2.0mm nozzle on a Prusa

Hello All,

I have a prusa coming on the way. I was wondering if anyone have used a nozzle with as wide as a 2.0mm diameter. From what I understand prusa has a different kind of nozzle then other printers, so I'm not sure if I can mount any nozzle into the prusa.

In the help page the width goes up to 0.8mm https://help.prusa3d.com/article/different-nozzle-types_2193

If anyone can let me know if you have done this or where I can find a 2.0 mm nozzle for prusa please let me know!

Thank you all

Renan

RE: 2.0mm nozzle on a Prusa

Prusa offer profiles for 0.25, 0.4, 0.6 and 0.8 mm nozzles.

Probably best using.0.25 nozzlesi expect 0.2 would work with the 0.25 extrusion values

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: 2.0mm nozzle on a Prusa

Hi Joan, thanks for your reply. I need a 2 mm thick nozzle, not 0.2!

R

RE: 2.0mm nozzle on a Prusa

I do a lot of 0.8 mm printing but haven't gone beyond that. I'd be concerned about the stock hotend's ability to melt and push filament fast enough.

RE: 2.0mm nozzle on a Prusa

I don't think you can extrude 1,75mm filament through a 2,0mm nozzle, even if the hot end would generate enough heat to melt it... You would need a bottleneck in the nozzle to make sure the filament gets contact to the metal to get heated and enough pressure to fill the lower 2,0mm diameter part of the nozzle fast enough to extrude evenly- sounds very unlikely.

If at first you don't succeed, skydiving is not for you.

RE: 2.0mm nozzle on a Prusa

I think it is impossible. I mean, filament is 1,75mm thick, how do you melt and squeeze it through a 2mm hole??

I know about 3mm filament, but that´s not for stock Prusa...

Prusa i3 MK3S+ FW 3.11.0 (kit dec -20), PrusaSlicer 2.5.0+win64, Fusion 360, Windows 10

RE:

The largest nozzle diameter available on the market is 1mm. For example, you could drill a 0.4mm nozzle to 2mm, but you will not get sufficient results with a 1.75mm filament. And even if it works, the heating element will not be able to feed enough material (limited volumetric speed).

( https://nozzleboss.de/?product=v6-nozzle-10mm-messing-175mm-fuer-e3d-e3dv6)

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: 2.0mm nozzle on a Prusa

Thank you Karl, then I imagine the largest I can go would be around 1.5mm, if I drill 0.4mm nozzle. What do you think?

R

RE: 2.0mm nozzle on a Prusa

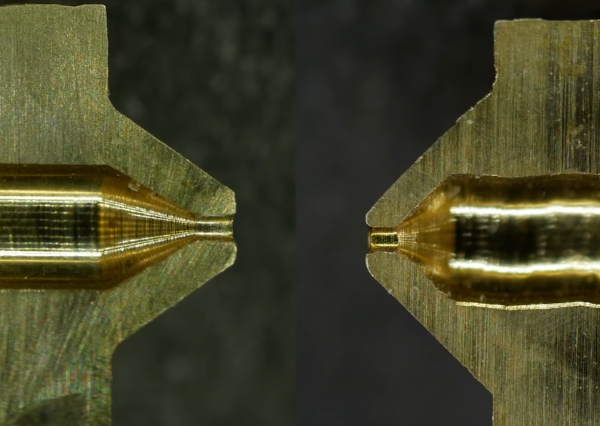

As I always say -> the proof of the pudding is in the eating. The 1.5mm hole should have a smooth surface and burr-free.

(left: good, right: sub-optimal)

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: 2.0mm nozzle on a Prusa

Typically 3D printer that use large nozzles, use 2.85mm filament / hot ends to be able to meet the flow requirements of the larger nozzles.

Just making the nozzle size larger doesn't do any thing to increase the capacity of the hot end so it can support that kind of flow rate.