RE: Revo Micro installation on my Mini+

I am not so sure the Capricor tube is all that much better. It works great, until it doesn't. I had it on a different printer (Voron Trident) for my reverse bowden.

I think Capricon do a specific tube for reverse bodens that has a wider internal diameter. I have a normal capricorn on my Mini and it works very well, the ID is smaller than the Prusa boden, which should make the filament travel between the extruder and hotend more predictable, as it won't bow when pushed.

RE: Revo Micro installation on my Mini+

Hi all,

After reading the post and the Heat creep post related to the Bondtech heatbreak, and the video from CNC Kitchen, I have a theory about the issue.

First, the problem most likely to occur in following conditions:

a) a low flow rate condition and/or high retraction frequency layer

b) using E3D Revo or Bondtech heatbreak, which is a better alternative for replacing the original one

c) printing PLA

What actually happening are:

1) The very well performed heatbreak stopping the back flow of heat from nozzle.

2) A rapid temperature change over a very short distance (a few mm) within the nozzle (ref to CNC Kitchen video)

3) When layers are in low flow rate condition with high retraction frequency, a thin layer of clog were formed near the rapid T changing region.

4) As Extruder keep feeding filament to the hotend with clog, Pressure inside the Hotend/Nozzle rise until the clog moved to the melting zone.

5) You can observe that the nozzle will start under extrusion in those layer for a while, then a lot of filament were push out from the nozzle and become a bad layer.

This is why @robee-shepherd 's suggestion work!!!!

And I think the fan isn't the problem. if you read the graphs in CNC kitchen's video, you will find that the rapid temperature changing region is within/near the heater cartridge (~14-16mm from Nozzle tips). The Heatsink is still cold. So I believe the hotend fan doesn't related to the problem.

RE: Revo Micro installation on my Mini+

My ongoing dialogue with E3D regarding this issue has now ended acrimoniously after so much time and effort to get a resolution. They have simply dug their heels in, referring to the terms and conditions and refusing to refund what would have gone toward some more V6 nozzles from them. Not now, not ever. I've gone back to the stock and it's working fine, as it used to. I have had a fantastic experience with the Mosquito hotend (not the shortcut version) on a MK3 so I'll be looking in that direction instead for hassle free nozzle changes with no hot tightening.

RE: Revo Micro installation on my Mini+

Hi

Sorry to bump this but is there a TLDR?

my mini makes clicking sounds from the extruder, so I am guessing along the lines of what other people were getting.

Is there a good length for the bowden tube? any gcode that should be used? a firmware that suits the revo micro and Bondtech extruder

Any thing else that I should do?

thanks!

RE: Revo Micro installation on my Mini+

The Revo is not a drop in replacement. Your options for “the clicking” or more specifically cutting the original Bowden thus making it too short is to replace with another 150mm length tube.

You could change the firmware (voiding your warranty), print new parts to stop the heat creep or new parts to resolve the cooling issues. You could crimp new (correct! connectors onto the thermistor (assuming yours is not broken already (yet)) but none of this will fix the flawed design as many other “expert” has proven (I would share the links but suggest you do your research and find the answers in this thread).

RE: Revo Micro installation on my Mini+

@dan-rh-jones The extruder clicking is because there is some restriction or blockage in the filament path. As @threepoint2 says, replacing the bowden tune may help but might not offer a long term solution because there are many problems that can cause it. PTFE tubes are not all the same and it would be advisable to source a good one that has reasonable clearance with the filament. PLA is prone to swelling when hot and retracting a swollen bit of filament can cause it to get stuck if the tolerance is too tight or the tube is poor quality and has too much friction. The first thing to try though, is to clear any blockages from the hot end. Try some cold pulls with some nylon cleaning filament (there are a few posts with some in-depth guidance on this). Even just loading some cleaning filament at 250℃ and then extruding through some more (move the E-axis in the settings menu) can help with a partial blockage. I would replace the Bowden tube as a matter of course because reducing the length is not a good idea and can cause the filament to get rammed during loading.

As @threepoint2 points out, there are other issues with the Micro that crop up for some people that slicer settings can mitigate to some degree, but the design has some inherent flaws. I also think the lack of a strain relief for the PTFE tube on the hot end can cause the PTFE tube to score and create a choke point.

Good luck. I sincerely hope you don't become one of us with unmet expectations because E3D really don't care as some here can attest to.

RE: Revo Micro installation on my Mini+

I have found one more little operational issue with the Revo, so posting it here in case it helps someone.

To facilitate quick nozzle changes, I went with a variation of this E3D start/end gcode suggestion. This has made cold nozzle changes easy, but it has a side effect when it comes to filament changing.

After having a solid jam when changing filament, I removed the nozzle and found a solid little wedge of filament stuck at the top of the heat break tube. I think what happened is that the Mini's filament removal programme does a short purge before doing a full retraction. Since the filament starts approx 18mm away from the melt zone, the short purge is just enough for it to pick up a little blob of molten filament from the hot end, which it promptly loses when the full retraction starts, leaving a blob behind that solidifies and blocks the path.

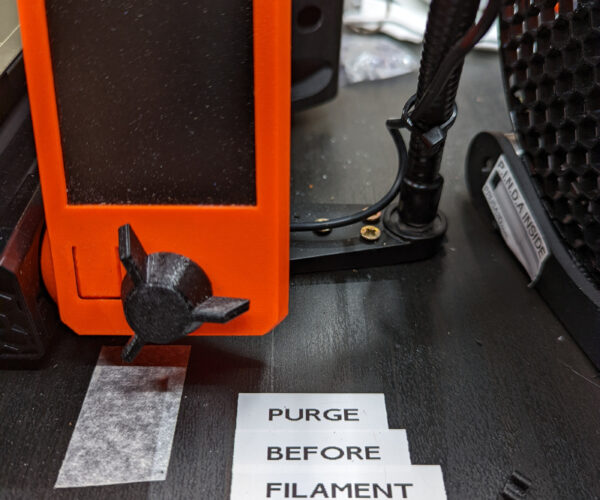

The solution is simple, and not too time consuming: simply do a purge before removing or changing the filament. That way, the filament starts in the hot end as the programme expects.

I've stuck a little reminder to my work surface: 😉

RE:

I really wanted to jump in here and say a massive thank you to you guys for all the work you've done investigating and resolving these issues. For context, I pre-ordered the Revo Micro and installed it with V1 of the mount as soon as it arrived. I got some ok prints, and then keep getting extruder clicking .

I tried to fix these by buying and installing the Bondtech Extruder, as I'd had no end of issues with the stock one. Yet this didn't solve my problem. I would be able to print a calibration cube, but anything taller/bigger would fail. Behold my Benchy graveyard:

No matter what we tried, be it temp, extruder steps... nothing worked and Benchys would always fail around the same point (save one that you can see which gave me false hope). We also noticed that the PTFE tube kept getting chewed up. It was perfectly cut using a jig, so the end was even when it went into the hotend, but you can see how it would look after a few failed prints. We thought the lack of strain relief was adding to the issues:

We printed Lichtjaeger's mount - cut a new PTFE tube etc, and FINALLY, for the first time in MONTHS got a finished Benchy. I'd been so close to kicking my Mini out of the window at this point.

However it had those issues with the pillars that a few of you have reported - so when I continued going through the thread and found the shared solutions, we gave it a try, and voila:

Comparing the two, side by side, the second one with the suggested changes of a) "Min Print Speed" from 15 to 20 mm/s. b) "Slow down if layer time is below " from 15 to 5 seconds. and c) "Retraction length" from default (2.0) to 1.8 mm resulted in a flawless Benchy. We were able to see the difference elsewhere, such as on the coaster pattern that appeared in the Prusa competition recently. The pink one is without those settings (it wouldn't print that far at all before, without the new Revo mount), and the purple is with them applied - it's night and day in terms of a difference:

So yeah - thank you so much for all the hard work and research. I gave increasing temps by 10 degrees a try, which didn't really resolve anything and caused other melty issues with most filaments, so now I have a new PLA profile that's got those 3 changes always applied. And also, no issues with ASA/ABS/PETG so 🤷♀️

You guys have saved my printer and enabled me to get back to using it again - so thank you. Hopefully the pictures might help others who turn up with similar issues.

RE: Revo Micro installation on my Mini+

Hi

Sorry to bump this but is there a TLDR?

my mini makes clicking sounds from the extruder, so I am guessing along the lines of what other people were getting.

Is there a good length for the bowden tube? any gcode that should be used? a firmware that suits the revo micro and Bondtech extruder

Any thing else that I should do?

thanks!

I also also appreciate a resume of this thread. I read it all but between the multiple reported issues of shorten bowden tubes, heatbreak failures and changes to the slicer in speed and gcode but there's not seems a final conclusion and E3D is being useless in providing support to this community.

I understand that it seems lazy but as a beginner I just installed this very carefully (took me 2 hours) to change nozzles in a more effective way since I had all kind of issues with the V6

RE: Revo Micro installation on my Mini+

I hate to say it, but the easiest fix for all my problems with my Revo + Bondtech Extruder (and my Bondtech heatbreak + Bondtech Extruder before it) was to just not use Prusament. 😔

RE: Revo Micro installation on my Mini+

As a TLDR for me, the fixes were:

- Use an updated mount (I used Lichtjaegers - the v2 from E3D may also do the job as well, but I've not tried it personally). Do NOT use the v1 mount or the tiny fan that comes with the Revo

- Ensure you're using the stock fan - especially on PLA which needs the cooling

- Update the profile you use in PrusaSlicer for PLA to incorporate these changes:

- a) "Min Print Speed" from 15 to 20 mm/s. b) "Slow down if layer time is below " from 15 to 5 seconds. and c) "Retraction length" from default (2.0) to 1.8 mm

That's fixed it for me. ABS and PETG printed fine anyway, but if you print a lot of PLA like I do, creating a duplicate Prusament PLA profile with the above has done the trick for me and I've printed a good kilo or two since getting everything fixed.

I hope that helps!

RE: Revo Micro installation on my Mini+

Funny, mine was to ditch revo and use a mosquito and any darn filament I want to use.

RE: Revo Micro installation on my Mini+

You're not wrong about this.

My story with the mini. Stock hot end consistently suffered from heat creep for me. I tried the bondtech heatbreak at first , didn't help. I was maintaining the PTFE tube shrinkage situation, still no help. I swapped in a mosquito, problem solved, the mini was the most reliable when I had that.

Fast forward to the Revo Micro. I hade a lot of challenges, I used Lichtjaegers because I wanted to revert back in case of any problems. The problems were huge with PLA, PETG was fine. I then decided to do use the Lichtjaegers mount with the stock Prusa Fan and at the same time I made the fan run at full speed. This seemed to work but I still have issues where the filament curls onto the nozzle during warm up and ends up causing issues sometimes. I still have the revo and the nozzle changes are a huge plus for me.

Funny, mine was to ditch revo and use a mosquito and any darn filament I want to use.

RE: Revo Micro installation on my Mini+

@kevman The problem is that E3D don't think there is a problem. I gave them a file of mine to test that I've had nothing but problems with and they say it worked perfectly. They sent a photo back of it mid-way through a print. I remain sceptical about it, and adamant that there is an issue but until enough people complain about it, it will never get resolved or even investigated.

I switched to a Mosquito on a MK3 and I'm thinking of trying it with the Mini as well since it allows cold, single-handed nozzle tightening with standard V6 nozzles that are a lot cheaper.

RE: Revo Micro installation on my Mini+

Yes- what I have read is they have taken a very hard stance on this product. Its almost as though they are offended by the people needing support , rather than trying to see if their baby is truly ugly. They had a solid reputation at the time this was released and I bought it with a lot of confidence in the company...but I feel as though I might want to get the E3d product out of my MK3 at this point.

With that said, I'm curious about your swap of the mosquito on the Mk3. I have the one from the mini sitting around , I printed one of the mounts here on printables. we can take this offline if you want but I'd love to know how the swap went for you and if you had any challenges.

@kevman The problem is that E3D don't think there is a problem. I gave them a file of mine to test that I've had nothing but problems with and they say it worked perfectly. They sent a photo back of it mid-way through a print. I remain sceptical about it, and adamant that there is an issue but until enough people complain about it, it will never get resolved or even investigated.

I switched to a Mosquito on a MK3 and I'm thinking of trying it with the Mini as well since it allows cold, single-handed nozzle tightening with standard V6 nozzles that are a lot cheaper.

RE: Revo Micro installation on my Mini+

@kevman No need to take it offline - let the world know about the issues and alternatives.

I absolutely love the mosquito. I started off with the shortcut version, which was a disaster despite it being offered as a direct upgrade for the MK3 by Bondtech. Slice Engineering have a different stance and offer it as a solution for softer filaments. I returned it and bought the full LGX version along with the Bondtech printed accessories (X-carriage etc). I wasn't expecting a huge difference but some models printed a lot better, especially those with curved overhangs (much smoother transition). It is expensive but you do get a better extruder as well. The only issue I have is that it is difficult to see the nozzle on the MK3 due to the size and orientation of the cooling shroud. I will probably replace all of my MK3 hotends and possibly try some of the user solutions for mounting them when I start. The Bondtech accessories are printed in some form of Nylon I think and they are very good quality but I like having a reverse Bowden, which isn't accommodated for. I remixed their top plate to take a pneumatic connector but the arms keep snapping off with PETG and ABS.

RE: Revo Micro installation on my Mini+

Thank you! what mount did you print ?

@kevman No need to take it offline - let the world know about the issues and alternatives.

I absolutely love the mosquito. I started off with the shortcut version, which was a disaster despite it being offered as a direct upgrade for the MK3 by Bondtech. Slice Engineering have a different stance and offer it as a solution for softer filaments. I returned it and bought the full LGX version along with the Bondtech printed accessories (X-carriage etc). I wasn't expecting a huge difference but some models printed a lot better, especially those with curved overhangs (much smoother transition). It is expensive but you do get a better extruder as well. The only issue I have is that it is difficult to see the nozzle on the MK3 due to the size and orientation of the cooling shroud. I will probably replace all of my MK3 hotends and possibly try some of the user solutions for mounting them when I start. The Bondtech accessories are printed in some form of Nylon I think and they are very good quality but I like having a reverse Bowden, which isn't accommodated for. I remixed their top plate to take a pneumatic connector but the arms keep snapping off with PETG and ABS.

RE: Revo Micro installation on my Mini+

@kevman - I bought the Bondtech X-carriage kit for Prusa MK3S. I'll print the next one!

RE: Revo Micro installation on my Mini+

@kevman No need to take it offline - let the world know about the issues and alternatives.

While I agree that you can discuss these things online, may I suggest that you start your own thread, in which that is the topic?

This thread is about the Revo Micro on the Mini+. Of course you can do whatever you want - but I feel that a new thread would be appropriate.

As for issues - just for balance - I have not had any beyond the tuning of the Prusament PLA above. My Revo Micro is staying very firmly in place.

RE: Revo Micro installation on my Mini+

I have had no issues with all of the mini hotends. I did replace three just to tinker but all are still fully functional with no heat creep. I print up to ASA and ABS regularly.

--------------------

Chuck H

3D Printer Review Blog