Weird slicing behaviour

Hey guys,

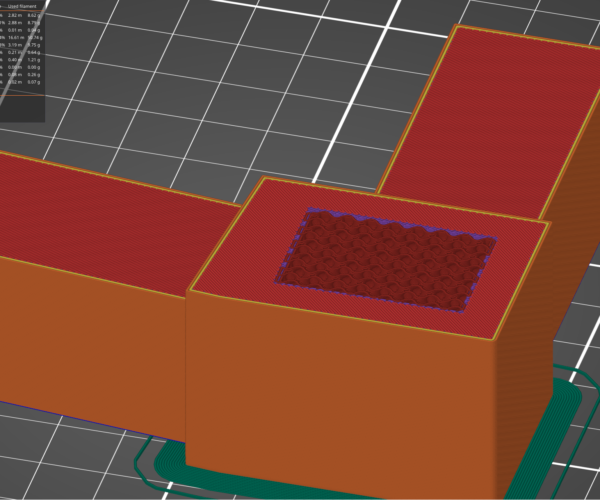

I have some trouble with the stability of this design (it's a connector for square tubing) and while looking through the sliced model i noticed, that the model gets closed at a point where more is to be printed on top [marked by the black arrow in the second image]. Is this intended behaviour and if so -why ?

The reason I'm wondering is, that that point is where the third arm breaks of easily - my suggestion is, that the inter layer adhesion is worse printing on the already closed surface and keeping printing onto the infill material. Also this results in some weird shell stacking (at least weird to me)

Let me know if more images or info is needed

Thanks in advance,

Chris

RE: Weird slicing behaviour

I admit I'm not totally sure I know what I'm looking at here and how picture 1 relates to picture 2. In general, for well-grounded advice it's better to post a zipped 3mf project file, as it contains both the STL and your settings.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/