Different Hotends

Hi all, like many of us trying to get this little machine to print decently on a regular level I've grown a little frustrated with the underextrusion problems, most likely being caused by the design of the mini's hotend.

I had blobs of filament under the ptfe-tube in the heatsink even after trying to shove the hotend as far up as possible and so on.

Has anybody used a different hotend like the E3 V6 on a mini yet? Direct drive extruder won't likely be happening due to the cantilever design I guess, because the wait would probably be too much for the x-axis.

Thanks and have a nice day!

RE: Different Hotends

Some folks have posted comments on it, but I have not seen any confirmation yet. I suspect someone will try it.

--------------------

Chuck H

3D Printer Review Blog

RE: Different Hotends

favourably somebody who already owns a mk3 and got an e3d v6 laying around. 🙂

RE: Different Hotends

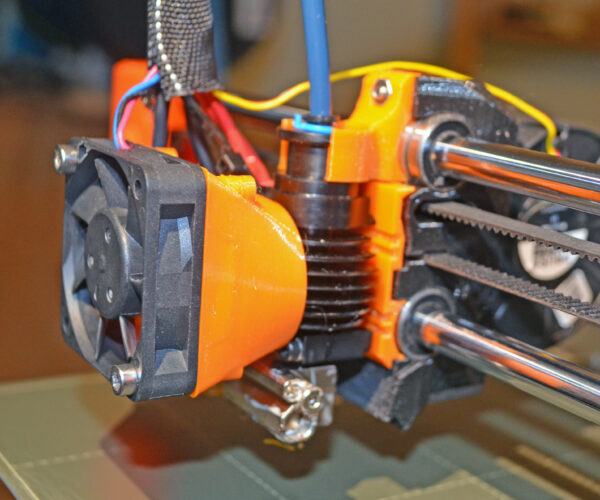

https://www.myminifactory.com/object/3d-print-original-prusa-mini-e3d-rc1-114657

Obviously, this guy did it.

--------------------

Chuck H

3D Printer Review Blog

RE: Different Hotends

uh damn, thank you charles, i looked around a bit and couldn't find an example!

RE: Different Hotends

@strandedbandit

No issues. I will keep looking for others.

--------------------

Chuck H

3D Printer Review Blog

RE: Different Hotends

I get 404 error for all Minifactory objects, weird.

But there are two others I know of. https://www.thingiverse.com/thing:4130862 and https://www.prusaprinters.org/prints/31006

RE: Different Hotends

@bobcousins

sweet, these look very promising, too! 🙂

RE: Different Hotends

@bobcousins

Nice! It would print great with Polycarbonate.

--------------------

Chuck H

3D Printer Review Blog

RE: Different Hotends

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

RE: Different Hotends

@jasii

That looks very sexy, but the retail price is pretty steep.

RE: Different Hotends

@strandedbandit

If it is like the mosquito, it worth every penny.

--------------------

Chuck H

3D Printer Review Blog

RE: Different Hotends

Quick question - is there anything that needs to be done firmware-wise when hotend is changed, in case of MINI? Providing 40 W heater is used and fans have the same pinout. I know if you are at the point of changing hotends and extruder motors, that's pretty substantial modification. I am just curious what can be set up without compiling own firmware and wok with slicer settings and startup gcode to set values.

RE: Different Hotends

Quick question - is there anything that needs to be done firmware-wise when hotend is changed, in case of MINI? Providing 40 W heater is used and fans have the same pinout. I know if you are at the point of changing hotends and extruder motors, that's pretty substantial modification. I am just curious what can be set up without compiling own firmware and wok with slicer settings and startup gcode to set values.

As long as you do not use the high-temperature thermistor, no. It worked out of the box for me.

--------------------

Chuck H

3D Printer Review Blog

RE: Different Hotends

Have you modified the extruder of your MINI - and if - which extruder and which additional modifications?

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Different Hotends

I added a mosquito hotend, It printed well, but I found that the Mosquito was better on my MK3Ses because they can operate at a higher temperature. There was literally no reason to for me to use a Mosquito on the Mini. I like to manufacturer hotend.

--------------------

Chuck H

3D Printer Review Blog

RE: Different Hotends

@clemens-m

I have added the Copperhead to my MINI. I use the original thermistor/heater. Stock firmware.

I only had to design the mount, which uses the stock mounting screws, and recalibrate 'Z' + first layer.

Notes:

- The hotend had to be mounted 'sideways', that is, parallel with the X-axis because in standard perpendicular mode it would interfere with the stock X-carriage which I did not want to change.

- A new PTFE tube has to be used regardless because the stock one would be too short once you removed the compression sleeve on one end

- I added a pass-thru festo fitting on the extruder (designed M8-M10 coupler to mount) so a single PTFE length, rather than the current three.

- The single PTFE can be easily tightened (re-seated) over use as it presumably shrinks

- The single PTFE design also eliminates four potential gaps or areas for clogs/jams

On price, at $100 complete, the Copperhead sits between the Mosquito and the E3DV6, however, it is modular so you can get the Rep Rap 1.75 variant heat break/block for around $55 and screw it into an existing E3D heat sink.

Just some thoughts....

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)

RE: Different Hotends

The funny thing is, that my Mini printed excellent out of the box. I still have no problems with the original extruder and heatbreak. I will wait and watch if I suddenly have issues with the extruder - then I will think about it.

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Different Hotends

@clemens-m

see i hat grave extrusion problems, tried all the solutions going around, even upgraded to a bondtech heatbreak. nothing really seemed to give me more than 2 hours of solid printing until the extruder started clicking again due to some clot in the hotend. i'll tinker some more, learning my ways around that machine but if all else fails, i'll try and upgrade to a different hotend.

RE: Different Hotends

@clemens-m

Agreed, my MINI is also 100%, with PLA. When I switched to PetG, which is what I pretty much use exclusively, I started to get occasional clogs and jams while printing or unloading of filament (Prusament) and some first layer issues. I would take apart the PTFE tubes, to clear the jam, then reseat them and it would be fine, for a while, then reappear. So far so good with the Copperhead but it has only been going for one week. Time will tell... Jerry.

- MK3s w/Mosquito Hotend- Mini w/Copperhead Hotend- XL - 5 tool -OpenScad -3d Builder -FreeCAD -Alibre -OctoPrint/x3(Pi3B)