Print quality issues

Hello! I posted this in the first prints section, but i think it is better suited here. At least i hope that someone can weigh in with some suggestions. I am presently experimenting with printing the calibration cube at lower temperatures and have noticed that printing at 220°C or even 215°C (using PETG) noticeably reduces the waves in the cubes, but printing at that low of a temp with PETG seems risky.

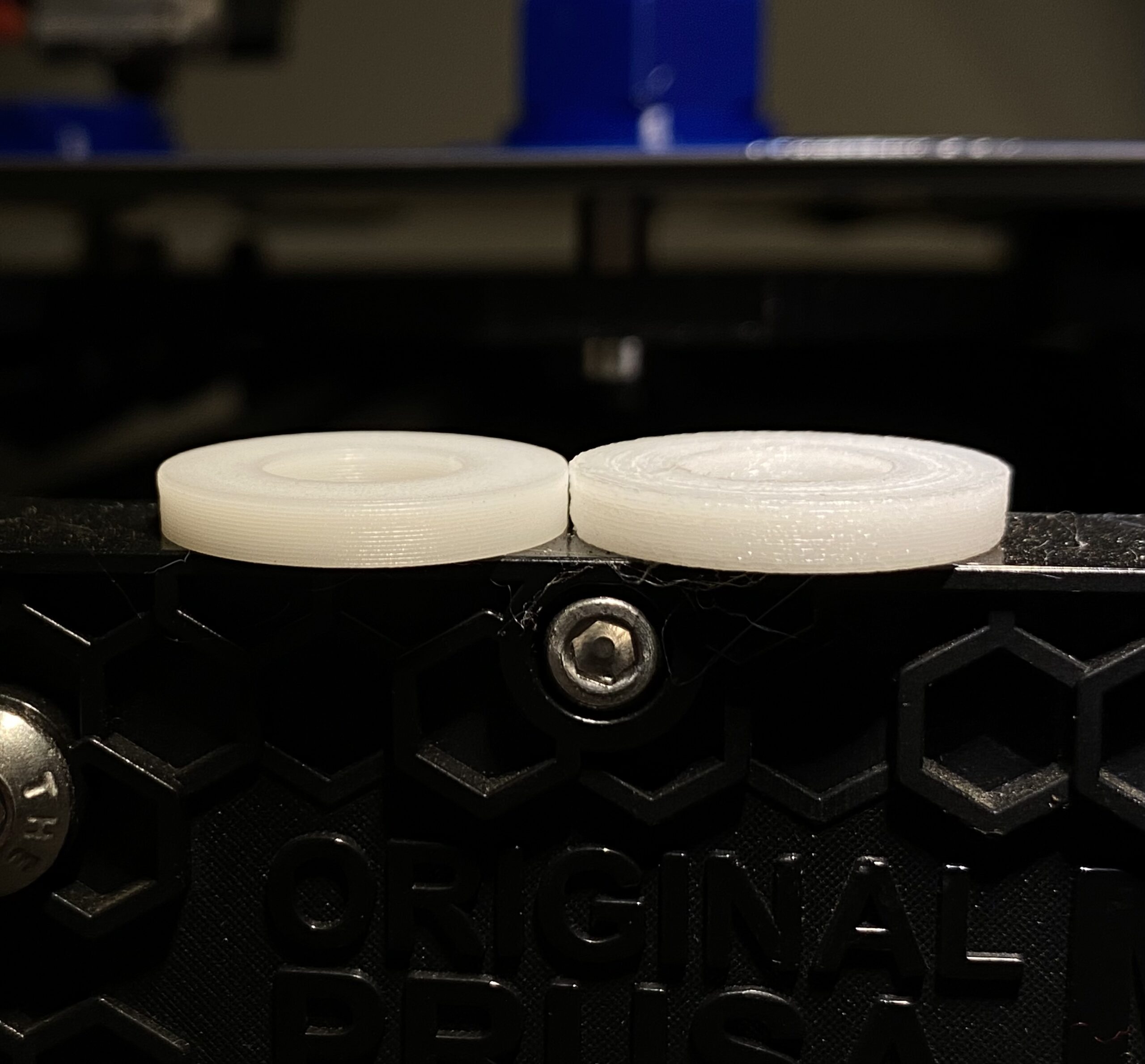

I am having issues with the walls on my prints having very slight waves in them. Attached are 2 pictures and a video of the XYZ calibration cube printed at 0.20mm layer height using standard profiles for PETG for the Mini+. The cube on the left is printed with my older Mini+ running the latest firmware, the cube on the right is printed with my new Mini+ (also on latest firmware). The only physical difference is that I replaced the nozzle and hotend PTFE tube on my old printer with an E3D V6 0.4. Both prints were done back-to-back using the exact same spool so any issues that could occur from moisture in the filament should be eliminated (along with filament inconsistency or quality).

Any suggestions on what I can do to improve the quality of my new printer so it matches my old one?

This is the only noticeable difference between prints across both printers. I believe that this is what is causing more visible waves that appear on another model of mine that seem to correspond to the areas of retraction on that model (once again it prints fine on my older printer). In that part, the waves are worse if the filament has absorbed moisture and even appear with my older printer, but once the filament is dry, my old printer prints the part flawlessly, and my new printer still has issues.

Here is a link to a video showing the issue on the calibration cubes:

https://forum.prusa3d.com/wp-content/uploads/2023/02/20230205_100325.mp4

Is it only the 'X' side that shows this issue?

Check your belt tensions, make sure the smooth rods are clean and lubricated, have you tried printing at a lower speed?

How old is this printer? New machines take a few weeks to run-in after the delivery shake up or the build.

If this is one sided I would also check cooling; is the print fan aligned correctly or is the printer in a draft?

Cheerio,

RE: Print quality issues

I have verified that the belt tensions are all in the correct range. I have checked that all axis are properly squared as well. This is happening on both X and Y axis. This is a new printer (semi-assembled) that has a little over 2 days of print time on it. I have also been cleaning the rods from extra grease.

Initially I was having extra noise and vibration that seemed to clear up after repeatedly cleaning off excess grease from the rods and the outside of the bearings. My guess is that the factory over lubricated the printer.

RE: Print quality issues

Slowing the printer down does not seem to improve the prints and if i slow it down to 30% the surface quality looks terrible (on both my old and new printers). When I print at 220°C, I don't seem to notice the issues. The only "mod" that I have done on my new printer is to add a hotend silicone sock from E3D. Now on my old printer, I did replace the nozzle with a genuine E3D V6 nozzle, but I wouldn't think that would affect things quite so much since the stock nozzle should be of good quality. I am beginning to think that the thermistor on my new printer might be out of spec and reading low resulting in a hotter than indicated nozzle temp. While I have an IR thermometer, I can't really get a good reading from the nozzle (tried a few times).

RE: Print quality issues

Any other ideas or ways to check the thermistor? Or could this just be par for the course to run-in the printer (seems a little odd to take this long though)?

FYI, WordPress has been giving me an error most of the time when I try to post a reply. My replies seem to go through if they are shorter (hence why my reply is broken up across 3 replies).

could this just be par for the course to run-in the printer (seems a little odd to take this long

https://www.kiplingsociety.co.uk/tale/the-ship-that-found-herself.htm

I usually say run-in for a month and then calibrate carefully; it's not worth sweating the small errors now as it will all have to be re done after the machine shakes down.

If you didn't have another printer to compare it with you might not even notice at first, go look at some of your oldest prints .. do they have the quality you've now become used to?

My guess is that the factory over lubricated the printer.

You may be right - but it might be a deliberate ploy knowing that many new users are not used to regular machine maintenance and that it may be some time before the printer gets proper attention.

Cheerio,

RE: Print quality issues

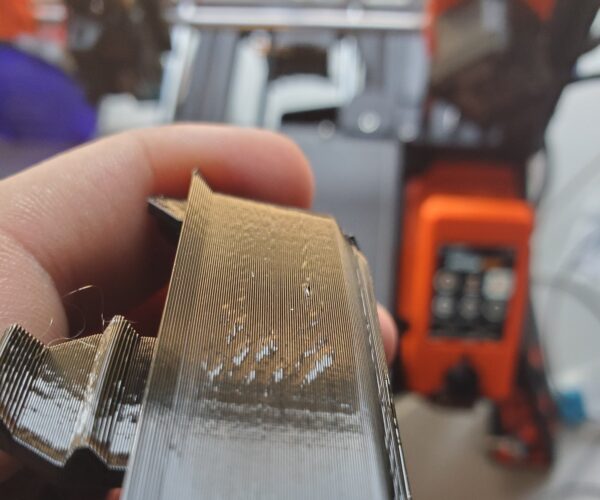

This is my biggest issue with the print quality. Perhaps it isn't connected as I just printed this and the sidewalls look much better (printed it at 220°C), but this issue is still very present. This defect occurs at a place in the model where there is retraction. The exact same file prints perfectly on my old printer. I could live with the small waves that I am seeing in my calibration cubes, but this is a product that I am selling and I cannot sell it looking like this and since the purpose of the printer is for business, that makes the printer kind of an expensive paperweight until I can solve this issue.

Are you sure that filment is dry?

Use the printer as a development machine for a while, or sell some prints a little cheaper as 'Factory Seconds' until your first monthly maintenance session when either it will have shaken down or you will know there is a fundamental problem ...

Cheerio,

RE:

Good suggestions. I am fairly certain the filament is dry. I have a dryer (from PrintDry) and have been putting the filament in it every so often for several hours and keeping the spools in PrintDry's vacuum containers when they aren't actively loaded on the printers. But I have noticed that if the filament isn't dry, the same issues will show up on my old printer - only much less pronounced.

Also upon closer inspection of my gcode, I noticed that the most recent file (the one with lower hotend temps), didn't have any retraction or detractions where the very noticeable surface imperfections are located. There is retraction on the inside face of this wall and it is located approximately opposite the defects, but not on the exterior surface. The wall thickness is approximately 1.5mm and I am using 3 perimeters, which results in the walls being solid perimeters with no infill.

RE: Print quality issues

So a strange thing happened. I rotated my model 90° and then resliced it in PrusaSlicer and it printed without any issues! Now to figure out what about THAT orientation resulted in the print defects... I have an engineering mind and don't like "work-arounds" - I try to know the route cause so that can be corrected.

RE: Print quality issues

Hold on that rotation solving my issues.... I just realized that I was printing it at 220°C and rotated. That did solve my issues, but there were some other things that seem to be problematic as a result. Will be trying a few more prints to see how things go. Will report back.

If rotating the print moves the defect then check the print fan and shroud.

Cheerio,

RE: Print quality issues

The problem is your newer mini nozzle. You can replace it with the original e3d v6 (FYI all prusa mini use generic nozzle, it doesn't have three dots on hex body like original 0.4mm e3d v6 nozzle). I can confirmed about print quality too because i'm having experience same like you. And the only mini that can print TPU 85A with smooth perimeter only printer with a nozzle that i already replaced with genuine one. I already try it with same gcode same filament even print at the same time (i cut filament sample from same spool and print together) and the results is very different. You can zoom in and see the differences between mini with genuine e3d v6 nozzle and mini with default nozzle.

RE: Print quality issues

The problem is your newer mini nozzle. You can replace it with the original e3d v6 (FYI all prusa mini use generic nozzle, it doesn't have three dots on hex body like original 0.4mm e3d v6 nozzle). I can confirmed about print quality too because i'm having experience same like you. And the only mini that can print TPU 85A with smooth perimeter only printer with a nozzle that i already replaced with genuine one. I already try it with same gcode same filament even print at the same time (i cut filament sample from same spool and print together) and the results is very different. You can zoom in and see the differences between mini with genuine e3d v6 nozzle and mini with default nozzle.

Wow! I have been wondering this very same thing. I have another genuine E3D V6 0.4 nozzle that I can install. Should I also plan on replacing the hotend PTFE tube or leave that in since there shouldn't really be any wear or heat damage to it?

This is the only real difference between the 2 printers at this point (aside from my old printer being mounted to the Minibase). I have noticed that reducing the nozzle temp also improves the factory prints, but I haven't found a happy medium yet. Basically, lowering the temp causes some other issues while resolving others.

Rotating the print 90° did resolve the larger defects that were present, but then I experienced another small area of defect (basically on the opposite wall of the part from before, but a different defect)

RE: Print quality issues

I think you don't need to replace the PTFE tube for now, i suggest you to upgrading/replacing hardware one by one. So if something goes wrong, you know what to fix. If you doing all at once you will not know from where to start fixing the issue.