warping in mid air

I’m not sure how to fix this problem, it warps so much that it eventually hits the superPinda sensor and it dislodges the print. Tried reducing temp (maybe less temp delta == less warping) reducing bridge gap speeds, fan is always at 100%, tried reducing global speeds too when it gets close to this part of print. This kind of warping seems like it became worse / problematic when I upped to a 0.8mm nozzle (this wasn’t so bad before with my 0.4mm)

Will continue changing slicer settings until I find something that works here. (maybe just orient the part so it doesn’t hit the pinda sensor, and hope the nozzle can “force it down” without dislodging the print)

info:

PLA (prusament, gray, might have some moisture in it, prints fine otherwise)

MK3S+

205C nozzle temp, 60 bed temp

using ikea lack enclosure, but might try make that hotter / more airtight.

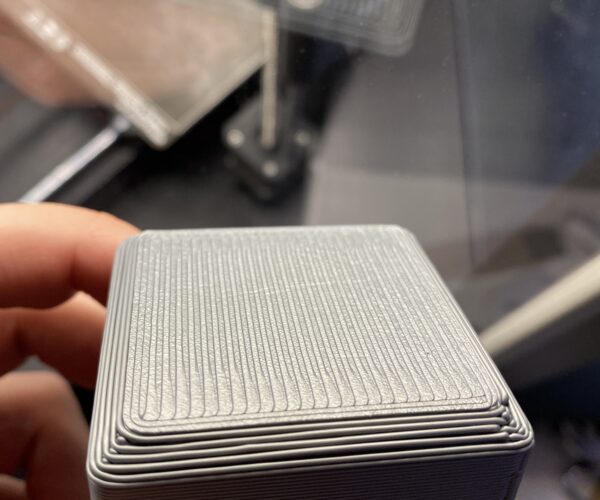

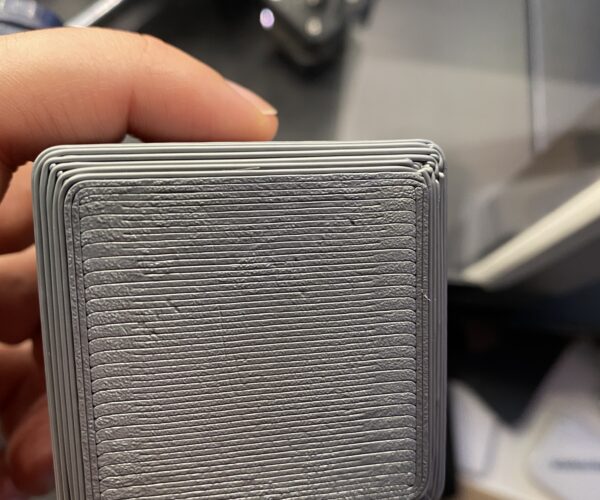

Please show us the bottom of a failed print.

Cheerio,

underside

Here is the bottom of the latest failed print, it looks a bit loose in the middle, using the textured plate, but maybe that’s a bad idea with PLA (I remember it worked fine), the gluestick might have made things worse though… will try the clean side next. and lower z-level adjustment too

Just thinking aloud here... Warping is mostly caused by fast filament cooling down (compared to the rest of the print). Now, this "handle" has less material than box walls and also handle will cool faster because it's more open to surrounding air (compared to walls, where current layer is kept warm by the layer below)... In short, I would try with lower fan speed.

[Mini+] [MK3S+BEAR]

Slowing print down worked, but another issue came up...

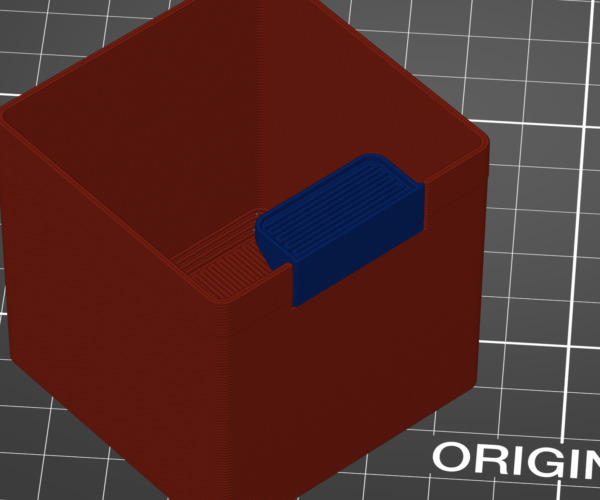

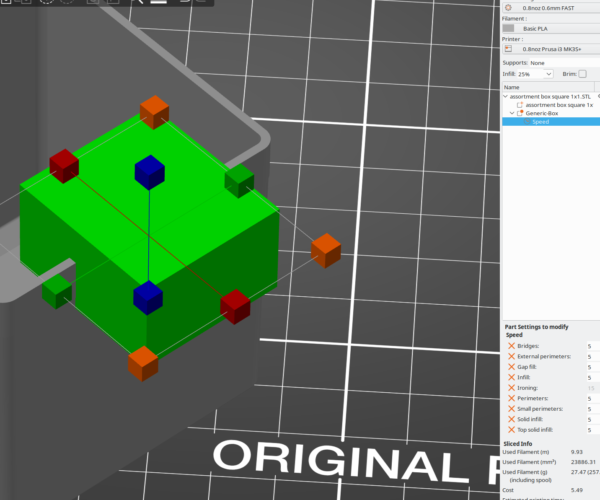

So i decided to try slowing just that one part down with a modifier box

But it did a weird thing with the slice

What's going on here? all the shape should do is change the speed, so I'm not sure why it now isolates that entire shape... very confused now... is this because i rotated it to a 45 degree angle first? (also did the same for the modifier box)

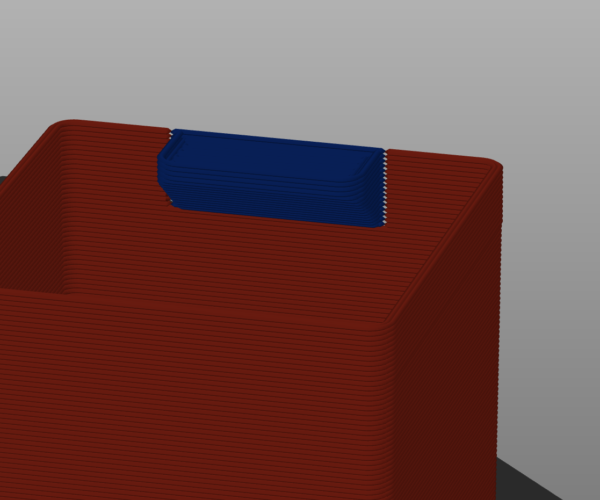

I could have caught this weirdness by looking at the sliced output before I hit print but not this time... here's the beautiful weird box that came out!

Another problem pops up when I fix the first one 😀

That what modifiers do. They always have. They in effect split the model into separate areas for slicing so you get the effect you have observed where a modifier interacts with perimeters.

There have been several GitHub issues raised but from what I can gather it’s fundamental to the way they work at the moment and will require a non trivial amount of effort to redo.

Here is the bottom of the latest failed print, it looks a bit loose in the middle, using the textured plate, but maybe that’s a bad idea with PLA

PLA can be tricky with a textured plate

the gluestick might have made things worse though… will try the clean side next.

But you shouldn't need gluestick - if you have one, try this print with a smooth sheet.

and lower z-level adjustment too

Definitely. The individual strands of laid filament should be almost indistiguishable, fused together into a sheet, especially so with a textured bed.

If the first layer is sound it takes a much harder knock to dislodge.

Can you open your enclosure to aid cooling? Or direct a room fan into the open door?

Really fast cooling may reduce movement at the expense of building more overall stress - but if you can produce a complete part you can release the pent up tension by annealing.

Cheerio,

@julian-5

would you care to post a Zipped up .3mf project file? I'll take a look if you do and see if I can assist.

Regards

Swiss_Cheese

The Filament Whisperer

RE: where i got the model from

Sadly I closed that specific prusa project, but the files are the boxes from this guy's video/shop https://www.alch.shop/shop/p/1x1

@julian-5

No worries, I was going to show you how to fix the print speed issue using modifiers.

Thanks for letting us know, maybe next time.

Regards

Swiss_Cheese

The Filament Whisperer