Trianglelabs Titanium heatbreak

It popped up to me when browsing Ali. Anyone has any experience with these? They resemble Bondtech heatbreaks, have that choke throat above the thread to separate hot and cold zone better. Made from titanium alloy, which could make them a bit more fragile though.

There are positive reviews about them, and Trianglelabs are known to have better quality parts than other "chinesium brands". Could be alternative to Bondtech heatbreak, when Slice Engineering are somewhat dragging their feet bringing their own (they offer full hotend upgrades but not individual heatbreak).

RE: Trianglelabs Titanium heatbreak

It popped up to me when browsing Ali. Anyone has any experience with these? They resemble Bondtech heatbreaks, have that choke throat above the thread to separate hot and cold zone better. Made from titanium alloy, which could make them a bit more fragile though.

There are positive reviews about them, and Trianglelabs are known to have better quality parts than other "chinesium brands". Could be alternative to Bondtech heatbreak, when Slice Engineering are somewhat dragging their feet bringing their own (they offer full hotend upgrades but not individual heatbreak).

I have only had good experiences with purchases from Trianglelabs regarding hotend accessories. The offered titanium heatbreak is definitely more effective than the "Prusa steel pipe". The price is ok, but the delivery times...?

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Trianglelabs Titanium heatbreak

It popped up to me when browsing Ali. Anyone has any experience with these? They resemble Bondtech heatbreaks, have that choke throat above the thread to separate hot and cold zone better. Made from titanium alloy, which could make them a bit more fragile though.

I have had good luck with TriangleLab titanium heatbreaks for the E3D V6 and Volcano. I have had decidedly bad luck with 2 of TriangleLabs bimetal heatbreaks for the same. The internal fit and machining seem poor. The one-piece heatbreaks, heater blocks, and nozzles are very good.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Trianglelabs Titanium heatbreak

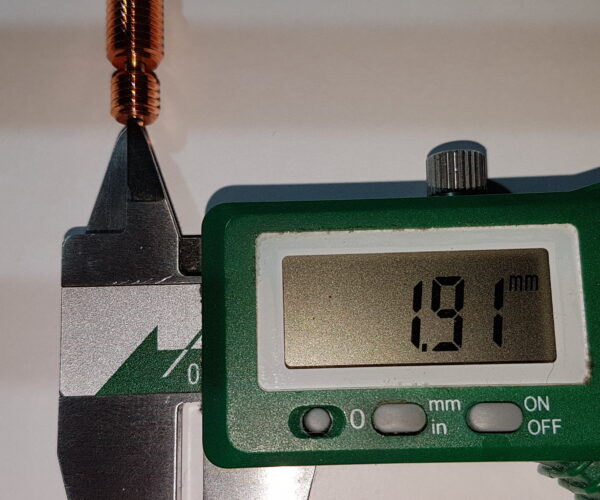

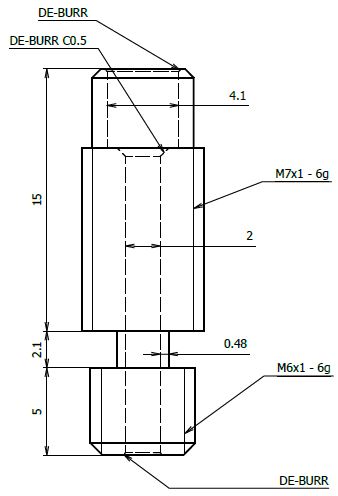

I have not tested the bimetal heatbreak on the printer, because the hole inside diameter of only 1.91mm is too small for me (due to the press-fit) and the hole is also 0.03mm out of round. The titanium variant is fine.

bitmetal inner diameter:

titan inner diameter (ok; smooth filament flow)

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Trianglelabs Titanium heatbreak

@karl-herbert

Odd. I will have to check the couple I bought. I have one installed.

--------------------

Chuck H

3D Printer Review Blog

RE: Trianglelabs Titanium heatbreak

It popped up to me when browsing Ali. Anyone has any experience with these? They resemble Bondtech heatbreaks, have that choke throat above the thread to separate hot and cold zone better. Made from titanium alloy, which could make them a bit more fragile though.

There are positive reviews about them, and Trianglelabs are known to have better quality parts than other "chinesium brands". Could be alternative to Bondtech heatbreak, when Slice Engineering are somewhat dragging their feet bringing their own (they offer full hotend upgrades but not individual heatbreak).

Hi

I have it since nearly 2 months, it works perfectly and also allows (on my clone) a proper hotend assembly avoiding leakage.

No idea how it works on a original mini, may be not effective as on a clone because of different heatblock design.

RE: Trianglelabs Titanium heatbreak

I will rework the hole of the pressed-in sleeve on the bimetal heatbreak to 2H7 and then test it on the Mini. It would be a pity not to use it, because it is otherwise well manufactured.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Trianglelabs Titanium heatbreak

@karl-herbert

It is good to have that capability!

--------------------

Chuck H

3D Printer Review Blog

RE: Trianglelabs Titanium heatbreak

Does the trianglelabs heatbreak use the same Ptfe tube as the original?

Or is it shorter like the Bontech?

RE: Trianglelabs Titanium heatbreak

@rainer-2

You have to shorten the vaccine.

--------------------

Chuck H

3D Printer Review Blog

RE: Trianglelabs Titanium heatbreak

Ok, how much? Any Instructions from Trianglelabs?

RE: Trianglelabs Titanium heatbreak

@rainer-2

You have to shorten the vaccine.

You have to shorten the PTFE tubing. I have COVID on my mind.

--------------------

Chuck H

3D Printer Review Blog

RE: Trianglelabs Titanium heatbreak

@rainer-2

28.7-30.7 depending on the flavor of printer you are using.

--------------------

Chuck H

3D Printer Review Blog

RE: Trianglelabs Titanium heatbreak

Ok, how much? Any Instructions from Trianglelabs?

Yes you should create a new inner tube: assuming it is the same length as Bondtech : here is the manual: https://support.bondtech.se/Guide/0.1+Heat-break+Upgrade+Kit/60 : for cutting the tube you can use this jig: https://www.prusaprinters.org/prints/3644-ptfe-tube-chamfer-and-cut-jig. What you could also do is replace the (3 piece) ptfe tube with the help of PC4-M8 couplers and go to a 1 piece boden see here: https://forum.prusa3d.com/forum/user-mods-octoprint-enclosures-nozzles/pc4-m8x1-25-bowden-pneumatic-connectors/

Stock MK4S with FW 6.2.6

RE: Trianglelabs Titanium heatbreak

I ordered the heatbreak and later asked Triangelab on AliExpress chat about the ptfe tube. They said to re-use the stock length tube. I did. The thick upper portion of the heatbreak sticks out maybe 1mm from the heatsink before it gets to the tiny tapered neck.

Seems to work well thus far, but I'm only a few prints in. Time will tell if it's the cure for my jamming problems (the extruder by itself wasn't).