Prusament PETG Orange for PPE

Hi,

I bought this prusament knowing the winding wasn't as perfect as usual and it really isn't...

Already 3 or 4 times the filament jammed on the spool ( 8 hours of printing),

If you consider leaving the printer for hours while printing, paying a few € more for the usual Prusament could be a better choice.

RE: Prusament PETG Orange for PPE

I'm surprised at that. Have you reached out to Prusa via the chat feature on the E-Shop home page?

Have you let go of the end while handling it?

RE: Prusament PETG Orange for PPE

Hi,

Didn't take contact via chat, didn't feel the need because I'm always printing while working, printer next to me.

Think I handled the filament in the right way.

Just wanted to share my experience

RE: Prusament PETG Orange for PPE

That's OK, but it could help Prusa find the problem if you report it, so it doesn't happen again.

Ahh I see now, they do a version just for PPE! It does say on the eShop page that it is not wound as carefully as the regular Prusament and the tolerances are looser than normal, so problems are to be expected. I don't know why they did this, other than to make more of it available in a quicker time.

RE: Prusament PETG Orange for PPE

@geert-hoedt

Yep, I see. They do point it out on the sales page though:

however, to speed up the production, the diameter tolerance is ±0.03mm and the winding is not as perfect as on the usual Prusaments.

I guess the old adage is true... You get what you pay for!

I hope it doesn't cause you too many problems.

RE: Prusament PETG Orange for PPE

I can live with it :), and as you pointed out, I knew before buying...

RE: Prusament PETG Orange for PPE

How dim am I, I didn't think there was any difference between them, just a marketing thing.

RE: Prusament PETG Orange for PPE

I got a spool of the discounted PPE type Prusa orange a while back and it's always printed fine for me on the I3. I have not used it on the MMU2S. At the time, it was said that this was the stuff that was used in their print farm.

RE: Prusament PETG Orange for PPE

It's the same plastic, and it's still made in house but they've loosened the tolerances and not worried about how it's wound, so that it can be produced quicker. I suspect they mean that it's the same type of plastic that they use in their farm, but not the same spooling or tolerance.

The slight difference in thickness tolerance shouldn't be a problem for most people, but the winding could result in tangles on the spool.

Personally I'd spend that bit extra for the better quality Prusament, but it was good of them to try to help people out with a cheaper, more readily available filament.

RE:

This topic may be a bit old (2020). I thought it is still the right place.

I bought last year a Role of PPE petg orange. Now I just started to print with it. I have so bad stringing and kind of "popping" sound (as you would have with wet filament). I can perfectly print with esun petg. One print on the other just fails with this filament. +-0.03 tolerance is still less then the "usual" +- 0.05 cheap filament have. I will contact Prusa Support and see what happens.

I used the standard profile for PrusamentPetG (unless this was the wrong one)

RE: Prusament PETG Orange for PPE

I have so bad stringing and kind of "popping" sound (as you would have with wet filament)

Do you expect the filament to stay dry forever in its package? It IS not dry anymore.

Humidity diffuses through normal plastic bags over time. The small amount of silica or clay inside the bag gets saturated over time and does not absorb the diffusing humidity any more.

Dry the filament and it will print perfectly. 😀

RE: Prusament PETG Orange for PPE

Hi Stefan

"Do you expect the filament to stay dry forever in its package? "

I have PetG and PLA filament that is over 1.5 years old (in its original package) and still works perfectly (eSun, Geeetech). I would expect that 6-12 month after production the filament should be printable (at least for PLA and PetG). I will dry and test it next week

RE: Prusament PETG Orange for PPE

[...] I have PetG and PLA filament that is over 1.5 years old (in its original package) and still works perfectly (eSun, Geeetech). I would expect that 6-12 month after production the filament should be printable (at least for PLA and PetG). I will dry and test it next week

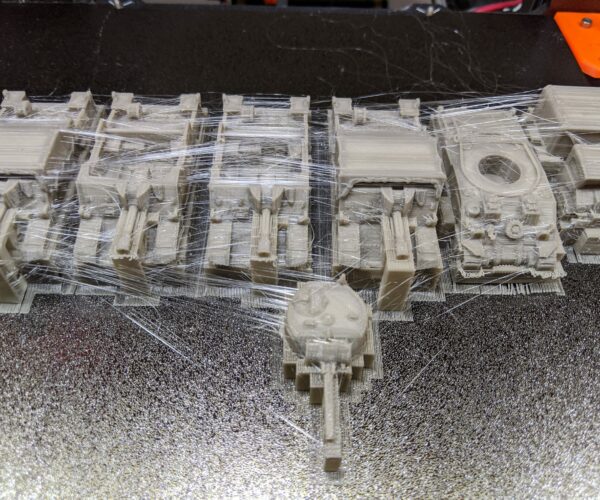

It will vary depending entirely on local conditions. I've printed with Overture PLA extensively. One winter day we had unusual atmospheric conditions and this happened:

After drying, everything was back to normal. In general, if I start to get stringing or other anomalies, before changing my hand-tuned presets, I'll dry the filament or try another spool. Most of the time, that takes care of filament-related issues. PETG is particularly sensitive to moisture absorbtion.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Prusament PETG Orange for PPE

very good information provided by a filament manufacturer:

https://fillamentum.com/pages/drying-filaments-before-processing/

RE: Prusament PETG Orange for PPE

Thank you for the link - very interesting statement from Fillamentum

RE: Prusament PETG Orange for PPE

I dried it for 8 hours, now it prints fine.

RE: Prusament PETG Orange for PPE

The drying temperatures given by Fillamentum on that link mostly agree with the ones in the manual of my Print-dry dryer unit, concerning PLA, PETg, nylon and ABS, but the figures for Flex seem way too high. Print-dry recommends 55C for TPU/TPE, same as PLA, as those fillaments have a similar deflection temperature (55C or whereabouts). There must be an error in the Fillamentum document. 100C for drying Flexfill 98 !. Really ?. That's too high even for PC or Nylons.

If you dry TPU or TPE for several hours at 80-100C it will soften a lot and the threads will stick among themselves until you get an unusable spool.

very good information provided by a filament manufacturer:

https://fillamentum.com/pages/drying-filaments-before-processing/

RE: Prusament PETG Orange for PPE

100C for drying Flexfill 98 !. Really ?

read the data sheet for this material. They say the material can be used at temperatures up to 100 C, so it seems correct for their material

RE: Prusament PETG Orange for PPE

According to Prusa's material table, Fillamentum Flexfill TPU-98 has a deflection temp. of 53ºC. That doesn't means that it will break just above 53C when you stretch it, but I expect that it will become progressively softer and, above 80-90C, it won't retract by itself anymore after being stretched, as it would at room temperature.

Call me skeptical but, in spite of Fillamentum claims. I wouldn't risk heating an expensive spool of TPU up to 100C to check if it stands the torture test or it has become like boiled noodles. 55C should be enough to dry TPU.