RE: Bondtech Extruder for Prusa MINI

@oxygen

That is what I use.

--------------------

Chuck H

3D Printer Review Blog

RE: Bondtech Extruder for Prusa MINI

@adam-prchlik

I've learned a bit about bed adhesion in the last few days and, oddly, it's counter to what you've mentioned. While listening to Thomas Slanderer, he made mention of increasing first layer height, and being sure to really squish it down on the print surface. Additionally, I read that slowing down the first layer could help increase bed adhesion. Increasing my first layer to the max .4mm (my nozzle diameter,) and doing a fresh first layer calibration until the rectangle printed as a solid sheet has solved the issue for me. This is in combination with the brim settings I mentioned previously (I think.)

I am printing with three different types of TPE (ThermoPlastic Elastomer,) two of which are TPU (ThermoPlastic Polyurethane,) which is a subtype of TPE. The two TPU's I am using are Flexfill 98A, and Sainsmart TPU. The third flexible material I am using is from Filatech, and is rather unique, being described as follows, in comparison to TPU, and other TPE's: "FilaFlexible40 has higher resilience (more rubbery), better performance in a wide range of temperatures, easier and more stable printing, higher chemical resistance and also UV resistance." Indeed, this stuff is rubbery, like the gummy sole of an approach style climbing shoe. Very interesting stuff.

With all three of the above flexible materials, increasing first layer height, and squishing it down, has proved to be a working formula for achieving proper bed adhesion. Importantly, I am printing on the powder coated, rough texture print sheet, as recommended in the previously posted guidelines.

Also, I came across an interesting comment while perusing github the other day, regarding the Bondtech extruder (which I own, along with the heatbreak, and plan to eventually install.) Here is a portion of it:

"Edit: The BondTech upgrade for me was a last resort fix. There are going to be other issues that crop up due to this upgrade and I believe I have found one or two already. The BondTech extruder is strong enough to separate the press fittings from the PTFE tube over time if there is a partial clog in the nozzle, so there is that. Oh, this is partially caused by the low tolerance of the inside diameter of the PTFE tube. Hundreds or thousands of retractions will create just enough pressure in the tube for it to work itself out of the press fitting given the increased strength of the new extruder. The extruder is intrinsically tied to the capabilities of the hotend, so there is a ton of room for error in that regard. The small E3D hotend absolutely cannot handle filament that out of spec which the BondTech extruder is capable enough to ram through it with serious consequence. This can be partially mitigated in the slicer by reducing the number of retractions, this is not a fix but rather a time extension on the inevitable issues that are going to crop up. (This can be corrected by a planned maintenance cycle, maybe.)"

Seems to make some sense, and doesn't appear to be anything to be overly concerned about, assuming the required maintenance is performed. Left ignored though, it seems it could become an issue. I've not seen anybody mention this elsewhere. Can someone with more experience using the Bondtech extruder comment on this? Are others here in agreement? I would like to have full confidence in this modification before eventually going forward. This is one instance where I want to avoid, "building my wings on the way down."

RE: Bondtech Extruder for Prusa MINI

@24kjames

I had a partial clog last week and the Bondtech extruder did push the PTFE tube out leaving behind a very lonely olive. I was printing a benchy with a 0.25 nozzle (just for curiosity). It is much more grippy and less likely to slip, which I guess is partly why it's better. 😁

RE: Bondtech Extruder for Prusa MINI

So I have the Dondtech extruder in now for about a week. and I am starting to get some weird issues.

Not using any flexibles at the moment, just PLA and PETG.

The prints originally were printing great, but in the last 2 days when I used Galaxy Purple Prusament I started getting the filament being ground by the gears in the extruder housing, normally after an hour or so into the print, sometimes longer..

I just did another print and it was 75 percent done.. I heard clicking and then after a 10 min the print head was above the print with no filament being extruded. I stopped the print and sure enough, the gears had ground the filament almost in half, so much so when I pulled out the filament it broke.

As I said last week everything was fine.. I tightened the spring all the way and then backed it of 2 turns and havent messed with it since, I changed out the filament to a cheaper brand.. and so far its printing ok.. but I am expecting it to start the click click sound soon.

My Mini has: A SuperPINDA + Bondtech Heatbreak + Bondtech Extruder installed

RE: Bondtech Extruder for Prusa MINI

@steve-smith

What temperature are you printing with? I also experienced clicking with the prusament galaxy recently with the bondtech upgrades and had to raise the temperature to 218C it's better with a brass nozzle, but kind of obvious with a hardened steel one.

I'm also having issues with the first layer since the heatbrake and extruder upgrade. The extrusion is kind of weird, if the first layer is a bigger surface I can see "waves" in extrusion. Already calibrated the first layer multiple times, but I suppose that somehow when printing the slow first layer, it kind of overextrudes while in between the layer is a bit too thin, then comes the next few lines, where it blobs again, and so on... Did reduced the flow from 95 to 90 and it kind of helped a bit, plus raised the temperature also to 218, but still kind of messy, not even.

RE: Bondtech Extruder for Prusa MINI

@peter-susan

Temp is 215 I am using PrusaSlicer and havent messed around with flow rate or temp.

I will try bumping up the temp a little and see if it solves anything.

Appreciate the help.

My Mini has: A SuperPINDA + Bondtech Heatbreak + Bondtech Extruder installed

RE: Bondtech Extruder for Prusa MINI

@steve-smith

Thats what i've expirienced with original extruder half a year ago... and it was all about (semi) cloging of the "printing head". Problem for me was mainly in the gaps on both sides of heatbreak.

Nozzle seemed tighten enough, and also PTFE tube seemed that sits on top ... but i found ring of plastic on both places. So my thought was that stream of molten plastic can create vortex rings around these gaps and a that also creates additional resistance... over time some of the plastic got harder / burned / more heat resistant ... at begining i was getting underextruded prints - from outside they looked ok, but it was like crumbling cookies 😀 ... later i've got all that grinding holes to filament, clicking and everything 🙂

Be cautious of rising temperature in order to push thru filaments when using PLA and PETG ... some brands, colors, types have chance to burn / harden even more and you can trap yourself even more

RE: Bondtech Extruder for Prusa MINI

@adam-prchlik

I have also found that raising the temeperature to get past a clog can create a clog by adding heat creep.

--------------------

Chuck H

3D Printer Review Blog

RE: Bondtech Extruder for Prusa MINI

What a coincidence. This clicking and clogging just happened to me over the last couple days, right as switched from the various TPE's, back to PLA. I was fighting the inconsistent bed leveling issue due to temperature, and then the clicking began during a print. Three more times I cleared the clog, leveled, and got similarly failed prints. Something with both of these issues colliding resulted in dents, and scrapes in my smooth print sheet. From smooth sailing, to dead in the water, I couldn't print due to clogs, under extrusion, the auto bad leveling, extruder clicking.. I was mildly dismayed, and so read the forums for a few hours looking for answers. I suspected installing the Super PINDA would address the leveling, and after reading the forums I decided the remaining problems were all likely symptoms of a single issue, shrinkage of PTFE tube #4, the shorty in the hot end. SPINDA was a breeze to install. Next, I manually purged the clog, performed a cold pull, and then removed PTFE tube #4. Comparing it to the spare, indeed it had "shrunk" over a mm in length, and that loss was redistributed as width, because it was definitely chubbier than the spare too. (I suspect it's possible we aren't actually seeing shrinkage here, but instead, normal compression of the PTFE tube upon installation, and then prolonged heat exposure eventually casting the tube in its compressed form, resulting in failure.) I dropped in the spare, reassembled, and ran the first Z cal which looked good. However all Z cals I've done looked good after dialing it in, evening while experiencing problems. The issues described above would only occur on the ensuing print, and during the first one to three layers. So I ran a test print. Immediately I could see something was different, actually everything was different; it was printing, and printing meticulously. Everything is back to (better than,) normal and the SPINDA, while unassuming, really is a an upgrade worthy of the, "+." Print came out absolutely rock solid, the best of that design yet (in PLA.) I'm going to order more PTFE and cut about 50 spares to have on hand. It's a simple, quick, and easy maintenance procedure, with profound effects. Funny all the problems cropped up coincidentally when I switched back to PLA. I still have a near sterling record with flexibles on my stock Mini. I think where the Bondtech may come into play, is if I decide to get into carbon, are other blended filaments, and at that point Ill be adding a whole new hotend too. For now though, I'm just gonna keep pumping out the prints (once again.) This marks a new level of confidence I have in this machine. I am truly impressed.

RE: Bondtech Extruder for Prusa MINI

@24kjames

Oh, this is partially caused by the low tolerance of the inside diameter of the PTFE tube

Is this for the bowden tube, or just the hotend tube? I've got the Bondtech extruder installed in addition to the Mosquito hotend, and I ran into this issue last week. Luckily the bowden tube just unscrewed itself from the extruder, so I didn't have to replace the tube.

On the hotend I've got a capricorn tube cut to size, which should have a better tolerence from my understanding. Wondering if it would help if I had a capricorn bowden as well.

Also, did you find that information on the buddy firmware github? I'm curious to read more about this.

RE: Bondtech Extruder for Prusa MINI

@amdragon

Pardon me. Yes, that is where I found it. I meant to link to the source of that quote when I posted it.

[FEATURE REQUEST]Signed firmware for Bondtech modifications #767

And here is a direct link to the comment by "derenma," from which I quoted.

And from what I've seen, yes, it appears you may have better luck using a single piece Capricorn for the Bowden as well, and in combination with the PC4 M8x1.25 Bowden Pneumatic Connectors. However, and you'll need to confirm this for yourself, I think the cap tubing will be .1mm smaller ID than the stock PTFE, but this is apparently accounted for by the tighter tolerances. Note, eventually I may go down this road, but I currently have no personal experience with this. I am only sharing what I've loosely gathered while tending to other issues. (Stock MINI+ is doing everything I need, for the moment.)

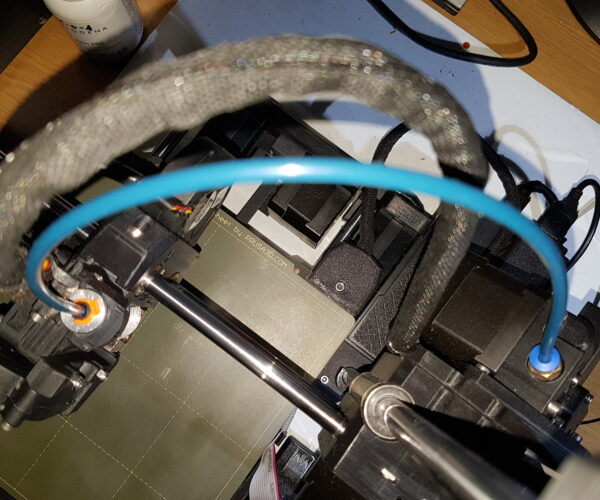

Photo is from karl-herbert, and can be found in one of his posts on this page.

RE: Bondtech Extruder for Prusa MINI

I'm really struggling with my Mini since I've upgraded to the Bondtech bits... I just can't get a consistent print out of it. I'm experiencing over/under extraction, heat/transfer issues, clicking, etc... I'm a bit lost by now, as I've tried everything I could.

I'm also having issue with the new Super PINDA. First of all, if I position it correctly, it gives a first layer hight about -1.970 with the smooth sheet, and I can't get the textured sheet configured, as the limit is -2 tops. If I raise the PINDA, then the self test Z axis calibration fails.

The first layer calibration is faulty with the bondtech extruder, as the esteps are not configured, so I have to run the gcode from the source code modified with the esteps to have a decent first layer test.

When finally get the point where I could print, it's really inconsistent and seems like the nozzle clogs as there are burst of blobs coming out after a decent under extraction.

I took the whole hotend apart, cleaned throughout (cleaned every thread and hole, inside-outside, like brand new), and instantly after I made a perfect print. The one after was a bit more faulty and the one after these are the same crap, layered, ugly, stringy.

I'm wondering, if my thermal paste rated until only 200C can be an issue what I used when I changed the heatbreak? I would be surprised if there would be more than 200C under the heatsink.

RE: Bondtech Extruder for Prusa MINI

Do you have a picture of your hotend? I wonder if the nozzle isn't touching the heatbreak and filament is building up in the gap there.

RE: Bondtech Extruder for Prusa MINI

@robee-shepherd

Actually that was the first thing I was looking into. I'll post the picture, but it's printing right now. The gap is there of course, and as it is the bondtech heatbrake, it'a kind of hard to achieve the opposite. I assembled it as usual... nozzle in 100%, then a half turn back, and then the heatbrake, nozzle handtight, back into the heatsink with paste, thermistor, heater into the head, heat it up, tighten the nozzle down, etc.

I recalibrated the extrusion multiplier with some calibration prints, and seems like 0.98 is a good number I'm using with this filament. The actual print was flawless and the sizes were spot on, so I'm printing a low tolerance bag clip right now. The first one did warp, so did a heatbed level visualisation also and looks like there was almost 1mm difference between the left and right side. I adjusted the mini's screws, so it's now leveled and seems like the second adhering and printing perfectly... nearly finished, but it's looking so far so good.

The previous print I showed is actually a not-so-uniform thin wall which requires a lot of retractions. I was wondering, if I only experienced this issues with my more delicate prints which are retraction-heavy and maybe it is the case. The simplier, more bigger prints are working fine as it seems.

Can it be, that with the bondtech extruder, over-retraction (default 3.2mm if I remember correctly) indicate air into the hothead causing disturbance and micro clogs in the nozzle, what generates under extraction, then the pressure from the pushing filament "frees" it up generating a blob, so at that moment it overextracts?

RE: Bondtech Extruder for Prusa MINI

Can it be, that with the bondtech extruder, over-retraction (default 3.2mm if I remember correctly) indicate air into the hothead causing disturbance and micro clogs in the nozzle, what generates under extraction, then the pressure from the pushing filament "frees" it up generating a blob, so at that moment it overextracts?

I don't know, I think this is more likely to happen if there is moisture in the filament.

I only had to run the provided gcode for both the extruder and heatbreak every power cycle, and mine worked perfectly (well almost, with the new Super PINDA they really do work amazingly).

RE: Bondtech Extruder for Prusa MINI

@robee-shepherd

I started up the Sunlu drier 3 hours ago, will print this thin stuff again if it finishes with the clip. It should be dry by then, so will see.

I installed the super pinda too, but unfortunately I only experienced weirdness from it, namely, that at the prescribed height (0.9mm), it requires the Z axys to be as low as -1.920 with the smooth sheet, so I can't calibrate my textured one, as it is thinner and -2.000 is the limit... If I raise the probe, then the selftest fails on the Z axis... really strange :/

RE: Bondtech Extruder for Prusa MINI

this thin model still turned out to be shit though, even after 6hrs of drying 🙁

RE: Bondtech Extruder for Prusa MINI

off-topic: I have placed 1.5mm between the tip of the nozzle and the SPINDA otherwise i could not reach the depth needed when i switch to the textured plate

Mini with FW:4.4.1 + SuperPINDA + Bondtech Heatbreak + PC4-M8 couplers + 1 piece boden

RE: Bondtech Extruder for Prusa MINI

@oxygen

that was my experience also, but this way the self-test fails for the Z axis for me

RE: Bondtech Extruder for Prusa MINI

@oxygen

that was my experience also, but this way the self-test fails for the Z axis for me

The distance for the Super PINDA does seem to be a lot more critical than for the MINDA. Mine didn't fail self-test but too close to the bed (low down in the mounting thingy) and I had the same issue with it being 1925 out of the maximum 2000, and too far away from the bed the nozzle would hit the bed and push it down slightly, then it would fail the test.