What exactly is my problem here?

Hello all,

I have my Prusa Mini+ for about a month now, and managed to get a few consistent prints out of it, but nothing really good, at least from seeing what others printed with the Mini.

My setup:

- dasfilament.de PLA 1.75 @ 230°/85° first layer | 230°/60° other layers - Extrusion multiplier 0.95

- 0.4mm stock nozzle

- 0.20mm Quality Setting (only change: 1st layer to "0" / auto because otherwise I got non-sticking 1st layer)

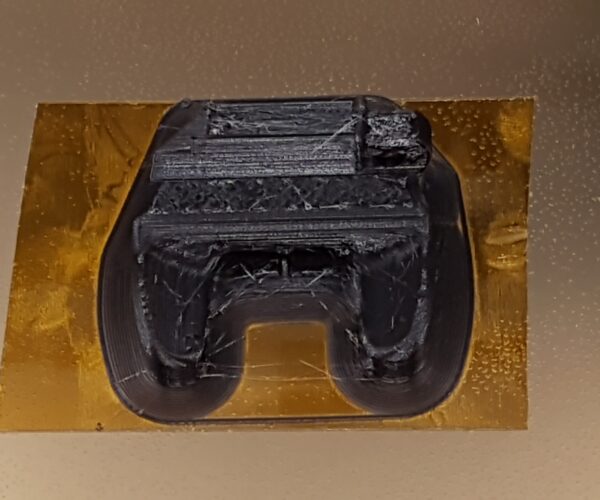

Yesterday I started printing this hextile shape, and am clueless why it looks like this. You look at the bottom (first layer) which is meant to be up in the final print.

I see various issues I cannot seem to get rid of, I will name/decribe them 1 by 1

1. Those broken corners on the first layers:

2. Those underextruded? lines in the last fill layer. The strange thing is: those appear in the exact same pattern on the same spots, but sometime (2 out of 6 exact same printsfrom the same slice) they are not present at all. There is nothing strange in the slicer, I have no idea why they are there.

3. Those 1st layer infill lines not exactly merging with the 1st layer perimeter.

Basically as this will be a playing board, I am aiming for the cleanest/most polished look to the 1st layer (the top of the Hextiles later)

Thanks in advance for looking into this, I hope I have not forgotten any information - if so, I will happily provide it.

Best from Germany

Markus

RE: What exactly is my problem here?

Why are you running so hot? It's the upper limit of the Das Filament PLA and should only really be used if you're running fast for prototyping. Try something like 210 for all layers, maybe 215 for the first layer. Bed heat is also a large difference, you're too hot on the first layer and could be causing it to drag the filament up since it's staying gooey and not cooling enough to harden. PLA can handle no heated bed, but 60C is great for all layers so first and all. Also, just setting to 0 isn't the best, a properly set Z Live is what you need, this ensures a proper squish for adhesion, and the squish fills in the gaps you mentioned as well. Another note, is your extrusion multiplier is at .95, put this back at 1. From the topside images, I can see little gaps between the lines, and it also effects the gaps on the bottom, so your extrusion multiplier is too small.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: What exactly is my problem here?

Thanks for your post @skreelink , I will try to answer the questions one by one (and explain what led me to dialing them in) - and I started a print in parallel with your given solutions.

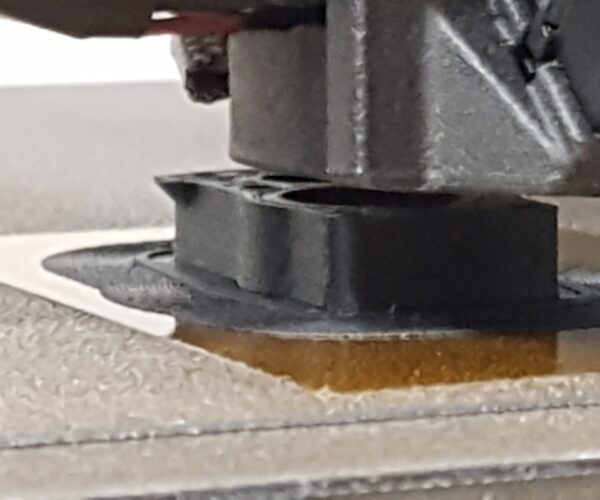

Prerequisite:I guess, I got the Z calibration pretty good, as the Calibration test is satisfying and it looks good on the infill layers (see pictures) I i go lower, it seems to peel off again. But again, I only can guess it looks right - at least like in the manual and online resources.

Why are you running so hot?

Simple as that: I got underextrusion and not sticking 1st layer and eventually extruder clicking /grinding when going below 225° and raising the temp fixed it. That's why I sticked to it as it is still in the 215° +/- 15° rating from the manufacturer.

you're too hot on the first layer

That was countermeasuring the fact that the PLA was not sticking to the bed on lower temperatures, peeling off and sticking to the nozzle/heatblock

Also, just setting to 0 isn't the best

It was marked as "automatic" so I guessed it is not the worst option. I set this back to the 0.42 coming from the stock 0.2 profile.

Another note, is your extrusion multiplier is at .95, put this back at 1.

I figured that one out printing the "testcube" from Prusa - I got overextrusion (from the images shown on the site) and lowered it until it looked like the "reference" image.

Changing everything now back to where I started I got this result:

As i am finishing this post, my testprint mentioned in the beginning also "finished". It peeled off after the 2nd turn. By looking at it, the material hits the bed, then curls back off as it was cooling too fast?

That is the starting point basically, from where I started dialing in the above values to get at least stick to the sheet:

The bed is totally clean, rubbed with IPA 99% after every print.

Thanks for your time, much appreciated.

Best

RE: What exactly is my problem here?

Ok my mind is blown. I never tried PETG filament before and remembered I had ordered one single spool because of the colour from Das Filament. So i loaded it. I changed NO settings (besides switching to the "PETG Prusa" profile ofc) in slicer and changed nothing (Live-Z, Bed, etc) on the printer and am currently printing right away:

How is this possible? Why does the PLA not stick, but the PETG does print well from the get-go?

RE: What exactly is my problem here?

@sawomar

IPA wasn't enough to me.

try cleaning PEI sheet by hot hot water and dish soap, dry without touching the surface.

RE: What exactly is my problem here?

PETG can Over adhere to the build plate, which is why glue stick is recommended for a release agent to prevent sticking too hard...

I used to use IPA for cleaning my build plate and Like you, I got to a stage where the prints would not stick,

Now I simply wash the build plate, with Hot Water and dish detergent. forget the IPA, and I get excellent adhesion... with PLA...

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: What exactly is my problem here?

Thanks @turro75 and @joantabb for the replies.

I had already cleaned the plate with normal "fairy ultra" dish soap and used no IPA after. I read that several times now. I used the "non abrasive" part of the sponge and let it dry on a towel - After that the result was exactly the same to be honest and I switched back to using IPA as Prusa recommend it. Should I use the abrasive (green in the picture) side?

A small note: I used PLA from Geeetech, Sunlu, the Prusament sample and dasfilament. It was all the same. On some point I reread the guide because I was unsure if there was some "protector" on the sheet, because it was behaving so badly. The "Live Z" test always works, but it is straight lines and no curves etc.

The problem now is: PETG sticks as it seems (currently waiting for the print to finish) - PLA does not at all. I got some 20 rolls of PLA and want to use them. If the PLA was behaving like this single roll of PETG i got, I would mark the thread solved right away, but it is not the case.

RE: What exactly is my problem here?

A few good answers here, but why PETG works better? It's stickier! 🙃 Simple as that, do be careful on the smooth PEI sheet as noted above, however. It can stick TOO well and tear the sticker (at least it does have another side, just incase). Luckily, I've never had to go the hot water/dish soap route yet, IPA has always been good enough for me.

Make sure to clean the plate when it's room temperature. If you can, get a small spray bottle, spray the plate a couple times, let it sit for a few seconds, then clean it from the center outwards. However; maybe try another brand of IPA if you can? I've heard reports that some IPAs seem inferior and actually don't work well, likely due to any filler agents (even if 99%). Definitely try not to touch the surface with your fingers, I suggest plastic razors to assist in removing any particularly stuck print, this and pouring a little alcohol can help release a lot of things stuck too hard.

For the PETG, instead of the mess of gluestick, I would suggest using Windex or equivalent glass cleaner. This is suggested on the Prusa FAQ for PETG, and a friend of mine with the MK3S and only smooth PEI uses this method after I suggested and it's worked beautifully for him vs gluestick. It cleans, but also leaves a thin layer of the other fillers just enough that PETG still sticks very well, but has enough release it doesn't hurt the PEI sticker. So after this print, do make sure to put something down just in case.

For PLA, make sure the fan isn't on for the first few layers, just to make sure it isn't cooling and curling. Your Z might be a tad too low and the nozzle itself is pulling up the print. Only speculation, as we're not there to really help. The PETG is looking rather clean, though.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: What exactly is my problem here?

@sawomar

The fun point about Prusa, is that they recommend lots of things at various times, and some people delight in being obnoxious (Just happened on Face book) Claiming that their view of life is the ONLY Valid view....

If you look at the last paragraph, on this page,

https://help.prusa3d.com/en/article/i3-printers-regular-maintenance_2072

you will see that Prusa also recommend soap and water...

I always Dry my Build sheet Immediately after washing.

I have used the green side of the sponge, on occasion some folk use 1000 grit or higher wet and dry paper,

I did use Acetone on an early build plate, and the PEI surface went brittle and cracked. so I don't use that anymore

it's good to know as many options as possible, and choose what is most appropriate to you...

Good luck,

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: What exactly is my problem here?

I'm running a clone so maybe that doesn't fit to your original, anyway:

try to unload / load filament, with the stock extruder I always had to do an additional purge to see filament out at nozzle during load, after replacing the extruder to a bondtech clone, I get filament out almost immediately.

My stock extruder were sliding and not pushing very well the filament, this can cause underextrusion and first layer issues getting worse over time. clean it.

Other reason for first layer issues could be clogged nozzle or ptfe tube damaged/out of position.

moisture in the filament also doesn't help.

Regarding bed cleaning, I use a lot of hot water (You can see the water removing the dirt), some drops of concentrated dish soap and I clean it by hands and nails. I just avoid touching the bed surface while rinsing and I dry it with toilet paper or anything else absolutely clean. Now I use IPA only to degrease bearings and clean rods.

No more first layer issues.

This is valid for both PEI and powder coated sheet.

RE: What exactly is my problem here?

I can only confirm this! Cleaning with fat-dissolving detergent, rinsing with water and then drying with a lint-free cloth is the best and cheapest method to prepare the printing plate for printing. Possibly rewipe with IPA but acetone or similar I would avoid. I always finish a new plate with a 1200 grit wet sandpaper before using it for the first time. I never actually use glue. Kapton, for example, when printing Nylon and PEEK. But I guess everyone has their own recipe.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: What exactly is my problem here?

@karl-herbert

I have used water down Elmers, glue stick, dissolved gluestick, and several others. It is rarely needed but can come through in a pinch when you need it.

--------------------

Chuck H

3D Printer Review Blog

RE: What exactly is my problem here?

I was given this advice and it works well for my mini.

PLA - use smooth sheet and clean occasionally with IPA and paper towel, about 1 in 5 prints

PETG - use textured sheet and clean with window cleaning spray and paper towel

i have a different Live Z for each of PLA and PETG sheets

Adhesion is always good if Z adjustment is good. I used to be cautious about going too low but realise now that so long as my ner can feel a slight bump on the lines of a first level calibration then all is good. Clean again where your finger touched.

All settings are Prusa Slicer defaults for PLA and PETG.

Over the last year I only raised temperature once, and it did give a better print. But this was only as I had a tiny blockage in the hot end which I was unable to see. After much patient effort, I cleared the block and went back to standard slicer setting. Since then my Mini has been super reliable.

RE: What exactly is my problem here?

When I print critical materials such as CarbonPEEK or CarbonNylon, often the best way to increase adhesion is to get the first layer very close to the absolutely clean print bed. Sometimes, however, an adhesion promoter cannot be avoided, and here I have had the best experience with Kapton after numerous tests.

CarbonNylon (3dxtech)

CarbonPEEK (3dxtech)

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: What exactly is my problem here?

A HUGE thank you to everyone in this thread contributing to what I call success!

I "wasted" the last two weeks tweaking settings, adjusting Z, cleaning the bed with everything suggested.

Actually my bed was to smooth obviously, printing with PETG however showed me the settings (Z etc) and Hardware (Extruder / PTFE etc) were fine.

After the suggestions here I gave my bed sheet a slight rubbing with SCOTCH BRITE ultrafine.

My mind was blown: PLA sticks like it should, yields extremely accurate results, as I could also now lower the temp to 210° - as suggested.

Also I have no residue from a partly failed 1st layer dragging on and eventually getting disposed in higher levels.

I was near selling this printer out of frustration. I still cannot believe that this simple 5 strokes with the Scotchbrite can change the whole game so drastically.

Thanks again to all the kind folks in this thread and greets from Germany

Markus

It's like miracle now to me, I am currently printing my 7th piece, look at those results compared to the one I posted yesterday:

RE: What exactly is my problem here?

Could you please post what your first layer calibration print looks like? The one with squigly lines and a little rectangle at the end. If the sheet is degreased well (as many have suggested above), the problem often lies in first layer calibration - and specifically not pressing the filament hard enough against the bed.