From Ultimaker 2+ to Prusa Mini

Hi everyone,

I'm in need of advice.

Last December I was was given an Ultimaker 2+ connect that I started using a bit. Then I created a very specific mount that I started to sell on Etsy and sales are booming! Hence why I'm here : I need another printer to be able to keep up.

I starting looking at the mini because 1/I don't need a large print bed as I'm only printing small parts petg that are quite flat. 2/I live in a relatively small apartment and can't accommodate anything large. 3/it's cheap.

Now I tend to do a lot of research before buying something and I see a few cons with it the mini.

My main problem is that I'm good at maintenance when I'm given a list of things to do, but I suck at tinkering. I'm worried that I'll be completely lost when it comes comes to replacing an hot end for example. Prusa seems to be a brand for people who like to mod their printer, and that wouldn't be me.

I would also like to have my new printer enclosed, and was wondering if it's something that can be done with the mini. I'm better at DIY building than tinkering with electrical components.

What is your experience with the the mini? Do you think it will fit my needs? How does it compare to the ultimaker 2 I have? I learned the Ultimaker 2 on my own and found it quite easy actually, but it comes ready to print out of the box which was convenient.

Getting a new printer is daunting! I don't even know most technical terms haha

Thank you

Elsa

RE: From Ultimaker 2+ to Prusa Mini

For enclosing, it might not be the best option. There is the belt modification that sounds like it might help you with your production. The belt mod is official, but it was covered on one of the Prusa vBlog.

RE: From Ultimaker 2+ to Prusa Mini

The MINI is perfect up to the task if you are printing PETG, I do it all the time with mine. And for changing parts (like replacing an original part) fear not, Prusas knowledge base combined with their very detailed assembly instructions are second to none. I run a couple MK3S for production of polycarbonate parts and I haven´t done any modifications to the printers, they just work.

RE:

Trust me, there's no tinkering with Mini. The most important thing is, that you assemble it properly and then.. just print -that is, after you make successful first layer calibration.

My advice related to PETG (and I talk from experience) would be... get Bondtech heatbreak. And if it's too expensive (and you can wait a a bit longer), get a clone by TriangleLab (is the same thing). And that's the only thing you should change to be happy camper in long term. Ok, some might say they print PETG just fine with original stock heatbreak.. I say, Bondtech heatbreak is worth every cent!

And if you decide for Mini+, don't forget to purchase textured print sheet (smooth PEI sheet that comes with Mini doesn't work well for PETG). Many also recommend satin print sheet for PETG (which I have, but didn't used it yet).

[Mini+] [MK3S+BEAR]

RE: From Ultimaker 2+ to Prusa Mini

The smooth sheet works fine with PETG if you use a combination of glue stick and Windex on the bed. More glue stick = less adhesion. More Windex = more adhesion. Works great for me. I use the glue stick that turns purple when wet so you can judge the mixture by color on a Kimwipe I use to spread it around. My Mini is bone stock as it came. I have had to rebuild the hot end once after a year and a half of printing, often 16 hours a day. It is picky about what filament you use. It does not like many brands besides Prusament. I buy two at a time for optimal shipping cost. I have it in an enclosure built from an Ikea Lack table, like many others have done. There are many threads in the forums about that.

Regards,

Mark

RE: From Ultimaker 2+ to Prusa Mini

Oh so it wouldn't work well with Polymaker?

RE: From Ultimaker 2+ to Prusa Mini

Well I'm already looking at the extra leg kit that allows you to store the spool underneath hahah! Another user here suggested that the Prusa mini doesn't like any other filament that is not Prusament. Does anyone use any other petg brand?

I'm located in Canada and cannot order Prusament online every time I need new spools. I usually go to my local store and buy Polymaker Polymax which I really like.

Trust me, there's no tinkering with Mini. The most important thing is, that you assemble it properly and then.. just print -that is, after you make successful first layer calibration.

My advice related to PETG (and I talk from experience) would be... get Bondtech heatbreak. And if it's too expensive (and you can wait a a bit longer), get a clone by TriangleLab (is the same thing). And that's the only thing you should change to be happy camper in long term. Ok, some might say they print PETG just fine with original stock heatbreak.. I say, Bondtech heatbreak is worth every cent!

And if you decide for Mini+, don't forget to purchase textured print sheet (smooth PEI sheet that comes with Mini doesn't work well for PETG). Many also recommend satin print sheet for PETG (which I have, but didn't used it yet).

RE: From Ultimaker 2+ to Prusa Mini

I printed up an entire spare set of Mini parts using Hatchbox PETG on a textured bed. All stock on the Mini and it ran just fine. I guess eventually something would wear, but for my project there were zero issues. The parts look as good as, if not slightly cleaner than, the stock parts on the printer.

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE: From Ultimaker 2+ to Prusa Mini

Oh so it wouldn't work well with Polymaker?

I've never tried Polymaker. I had a bad time with a recent Overture spool.

I printed up an entire spare set of Mini parts using Hatchbox PETG on a textured bed. All stock on the Mini and it ran just fine. I guess eventually something would wear, but for my project there were zero issues. The parts look as good as, if not slightly cleaner than, the stock parts on the printer.

I'd look for these type of posts where people have had success and try those brands.

I've used Prusament and Azurefilm with good success. Overture and Sunlu not so much. It's just pickier than many other printers. You just have to try, but if you have problems, try another brand.

It works better with tight tolerance filament and drying makes a huge difference.

Regards,

Mark

RE:

Alright gents! So I pulled the trigger and bought the mini with all the add-ons. Quick question: I'm figuring out an enclosure for that printer, and was wondering what would be the minimum measurements for the mini (when working). Spool and PSU would be sitting outside the box. I have a piece of furniture I can modify that is 23 5/8 " (60 cm, width) by 16 1/2 " (42 cm, depth) by 25 1/4 " (64 cm, height). Would that work?

Thank you

Elsa

RE: From Ultimaker 2+ to Prusa Mini

Oh so it wouldn't work well with Polymaker?

I haven't had any issues printing with Polymaker Polylite PLA on my Mini.

However, the Mini is really picky about filament and works best with filaments with better than ±0.05mm precision. Polymaker makes several product lines of filament. So if it works with one, it doesn't mean it is going to work with all of them.

A big plus is that Polymaker offers lots of colors.

I have had mixed results using Polymaker Polylite PLA with the MMU2 and Palette 3. It seems to vary by color. Some work and some don't.

Here is a good review/thread to check out: Review: Polymaker PolyLite PLA

RE: From Ultimaker 2+ to Prusa Mini

I would only use PETG with my mini. Polymaker polymax petg. Fingers crossed it will work!

Oh so it wouldn't work well with Polymaker?

I haven't had any issues printing with Polymaker Polylite PLA on my Mini.

However, the Mini is really picky about filament and works best with filaments with better than ±0.05mm precision. Polymaker makes several product lines of filament. So if it works with one, it doesn't mean it is going to work with all of them.

A big plus is that Polymaker offers lots of colors.

I have had mixed results using Polymaker Polylite PLA with the MMU2 and Palette 3. It seems to vary by color. Some work and some don't.

Here is a good review/thread to check out: Review: Polymaker PolyLite PLA

RE: From Ultimaker 2+ to Prusa Mini

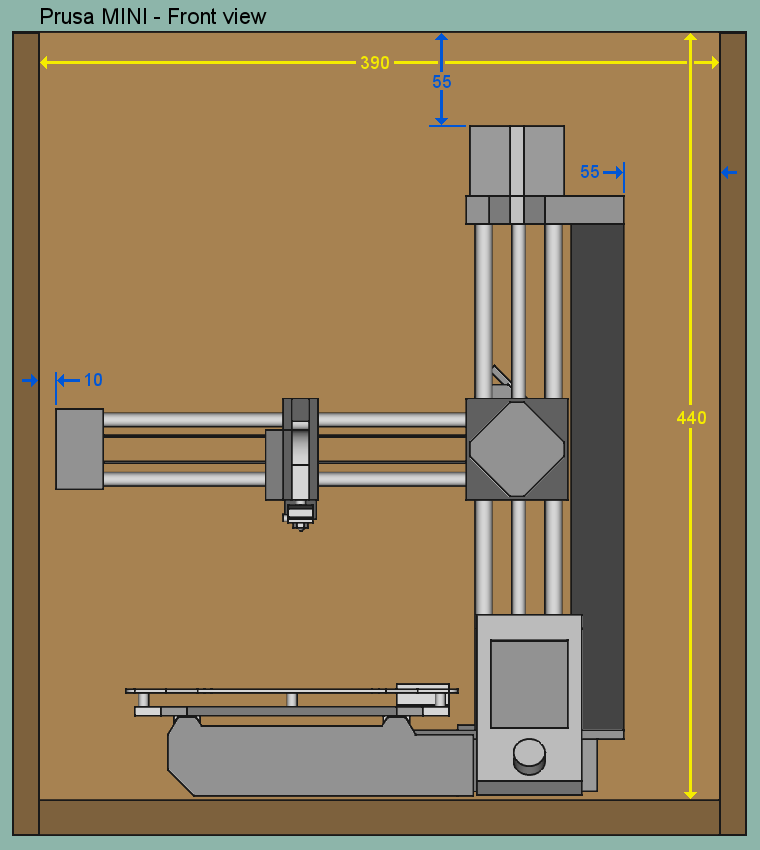

...and was wondering what would be the minimum measurements for the mini (when working). Spool and PSU would be sitting outside the box...

Elsa

-in the right side you need that 55mm free space, so you can be able to load filament into extruder. On top side you need at least 55mm free space, so bowden tube isn't obstructed when print head is on top Z-axis position.

-that would be minimal foot area in case front part of enclosure is open. In case font is closed during printing, then depth should be at least 465mm (410+45+10), so bed can freely move forward. Keep in mind, that connector for bed heating is protruding out (and more so the cable), so you need 125mm distance on the back (between printer base and back wall), to ensure print bed can move fully backward.

I hope that was of some help for you.

[Mini+] [MK3S+BEAR]

RE: From Ultimaker 2+ to Prusa Mini

That's perfect, even better than what I was expecting! Thank you so much! Turns out it won't fit in the piece of furniture I was thinking about, so I'll just end up building my own 🙂 Thanks again!

...and was wondering what would be the minimum measurements for the mini (when working). Spool and PSU would be sitting outside the box...

Elsa

-in the right side you need that 55mm free space, so you can be able to load filament into extruder. On top side you need at least 55mm free space, so bowden tube isn't obstructed when print head is on top Z-axis position.

-that would be minimal foot area in case front part of enclosure is open. In case font is closed during printing, then depth should be at least 465mm (410+45+10), so bed can freely move forward. Keep in mind, that connector for bed heating is protruding out (and more so the cable), so you need 125mm distance on the back (between printer base and back wall), to ensure print bed can move fully backward.

I hope that was of some help for you.

RE: From Ultimaker 2+ to Prusa Mini

The most recent two rolls of Prusament PETG I got had actual tolerance (Prusa measures each roll from beginning to end and gives you a barcode to see the data for that particular roll) of +/- .009 mm. The two leading zeros are not a typo. That is more than 5 times tighter than many other filaments that are +/- .05 mm. The date code was two days before they shipped them to me, so they are very fresh. The two rolls were $76 shipped to the US, or $38 a roll. So, they are not too bad a deal compared to other high end filament. For some reason, third party sellers here in the US jack the price up to $50 a roll or more. Don't buy from them. It may be too late, but I think you can add two rolls to the printer order without increasing the shipping cost. If the Polymaker give you trouble, I'd suggest you order some Prusament to compare.

Regards,

Mark

RE: From Ultimaker 2+ to Prusa Mini

My only concern is that even if I manage to add a few Prusament rolls to my order, I will not be able to get those later on on a regular basis. I live in Canada and shipping them here would cost too much/would take too long. My filament consumption depends completely on how many orders I'm getting each week; sometimes I use up to 4 spools per month, and after receiving my Prusa mini it will probably be even more as I'll be able to fulfill more orders. I don't have that much choice here locally, and Amazon.ca sucks for filament. I'll make Polymaker work! So far it's been great and similar in quality as the original Ultimaker filament.

The most recent two rolls of Prusament PETG I got had actual tolerance (Prusa measures each roll from beginning to end and gives you a barcode to see the data for that particular roll) of +/- .009 mm. The two leading zeros are not a typo. That is more than 5 times tighter than many other filaments that are +/- .05 mm. The date code was two days before they shipped them to me, so they are very fresh. The two rolls were $76 shipped to the US, or $38 a roll. So, they are not too bad a deal compared to other high end filament. For some reason, third party sellers here in the US jack the price up to $50 a roll or more. Don't buy from them. It may be too late, but I think you can add two rolls to the printer order without increasing the shipping cost. If the Polymaker give you trouble, I'd suggest you order some Prusament to compare.

Regards,

Mark