Prusa mini Fysetc clone - log of a journey

Hi All,

this post is just to share my experience with the fystec clone of the prusa mini.

First why a clone? since (lucky me) money is not the main driver I could buy the original one from Prusa, what make me the decision was the lead time, more than 2 months are really too much moreover I like building and tweaking stuff. So I bought the kit on aliexpress (spain store) and PETG parts from ebay (spanish seller) , one week later I received both, just in time before the severe Christmas lockdown here in Italy.

I assembled the whole printer thanks to the Fysetc video and pdf guide. Everything straight except the extruder shaft diameter too big that forced me to file it a bit.

So I started printing and what I got?

first print quite good, then a nightmare endless sequence of:

- poor bed adhesion

- oozing like hell

- heatblock leakage

- high odour even on petg

- nozzle always clogged

- underextrusion

- holes on top layers

- unreal stringing especially on PETG

- noisy bearings

- lowered down the temperature by 20c on all filament profiles to get a decent print.

after 3 weeks I was very angry (with me since I decided for an unsupported clone) I I've been really close to give up as every time I disassembled something to fix an issue something else turned out.

Then I decided to don't give up and try to improve the beast.

this is my current mod list:

- replaced the extruder by a geared bondtech clone, this boosted a lot the reliability of the printer, no more underextrusion nor holes on top layers. absolutely recommended.

- replaced the heatbreak with a bondtech clone (aliexpress), this allowed me a good assembly of the heatblock, I discovered that the heatblock on the clone is 0.5mm higher than the original one so it is difficult if not impossible getting a proper assembly of the nozzle to heatbreak. leakage, odour and clogs gone away. mandatory mod for every clone owner.

- avoid acetone or anything else "magic" to improve 1st layer adhesion. just keep the bed clean with hot water and dish soap avoiding finger on bed. No more first layer adhesion issues. of course remember to use PEI on PLA and powder on PETG.

- Since moisture is high where I live I converted a salad box with dryer salt and a filament clean filter to avoid moisture and dust on the filament spool.

- Silicone bed leveling mod. Nice, really nice. maybe the firmware doesn't need a perfectly flat bed but the feeling while seeing "Your printing bed" so flat is really good (at least to me). Ah, I need it as my Y carriage is tilted

- fan duct rev C, I reworked it to put the fan vertical it seems fine but I'm not printing PLA at the moment. let's see.

- Still working on bearing noise, most noise is due to the frame tilted. not sure I want to spend money for high quality rod and bearings.

Then I started tweaking the firmware, don't know why but I didn't need to broke the pcb, unsigned firmware are allowed on my clone:

- changed the hotend thermistor type from 5 to 1. now the stringing gone away and also switching back to stock filament temperatures profiles are allowing a perfect print quality (finally).

- changed extruder steps and direction according to bondtech clone

- enabled the SKEW compensation as I realised my printer is tilted on all axes due to tilted printed parts, thanks to it I'm now able to reprint and replace parts, my goal is disabling the skew by getting the frame straight.

- played with motor current, waste of time, stock profile are good.

- increased the hotend fan pwm as the clone runs at 3000rpm, now is 4500rpm (5500 is the maximum achievable by that fan), oozing gone.

that's it now it print very well, the feeling is that it is also reliable.

Resuming:

I would repeat the choice of the clone instead of an original one? probably not as I'm having a good printer after 2 months, waiting for an original one could be lead in the same result with almost zero effort. At the same time I'm not worried anymore since I'm now able to handle most of the issues I could get on a 3d printer. So in the end I'm still happy for the choice as I learned many stuff and now I'm confident on accuracy and quality of my prints.

Hopefully somebody find it useful.

Have fun!

RE: Prusa mini Fysetc clone - log of a journey

I came to the same conclusion:

I have been printing with one for months. It works, but the extra cost for an Original is worth it.

--------------------

Chuck H

3D Printer Review Blog

RE: Prusa mini Fysetc clone - log of a journey

Hey,

sorry for bothering you again. Found the Configuration_A3ides_2209_MINI.h file and managed to change the firmware to my needs. My stringing problem is completely gone after setting the thermistor to no. 11.

But with the modification of the hotend fan, I am running out of ideas... I tried several things and tried to understand how the prusa firmware sets the pwm value but I haven't found a solution yet.

How did you change the hotend fan speed?

It would be great to get some help here.

Best regards

Felix

"

RE: Prusa mini Fysetc clone - log of a journey

@menaku

sorry I didn't see Your question before...

I set this

static const uint8_t FANCTL1_PWM_MAX = 35;

in src/common/config_a3ides2209.h

I didn't find any other way.

RE: Prusa mini Fysetc clone - log of a journey

H

- replaced the heatbreak with a bondtech clone (aliexpress), this allowed me a good assembly of the heatblock, I discovered that the heatblock on the clone is 0.5mm higher than the original one so it is difficult if not impossible getting a proper assembly of the nozzle to heatbreak. leakage, odour and clogs gone away. mandatory mod for every clone owner.

Hi,

I also own a Prusa mini Clone by Fysetc and must say I love it. Is it perfect? No it is not! But then again the original isn't either.

Anyway I read that you installed the cloned bondtech Prusa mini heatbreak, I also ordered the one from Triangle labs and am wondering what you had to change to fit it on the clone. The heatsink is a bit different on the clone as the coupling isn't the same. I believe the threads are different and maybe even the diameter. Also on the clone the PTFE tube goes through the coupling all the way until the nozzle, on the Original and the Bondtech heatbreak there is a piece of white PTFE that is contained between the heatbreak and the flange in the brass coupling of the original Prusa mini. If you don't change the coupling how can you contain the first part of the PTFE tube? Or did you just use the coupling that came with the Clone and shoved the Blue PTFE tube (falter chamfering it) until the end of the Bondtech clone heatbreak? And if so did shorten it a bit as the original length would be a bit too long with the new heatbreak as it does not need to go all the way up to the nozzle?

If you did not shorten it did you change the e-steps?

Quick tip, you can order a more compatible heatblock (that won't block the fan) here:

https://nl.aliexpress.com/item/1005001414256208.html?spm=a2g0s.9042311.0.0.5fd84c4dvzZtLN

And these would be the correct couplings to use with the bondtech heatbreak but according to the seller it will not fit the heatsink of the fysetc clone:

https://nl.aliexpress.com/item/1005001405577637.html?spm=a2g0o.cart.0.0.24e63c008Xk5Lj&mp=1

Anyway, would love to hear from your experience.

RE: Prusa mini Fysetc clone - log of a journey

@fernando-t

I used the stock ptfe without cutting it, just push it until it reaches the end of heatbreak with no need of changes in the firmware, I redid the PID.

I placed this https://www.thingiverse.com/thing:4268489 on both sides of the bowden tube.

I had to replace the heatblock since in the first month I did a mess, I was a rookie and I learned how to properly assemble the hotend over the skin of the stock heatblock (and the stock thermistor plus all stock nozzles... 😇 ).

Anyway I choose to stay on e3dv6 standard heatblock and I don't regret. the only cons is the rear cooling fan that is not optimal, but who cares, I've added a second fan on the front side by using this https://www.prusaprinters.org/prints/39845-prusa-mini-rhd-fan-duct-rev-c-adjustable-heigh-ver , if You are interested on do it simply connect the red and black wires of both fans in parallel. Now cooling is perfect.

I can't be sure but many reported issues on using bondtech heatbreak together with stock heatblock, I suspect the thermal behavior is different and the e3dv6 heatblock seems working better while using the bondtech like heatbreak. At least mine is printing really well till now.

RE: Prusa mini Fysetc clone - log of a journey

@turro75

Hi, OK thank you for the update, hmm I already ordered the new heatblock.

I have read about some issue indeed, but I was assuming it was with the standard heatbreak of the Prusa mini in the V6 heatblock of the clone.

Will give it a test. regarding the issues with the tightening of the nozzle I must say never had any issues, but I watched a million videos on YouTube before my first attempt. :')

But I always do a warm tightening.

Regarding the PTFE tube, did you chanfer it before you installed it?

Regarding the Fan, yep I am already using that one, huge improvement, when I installed this one I also noticed that the standard fan duct was melted a bit. I am planning of setting them up in paralel. Do you het a picture on how you splitted it?

RE: Prusa mini Fysetc clone - log of a journey

I replaced the entire hotend last night -> 100% improvement in print quality. I have not tried PETG but suspect it will also suspect to will print better with this. FYSETC's hotend is pure garbage.

--------------------

Chuck H

3D Printer Review Blog

RE: Prusa mini Fysetc clone - log of a journey

@cwbullet

Which hotend did you use? And which heatbreak?

RE: Prusa mini Fysetc clone - log of a journey

@fernando-t

I replaced it with a Prusa Mini hotend I bought off eBay foe $15. It was jammed. I removed the jam with a tungsten rod and it works now.

--------------------

Chuck H

3D Printer Review Blog

RE: Prusa mini Fysetc clone - log of a journey

@cwbullet

And which heatbreak?

I Must say the clone stuf on mine do work OK, but just want to upgrade it. Must say the Fysetc MK3S comes with better quality stuff. I replaced the bearings on that one with IKO's and used the YTP ones that came with the MK3S on th Prusa mini and that was a Huge improvement. Now planning the Upgrade of the Hotend with the one I posted above and the Trianglelabs heatbreak I already have. Hope I do not run in to issues like Turro75 mentions. Last upgrades I want to do is de second fan on the original place and IGUS bushings for the LM10LUU on the Z. Amy experience with that?

Owh and I think I will order a smooth PEI sheet for PLA and will keep de textured for PETG etc.

RE: Prusa mini Fysetc clone - log of a journey

@fernando-t

I used the standard Prusa Mini Heatbreak. I have one with bondtech - it jams less for me. I just have not upgraded them all.

--------------------

Chuck H

3D Printer Review Blog

RE: Prusa mini Fysetc clone - log of a journey

@cwbullet

Did you have any issues with the Bondtech heatbreak and the original prusa mini heatblock? Or are you using the bondtech heatbreak with the v6 Heatblock?

RE: Prusa mini Fysetc clone - log of a journey

@fernando-t

I use the Bondtech with a Chinese copy of the Prusa Mini hotend. It has had fewer jams. No quality difference,

--------------------

Chuck H

3D Printer Review Blog

RE: Prusa mini Fysetc clone - log of a journey

@fernando-t

I use the Bondtech with a Chinese copy of the Prusa Mini hotend. It has had fewer jams. No quality difference,

Something like this:

https://nl.aliexpress.com/item/1005001414256208.html?spm=a2g0s.9042311.0.0.5fd84c4dvzZtLN

RE: Prusa mini Fysetc clone - log of a journey

Regarding the PTFE tube, did you chanfer it before you installed it?

Regarding the Fan, yep I am already using that one, huge improvement, when I installed this one I also noticed that the standard fan duct was melted a bit. I am planning of setting them up in paralel. Do you het a picture on how you splitted it?

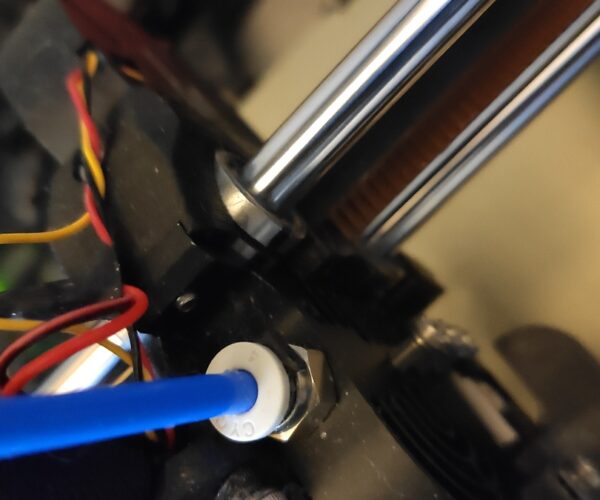

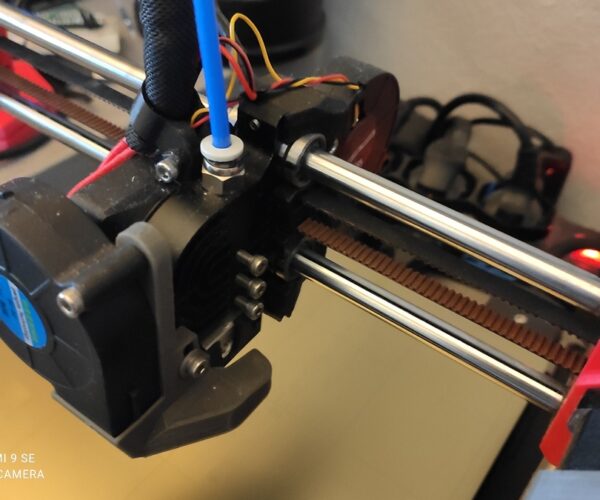

I chamfered the ptfe before assembly it even if I'm not sure it is so important, while in the stock heatbreak (and in the original mini heatbreak) the end of ptfe is in the heatblock, in the bondtech clone heatbreak the ptfe ends in the heatsink allowing safety even at higher temperatures. I used a cut tool taken from thingiverse, honestly I don't remember which one, I attached the photo.

the second fan is a standard 5015 fan without yellow wire, I connected black and red of both fans together.

If You are able to recompile the firmware increase the hotend fan speed, I noticed zero jamming after increasing it from 3000 to 4200rpm. Otherwise replace the fan with a 7-8000rpm.

RE: Prusa mini Fysetc clone - log of a journey

@fernando-t

No, I order this one. I order the whole piece because I can replace them as a unit.

--------------------

Chuck H

3D Printer Review Blog

RE: Prusa mini Fysetc clone - log of a journey

@cwbullet

Hi, OK yes is actually the same, the only difference is that I am using the Titanium heatbreak from TriangleLabs and the original Heatsink of the clone. So I think in my case it will be OK. I was worried about reports of the bondtech heatbreak not fitting correctly in the original prusa mini heatblock. But since the BondTech is designed to replace the heatbreak of the original Prusa mini (mening with the original prusa mini heatblock) I hope what I ordered will work. What you are reporting lead me to believe it will be the case as the only difference with mine is that the heatbreak is from TriangleLabs but similar to what you used.

if somehow it does not work I will order the same as you did.

Thank you for letting me know it is working well on you end!

RE: Prusa mini Fysetc clone - log of a journey

@turro75

Wow! Thank you for the extensive info!!

I see you have a better interaction of the fan, on mine the angle of the fan is bigger causing some issues with the cables not being long enough.

Th only drawback of your fan from what I can see is that it is close to the heatsink and therefore less efficient in sucking cool air as it will suck in the dissipated heat of the heatsink.

I am planning to put in some connectors between the fans and the cable for servicing purposes. That way I can unhook the fans if I have to uninstall the hotend etc. but I am still looking for the correct connectors. On my ender 3 I used those pin connectors used in those arduino prototyping wires but did not like that.

The fan is a 5v one? do you have a link to the one you used? regarding recompiling the firmware, I guess I could od it, didi it all the time for the Ender 3, but I rather not do it on the Prusa as I went with the Prusa to avoid all the thinkering. I just want to stick to the essential mods to compensate for the shortcomings of the design and leave it further as stock as possible.

So I think I will go for a Fan replacement, can you recommend one? The 7- 8000 rpm you mentioned.

I also have a Fysetc MK3S clone (which is a beat of a Printer, much better quality then the mini clone) which I want to keep as close to the original as possible and a BLV MGN CUBE, that one is my tweak and try printer, but am still building it and it uses DUET WIFI = REPRAP firmware.

RE: Prusa mini Fysetc clone - log of a journey

@Turro75

Would this fan be OK:

It is 5800 RPM, not sure if that will be enough.