What to do if the filament sticks

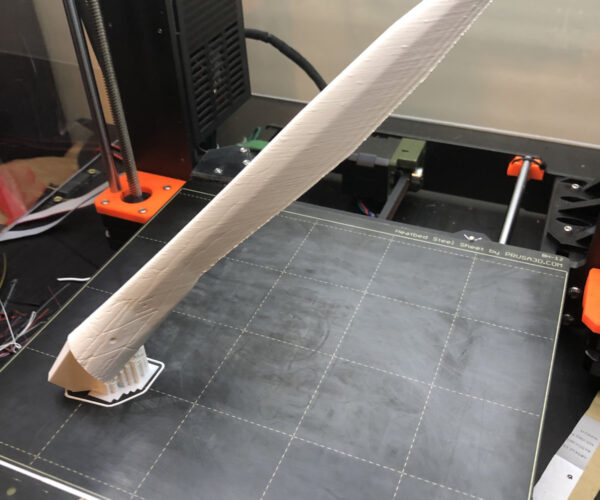

Hello everyone. What should I do if I get into a situation like the one in the picture? I want your opinion. Thank you.

Best Answer by Bob:

So, you've been attacked by the dreaded blob monster. I've encountered this fierce beast twice, once on my Ender 3 and again on my Prusa I3 Mk 2.5s. Both times I had started a print, it was looking good, and I left the printer unattended. Sometime after I left, the print detached from the bed, stuck to the hot end and caused the molten plastic to wrap itself around the hot end.

So, what do you do about this? Well, first, be prepared to buy a new hot end. You can buy one from Prusa3d.com for about $73. Another option may be to buy the E3 Revo Micro. Now, I'm not saying you'll have to, just be prepared because cleaning this thing is going to be a challenge.

I hope for your sake that you were using PLA when you encountered this printing disaster, if you were using PETG that'll make things more difficult as the printed parts on the Mini are PETG and you could damage those part if the blob contacted them. I was printing PLA and it didn't stick to my PETG or ABS printed parts.

To remove this you need to heat the hot end to whatever temperature you were using when the blob monster was created. Once up to temp take a pair of needle nose pliers and carefully pull the blob away from the hot end. If you're lucky you'll pull away a majority of it. As you remove more and more of the blob you'll need other tools like a small screwdriver or a toothpick to get into the crevices clear away as much of the plastic as you can. You definitely want the space between the heater block and the heat sink as clean as possible as any plastic in there will insulate the heat break and lead to jamming. If you're lucky enough to get most of the plastic off, your final step is to take a small wire brush and burnish the heater block on any side that does not have wires. Clean the 3 other sides and the bottom around the nozzle, there are grub screws in the block you may need access to later if your thermister or heater core need to be replaced.

This is delicate work during which, if you're unlucky, you may break a wire. When working on my Ender 3 I broke a wire to the thermister which essentially was the end of the road for that hot end. Without the thermister I could no longer heat the hot end to facilitate removal of the plastic, so I bought a new one and replaced it. My Ender 3 is back in service working as well as ever. On my I3 I was lucky enough that I could remove the blob without doing any damage. Once I had the Ender 3 hot end on my work bench I was able to use my soldering iron to heat the plastic and remove it. In some areas I used a hobby knife to pick away the plastic and completely disassemble the hot end. I replaced the broken thermister and now have the rebuilt hot end in my spare parts box.

Good luck and take care around those wires, if you're lucky you won't do anymore damage and you'll have your printer back in service soon.

Cheers

-Bob

RE: What to do if the filament sticks

So, you've been attacked by the dreaded blob monster. I've encountered this fierce beast twice, once on my Ender 3 and again on my Prusa I3 Mk 2.5s. Both times I had started a print, it was looking good, and I left the printer unattended. Sometime after I left, the print detached from the bed, stuck to the hot end and caused the molten plastic to wrap itself around the hot end.

So, what do you do about this? Well, first, be prepared to buy a new hot end. You can buy one from Prusa3d.com for about $73. Another option may be to buy the E3 Revo Micro. Now, I'm not saying you'll have to, just be prepared because cleaning this thing is going to be a challenge.

I hope for your sake that you were using PLA when you encountered this printing disaster, if you were using PETG that'll make things more difficult as the printed parts on the Mini are PETG and you could damage those part if the blob contacted them. I was printing PLA and it didn't stick to my PETG or ABS printed parts.

To remove this you need to heat the hot end to whatever temperature you were using when the blob monster was created. Once up to temp take a pair of needle nose pliers and carefully pull the blob away from the hot end. If you're lucky you'll pull away a majority of it. As you remove more and more of the blob you'll need other tools like a small screwdriver or a toothpick to get into the crevices clear away as much of the plastic as you can. You definitely want the space between the heater block and the heat sink as clean as possible as any plastic in there will insulate the heat break and lead to jamming. If you're lucky enough to get most of the plastic off, your final step is to take a small wire brush and burnish the heater block on any side that does not have wires. Clean the 3 other sides and the bottom around the nozzle, there are grub screws in the block you may need access to later if your thermister or heater core need to be replaced.

This is delicate work during which, if you're unlucky, you may break a wire. When working on my Ender 3 I broke a wire to the thermister which essentially was the end of the road for that hot end. Without the thermister I could no longer heat the hot end to facilitate removal of the plastic, so I bought a new one and replaced it. My Ender 3 is back in service working as well as ever. On my I3 I was lucky enough that I could remove the blob without doing any damage. Once I had the Ender 3 hot end on my work bench I was able to use my soldering iron to heat the plastic and remove it. In some areas I used a hobby knife to pick away the plastic and completely disassemble the hot end. I replaced the broken thermister and now have the rebuilt hot end in my spare parts box.

Good luck and take care around those wires, if you're lucky you won't do anymore damage and you'll have your printer back in service soon.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: What to do if the filament sticks

Hi Bob.

Thank you for your advice.

I was in despair when I encountered the blob monster, but I should have kept my cool. As it turned out, it was a weak blob monster. I took your advice and heated the hot end and was able to defeat it. As you said, it took some time to overhaul it afterwards. It worked fine now. Thank you very much.

However, I don't think I have solved the fundamental problem.

Like Bob, the first layer is printing beautifully, and if I leave it alone, it is having babies. I have been trying to figure out why this is happening. I thoroughly cleaned the heat bed and made a new heat bed and it worked. Could this be the cause?

I know this is a long story, but please help me.

RE:

If the part is detaching then the first layer is not printing fine. How did you clean the bed ? Bed adhesion is down to 2 things. Cleanliness and Live Z height. Get those 2 things right and you can do amazing things.

First of all cleanliness. Take your print bed to the sink and using plain dish soap detergent (like dawn or fairy) scrub the plate with clean paper towels and lots of HOT water. Rinse with more hot water and dry with more clean paper towels. Then avoid touching the surface of your bed at all as your finger oils will just ruin your newly lovely and clean surface. Handle by the edges. For the smooth sheet you dont need anything more than this. No IPA or anything for normal use.

Over time printing pla can build up a residue which needs a more through and longer scrubbing to remove. Some use the green side of a new dish sponge for that but I have never needed too. I just scrub using paper a bit harder, more elbow grease. But this really only kick sin after months and months of printing.

Next use the jeff jordan method of adjusting the Live Z setting. Not the built in one as it only has limited utility to get you in the ball park. https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

Get those 2 right and you can do stuff like

or

With adhesion sorted you shouldnt have any more blobs as it will stick to the bed rather than the extruder.

RE: What to do if the filament sticks

b-core, I'm glad you were successful, you should mount that blob monster on the wall over your printer to celebrate your achievement.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: What to do if the filament sticks

Neophyl is demonstrating some impressive adhesion. I'm going to offer another choice for cleaning, one that works well for me. I have a spray bottle with 50% distilled water and 50% 91% IPA. I created this mix initially as a home grown hand sanitizer for Covid19, but found that it works well as a cleaning spray. I spray it on my bed and use a micro fiber cloth to wipe off. This has proven to work pretty well for between print cleaning. It doesn't mean you won't need to use other methods, but for a quick cleaning it works well.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit

RE: What to do if the filament sticks

Ms. Neophyl

Thanks for the great advice.

I am a newbie and have not been diligent in cleaning the seats. I will clean them very carefully from now on.

Looking at the aging of your seats, I'm not quite there yet.And your work is awesome! I didn't know what PRUSA was capable of yet.

RE: What to do if the filament sticks

@b-core

Another suggestion for cleaning, similar to Bob's 50/50 Water/IPA Alcohol mix; I use lens wipes (used for cleaning lenses) which are water and IPA alcohol based to clean the bed (after cooling) and every so many prints I also clean the nozzle (while still hot). It keeps the nozzle pretty clean and the bed good. I've had to wash the bed once (in about 3m) to reduce/eliminate warping from some large piece. I also recommend (personal choice) to use a silicone sock to keep the heater block cleaner; that has worked very good and I am now an advocate to the sock because that is how I lost two hot-ends on my previous printer (cause of the stupid blob getting everywhere).

Best luck

RE: What to do if the filament sticks

Like languer I too use a silicon sock on my printer and can attest to it's ability to limit the effect of the blob monster. In my case I put the sock on after upgrading my Mk2 to a Mk2.5s, the new print head resulted in the part cooling to cool my heater block 14 degrees below the set temperature which cause a thermal runaway shutdown. The sock insulates the heater block preventing this, but also gives the blob less to grab onto. Be sure and recalculate your PID settings if you install a sock, it'll change the characteristics of the heating block.

Cheers

-Bob

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit