3Dprinted ball from two halves and screw

I saw nice "Nothing, just another useless machine #Shorts" youtube video from "My Tech Fun" today, on a ball throwing and catching machine.

He 3Dprinted spoons and ball, where he printed two ball halves and a M8 screw to connect. I thought he did that to get a ball without support, but that is not clear. Here is story with STL files and link to youtube video:

https://www.mytechfun.com/video/158

With the help of youtube-dl and ffmpeg I created this (small part of his 59 second video with sound) cropped and scaled to 25% size animated .gif — I like that (the real throw as well as slomos):

In comment to his video I stated what could be next step, replacing Arduino with Raspberry Pi and adding a camera for automatic parameter determination …

RE:

One point I like on "My Tech Fun"s 3Dprinting is that he did print what flies (the ball) as well.

I did similar recently, 3Dprinted my own airgun pellets constructed with freecad, sliced with cura on Ender-5 3Dprinter of younger son (I will definitely do next pellet prints with PrusaSlicer and my new MINI+ soon). Here with 4.4mm diameter, 0.6mm bottom and 1.4mm high, 0.6mm thick cylinder on top:

Why did I 3Dprint my own airgun pellets?

Because the mosquito pellets I had were just too slow (only 80m/s or 110m/s) for supersonic speed shots.

The maximal speed I recorded with gun chronograph was 439.2m/s(!) (or 1581km/h, see bottom right) — sonic speed is only 343m/s:

https://forums.raspberrypi.com/viewtopic.php?t=319956&hilit=chronograph&start=25#p1952927

As can be seen I experimented with "spaceship like" pellets as well, in order to get close to 10mg pellet weight. Will do that more with my MINI+ soon (minimal thickness of cylinder was 0.6mm with Ender-5 printer to get two 3Dprinted circles on each layer).

Why did I want supersonic speed pellets?

In order to capture supersonic speed pellets inflight with multiple exposure photo Raspberry camera!

The photo was created with five 2µs duration 10000lm led flashes, 100µs apart (in completely dark room).

Pellet did fly 0.7mm(!) during 2µs flash exposures, so not really sharp — since recently I can generate 100ns unit duration flashes with Raspberry Pico MCU, with my self built highspeed flashes (38V/3A or 100W per 10000lm led):

https://forums.raspberrypi.com/viewtopic.php?t=319956&hilit=chronograph&start=25#p1956584

RE: 3Dprinted ball from two halves and screw

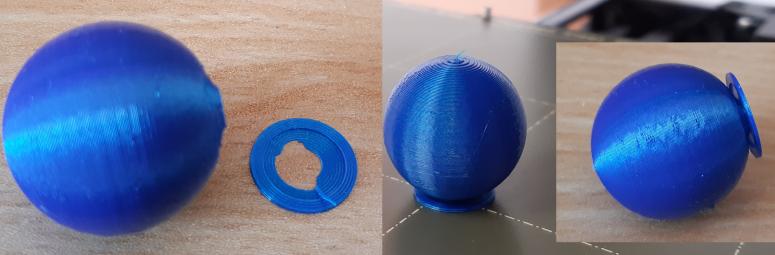

Back to topic, I 3Dprinted sphere from two halves with My Tech Fun's STL files on my Prusa MINI+.

I learned that having screw thread that is not 360° around has the advantabe, that a gripper can be used to screw into 1st half of sphere. That was absolutely needed, otherwise I would not have been able to screw in completely. Screwing 2nd half sphere was easy.

Then I did 3Dprint 23mm diameter sphere just as is without support (with same 15% infill as before, OctoPi nozzle camera view) …

… in order to see how it goes. I did enable brim for fixating the sphere while printing. Even with that the very first layers were wobbling during printing, and I thought I would get a complete fail.

But it worked flawlesssly! After removing brim it is not perfectly a sphere, but sandpaper is likely to fix that:

RE: 3Dprinted ball from two halves and screw

With that ball model you would normally print both sides flat to the bed. So the equator line on both is downward. The bottom of a sphere or any similar geometry is never going to print well as it is in effect an extreme overhang.

RE:

With that ball model you would normally print both sides flat to the bed. So the equator line on both is downward.

Thank you, I did that, only for 1st photo I showed wanted to show inside

RE: 3Dprinted ball from two halves and screw

A ball is very difficult to print, not helped by the 0.2 first layer height set by most default profiles.

RE:

As last exercise for this topic I wanted to 3Dprint sphere with much bigger diameter without support, for more extreme overhang.

My Raspberry Pi400 64bit OS has no PrusaSlicer compiled yet, and the 64bit appimage does not work:

But I was able to install and use 32bit appimages on two Pi4Bs running 32bit Raspberry PiOS.

First I tried maximal diameter 180mm for my Prusa MINI+. And first I tried on my 2GB RAM Pi4B. Slicing 180mm diameter sphere did reboot the Pi 😉

Next I tried on my 8GB Pi4B, no reboot there, but PrusaSlicer was killed trying to slice.

So next I created 100mm diameter sphere with freecad on my 64bit Pi400 (freecad does only work on 64bit, crashes on 32bit PiOS), exported as STL and sliced with brim. Expected print time with 15% infill was more than 13 hours. But I did want to print the start only anyway.

Yes, there were issues, but overall I was surprised that this works at all:

I did capture nozzle camera mjpeg stream with wget, and measured average framerate as 14.3fps in parallel with mjpeg_fps tool. Then I converted captured mjpeg stream to 14.3fps .mp4 and uploaded to youtube. Details on that in this posting:

https://forum.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles/simple-nozzle-camera-borescope-holder-for-prusa-mini/#post-591721

1:03min heating to 170°C completed, bed leveling 2:06min bed leveling ended, further heating started 2:30min heating to 210°C completed, start of print 17:54min print cancled, did not move up fast enough to avoid small ball 18:50min end of video

"Prusa MINI+ 3Dprinting 100mm ⌀ sphere w/ brim w/o support (correct framerate)"

RE: 3Dprinted ball from two halves and screw

As a total printer noob ......wow, impressive

RE: 3Dprinted ball from two halves and screw

Again a ball, contrary to subject printed in one piece, different to before with 0.4mm thick wall and empty inside.

I learned how to print single circle per layer wall in this posting:

https://forum.prusa3d.com/forum/prusaslicer/why-does-prusaslicer-show-one-ring-but-prusa-mini-does-print-two-per-layer/#post-596047

Nozzle camera 9:35min video of 3Dprinting 20mm diameter sphere with 0.4mm thick border:

There were only small issues at very top before finishing print — ball does weigh 555mg only:

I did 3Dprint adapter for cheap suspension ball blowing experiment to fit 20mm diameter of printed ball:

https://www.aliexpress.com/item/1005001483527505.html