Why does PrusaSlicer show one ring, but Prusa MINI+ does print two per layer?

I experimented with 3Dprinting supersonic airgun pellets again.

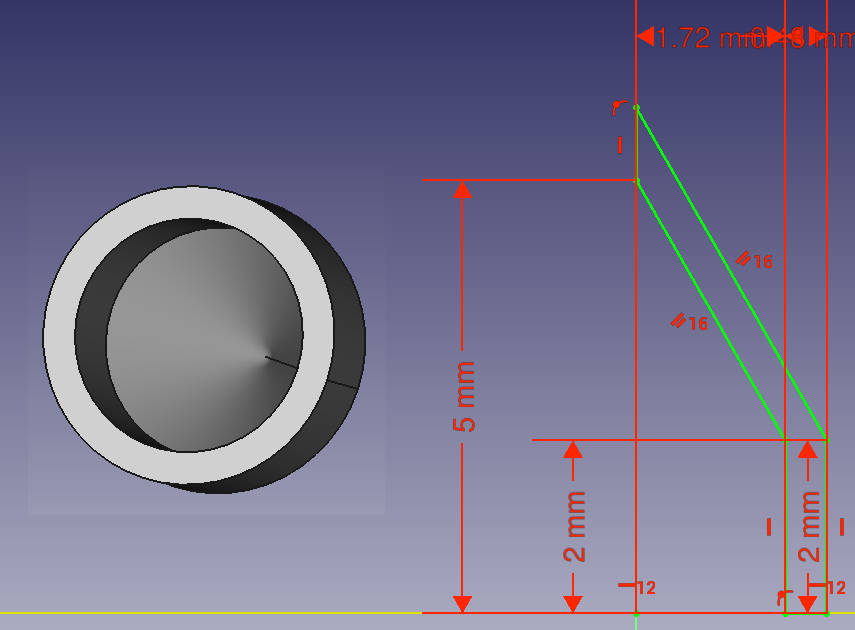

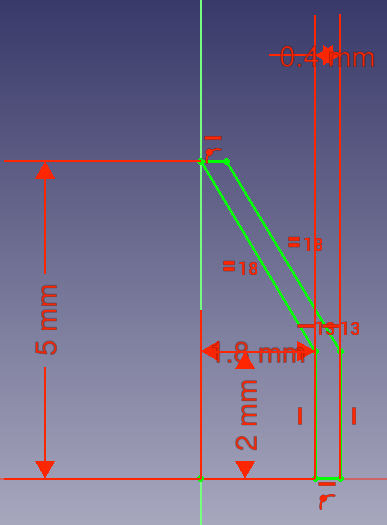

I created a ring with an empty cone on top by doing a 360° revolution around Z axis of the XZ plane sketch shown in FreeCAD:

Border thickness is 0.48mm, inner radius 1.72mm, resulting in 4.4mm outer diameter to fit into 4.5mm caliber airgun. Speed measured by gun chronograph was only slightly supersonic (351m/s), but that is not the problem/question. Also I know that my filament is not dry enough, again not the problem here.

I chose 0.48mm thickness because 0.45mm resulted in a lot of holes created by PrusaSlicer (that I don't want):

PrusaSlicer shows only one line for 0.48mm thickness and 0.4mm nozzle default of Prusa MINI+ (animated .gif captured with "peek" screen recorder):

But the nozzle camera video shows clearly that each layer gets two (overlapping) circles.

1st question is why?

2nd question is, how can I get 1 ring per layer without many holes inserted?

RE: Why does PrusaSlicer show one ring, but Prusa MINI+ does print two per layer?

Regarding 2lines on same height can be it compromise somehow.

Have you check rule small wall ?

RE: Why does PrusaSlicer show one ring, but Prusa MINI+ does print two per layer?

Your ps video is showing 2 overlapping lines. You have to look carefully. I can tell it’s over lapping on the preview. You have to experiment with your extrusion widths in slicer to get it to use a single wall if that’s what you need. It’s counter productive to adjust your model too much until you understand what the slicer does with various settings.

RE:

Thanks to both of you.

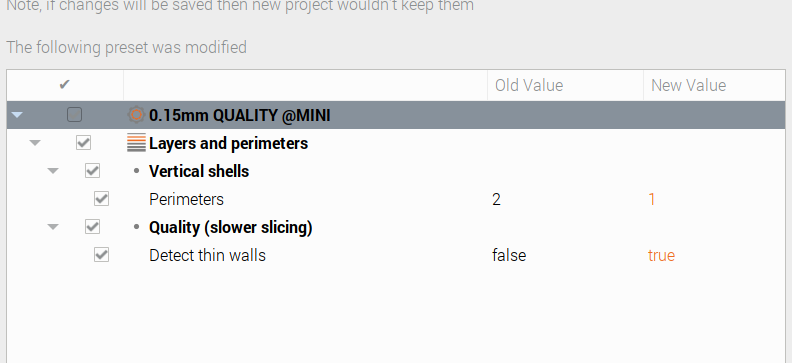

I found the parameters to change, for what I want — both settings are needed:

For those changed settings I created slightly different pellet revolution, with wall thickness exactly 0.4mm and removed top:

3Dprinting was without issues — besides that there should not be a top, more settings to change:

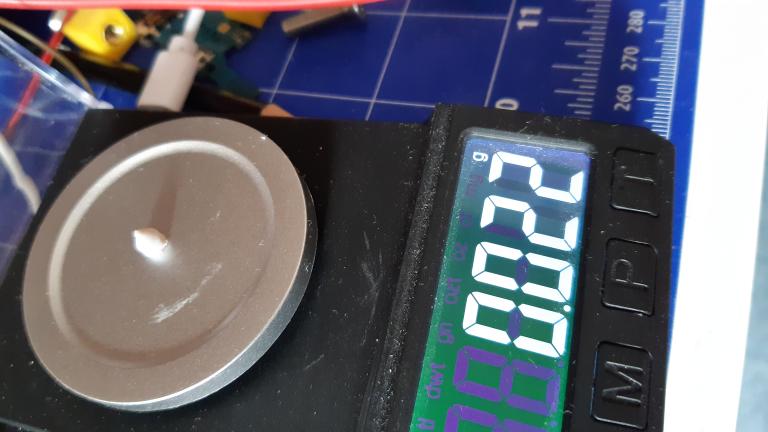

Weight of this pellet was 32mg before, now it is only 22mmg:

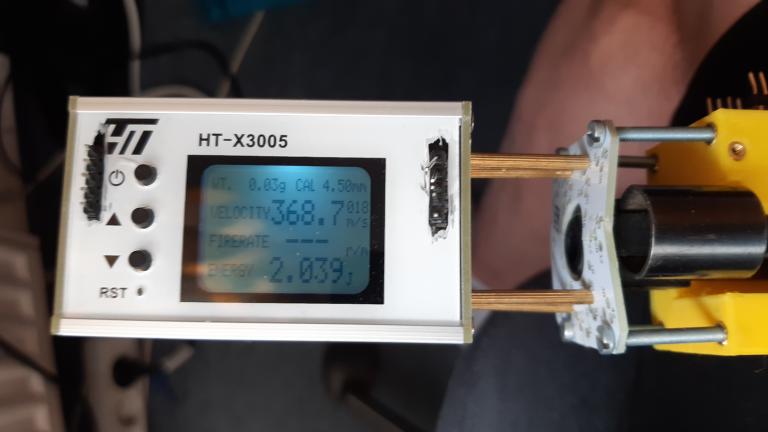

Gun chronograph shows that this pellet is slightly faster than before (Mach 1.075).

Energy is 50% too high, since I forgot to reduce pellet weight (top left) to 0.02g.

(unfortunately photo shows that plate in contact with barrel got broken a bit)

RE:

I tried to print positive cone with negative cone inside resulting in 0.4mm thickness, and 10mm height, with top radius of 0.2mm, and then mirror that on top. The hopping between brim and lower cone in 2nd and 3rd layer made it always break. Then I added 0.4mm thick and 0.5mm high ring below lower cone, and now it mostly worked. Only just after middle height the first "circles" of cone are not perfect. But overall even that got corrected some layers above. Quite light weight double cone of height and diameter roughly 20mm.

RE:

Nozzle camera video shows that there are also some smaller problems in bottom cone. After 3:53min start of top cone the problems I discussed can be clearly seen: