RE: Still Lost After Weeks Of Trying

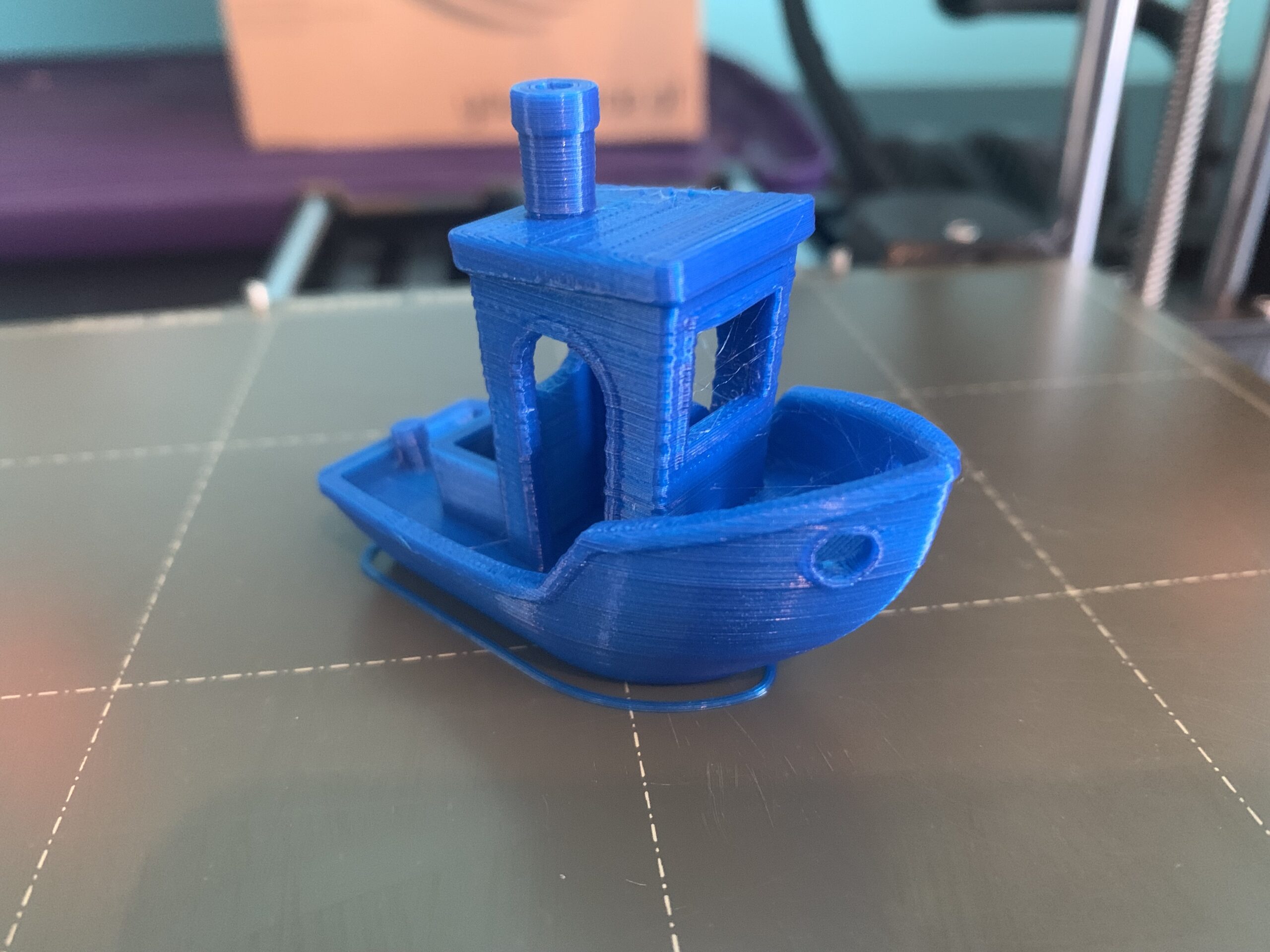

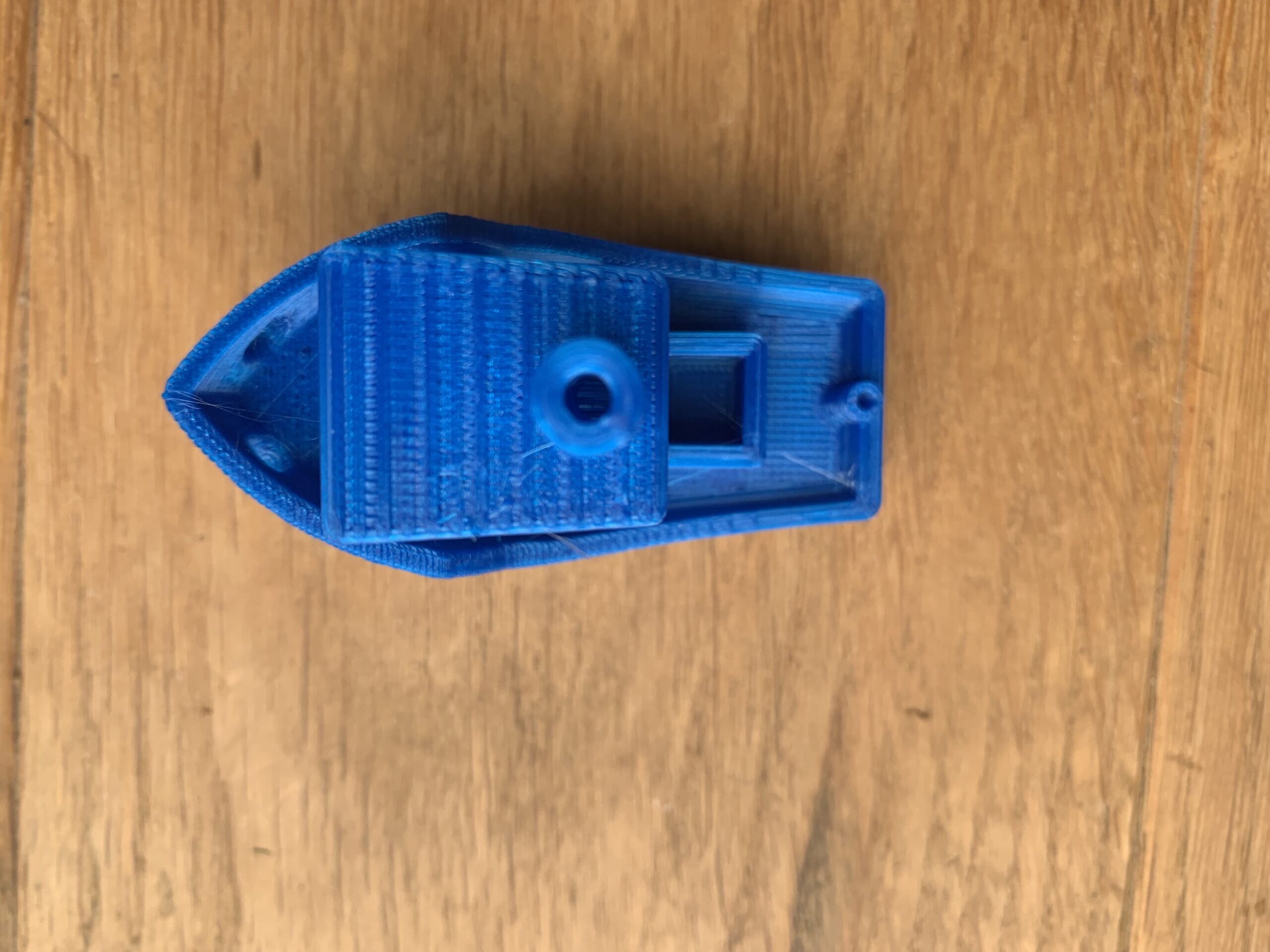

I'm still slightly confused, but definitely making progress. Using some blue (Prusa Extrafill Noble Blue), I've got the first layer calibration to a place I'm relatively happy and am now printing a Benchy as a test. But, all good.

However, when I've tried to swap back to the white PLA (Prusa While PLA), I'm back in a world of pain. I can't consistently run through the first layer calibration and interestingly the filament doesn't feed properly (clicking from the extruder). Can there be a problem with filament (genuine question)? The 4 part model that kicked this all off I did want to do in white and I did manage to print the first part (a quarter of the model) relatively well, about a week ago.

As always, any thoughts and input are greatly appreciated.

I do now have a greater understanding of my printer, so there are some positives.

Stuart

RE: Still Lost After Weeks Of Trying

After see your picture, i'm quite sure that your problem is clogging inside the heatbreak.

1. PTFE tube inside the heatbreak is shrinking, it should be 43.4 mm , if you measure it shorter than that, you should change it... i believe prusa give you one for spare in plastic bag.

2. there's might be lack of thermal paste on the heatbreak so the PTFE tube shrinking. Here the instruction when apply thermal paste on the heatbreak .

3. white filament often give you much problem. Filament jam, visible layerline, overextrusion. You want to use another color of filament to test your print.

RE: Still Lost After Weeks Of Trying

That is good benchy, the layer line is because of the filament (maybe moist) i have prusament galaxy black and sometimes that layer lines comes up too.

Anyway, if you have to reseated the PTFE tube to get this nice benchy, that means that PTFE tube is shrinking... now you know what to do if this issue happen again. You can make PTFE tube for spare using This tool

RE: Still Lost After Weeks Of Trying

@stuart, I’ve had a look at the thread but not seen it mentioned, what temp and speed are you running the prints at?

I had to slow down my pla prints significantly, and always run higher temps than stock, I even changed the default profiles for slower infill speeds as it alwys grinded on the long straight infill lines.

eg, 40mm a sec for infill.

235 for temp on pla

down to 50% speeds too.

you mention your go down to check the printer, is it not in a room you can monitor and react? One thing I do frequently is checking the printer nozzle at eye level and using the live tweaking to reduce the speed to 10 use a pair of edge cutters and at that speed you can get in and out with a surgical cut of wispy bits or even take off a blob of buildup off the head without stopping the print. Once surgery is performed, bump the speed back up, this process has saved a lot of prints, but you kinda need to be near the printer to hear it grind and react.

one thing I’ve noticed but I don’t see mentioned a lot, as the spool ages, the properties for the outer half of the spool and the inner half are often not the same, with prints needing to be hotter and slower the older the spool, so the difference between good fresh and going off bad is really small but can make or break the print.

RE: Still Lost After Weeks Of Trying

Sorry it has been frustrating (been there done that), one thing to check is to make sure the hot-end fan (the one that is upright on the left side of the hotend and should only spin when the nozzle >50C) is spinning, I got similar results on my mini+ when the fan stopped behaving otherwise agree with above that your nozzle seems too low on the streaked first layer and to try in the gray filament that worked on the big square.