitor my prints on that one.

Today I decided to give a go to the default Prusa MK3S profile from OrcaSlicer. I adjusted all the speed settings to match what I have in PS and the seam issue is gone for me. Only downside is prints now take roughly 20% longer than if it was prepared with PS, perhaps because of acceleration settings that I did not touch. Retraction, seam position, speed, layer height, etc. everything is the same.

I might try to reslice my models with a 100% clean install of PS (ditching the inherited profiles from 2.5 and 2.6, as I read in another thread that could be a root cause).

I'll report around here next month.

Note: My MK3S are stock, 0.4mm nozzle. I print with 3 shells, 0.24 layer height, default speed is 160mm/s.

RE:

The X1C is a completely different and much more expensive class of printer, and not a Bowden, so it does not share the issues resulting from a Bowden hot end. It appears though that the direct drive MK4 shares this issue, so that points to the slicer. People have reported better results with other slicers. It's a shame, because the prints are pretty good for a cheap printer otherwise.

Not quite sure what kind of point you are trying to make here especially with completely false information? If memory serves me well ... my MK3S+ was also direct drive - not Bowden. Also price-wise they pretty much play in the same league considering the X1C is basically a P1P with prettier exterior and touchscreen. In this case it is actually vastly cheaper then the Prusa MK3S+ assembled ...

Not trying to start a manufacturer war here but at least get your facts straight. My point was that basically with the same .3mf print file (cause both use prusa slicer) the issue is not existent on my bambulab. That's all ...