Volunteer to slice a multi-material print to check an issue?

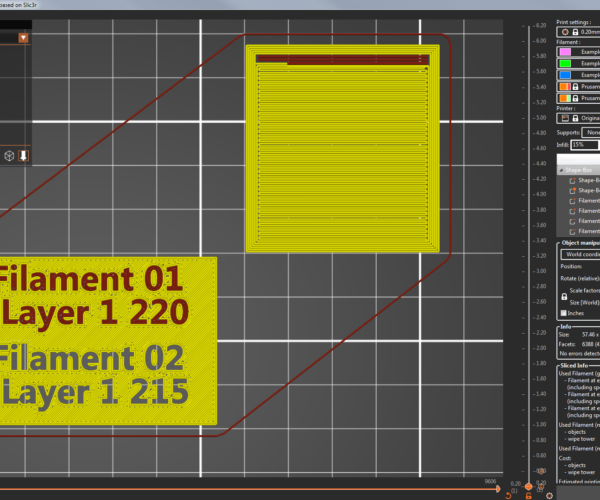

I'm hoping someone can check my project file and/or just slice the STEP file to see if a temperature issue persists. The part has two components. One I sliced with a filament that was 220/215 (1st layer/other layers) and the second at 215/210.

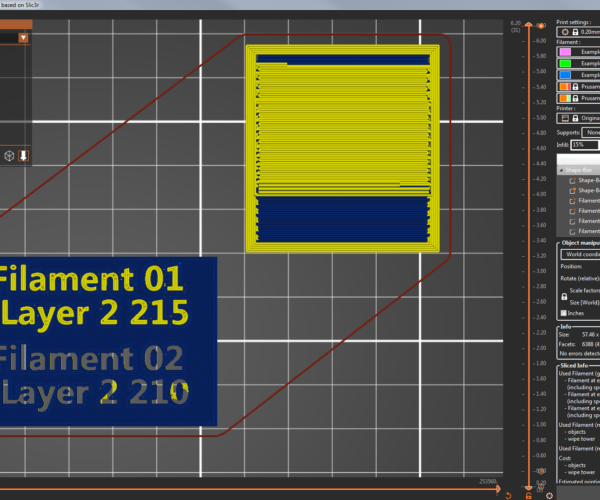

On the second layer it seems there should be an M104 S215 line in the gcode to print the 1st filament correctly. But it is missing and so it prints at 210.

I would love to find a solution to this but no previous responses here or to my Github bug report so hoping someone can confirm that the temp change is missing when it should be in the gcode.

Attaching a zipped project file and a zipped file of just the STEP file.

Thank you in advance.

RE: Volunteer to slice a multi-material print to check an issue?

STEP file

RE: Volunteer to slice a multi-material print to check an issue?

I sliced the first file using Prusa Slicer 2.6.0 Alpha5

And the print starts at 220C, then drops to 215C at layer 2

Temperature Issues_0.2mm_PLA_MK3SMMU2S_16m

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Volunteer to slice a multi-material print to check an issue?

Hi Joan,

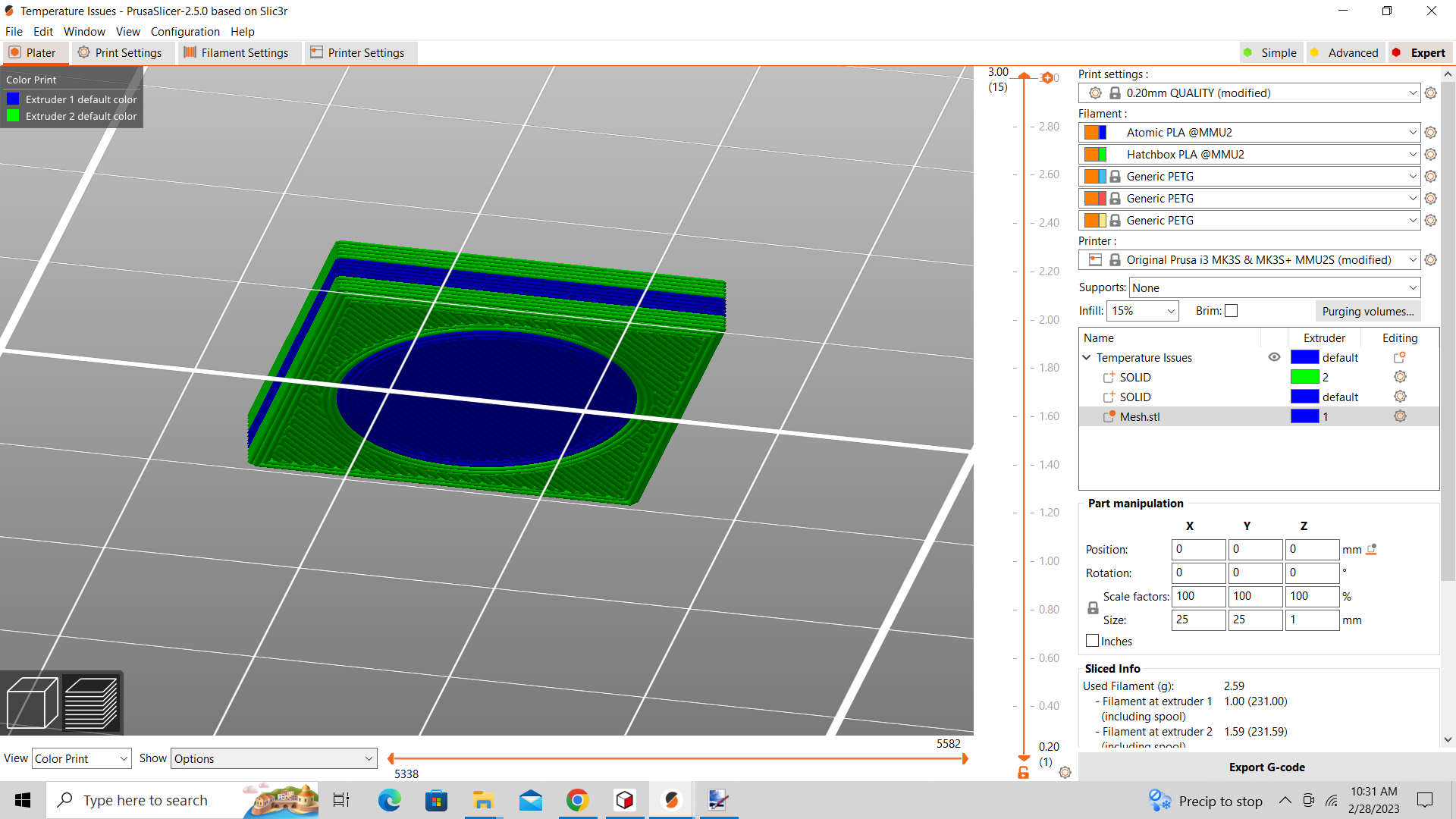

Thank you for taking the time to slice the project. Did you slice for an MMU unit?

If you were looking at the project file (if I saved it correctly) there should be two components to the part, a small round disc inside a square. So the part should have two different temperatures on Layer 1. 220 for filament 1 and 215 for filament 2. On layer 2 they should then be 210 for filament 2 and 215 for filament 1 (printing in that order). The issue has been that on layer 2 filament 1 is printing at the wrong temp. Missing an M104 S215 line in the gCode.

If there is only one temperature for layer 1 and one for layer 2 that would be a further problem. There should be two different temperatures for each of those layers depending on the component being printed.

On the other hand I've been using 2.5.0 and if the whole thing were fixed in 2.6.0 that would be fabulous!

RE: Volunteer to slice a multi-material print to check an issue?

Sorry, tried to edit the post but time had expired of course. I realized that the gCode you attached was not my gCode but yours.

So, there appears to be a further error. Your gCode, just as you said, prints all of Layer 1 at 220 and all of Layer 2 at 215. There should be two different temps being used on both layer 1 and layer 2. When I slice it I get Layer 1 correctly using 2 temps, but Layer 2 incorrectly using only 1 temp.

Any thoughts?

RE: Volunteer to slice a multi-material print to check an issue?

try this

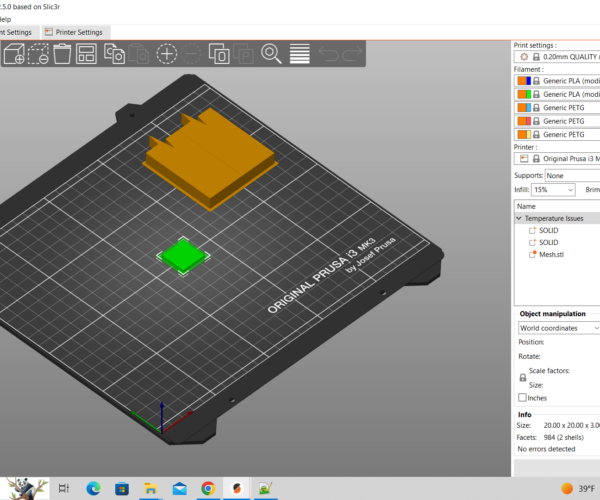

I think the issue is that you are using Generic PLA (Modified) Twice... and I believe that confuses the slicer as it doesn't know there are two sets of temperatures

If you set up two different PLA Profiles you might find that the actions are more to your liking.

Unfortunately I am not sure which part needs to be which temperature, so I allocated them randomly.

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Volunteer to slice a multi-material print to check an issue?

Hey Joan,

So this is interesting, I actually did NOT use two Generic PLA filament presets. I have separate presets for Atomic and for Hatchbox which are the ones I used. That isn't material but it IS curious that they do not show up in the project file when you open it. Below is a screenshot from my original post where you can see the colors and the preset names. I just reopened the project file and they are still there. They might have originated from Generic PLA, but all presets originate from somewhere correct? Is there some other way to create presets that I am missing?

The allocation of which temps are on which part doesn't matter that I'm aware of, same problem will persist.

So the problem could be with the way I create presets?

Were you able to assign two different presets with different temperatures to the two objects and have them print correctly over the first two layers?

RE: Volunteer to slice a multi-material print to check an issue?

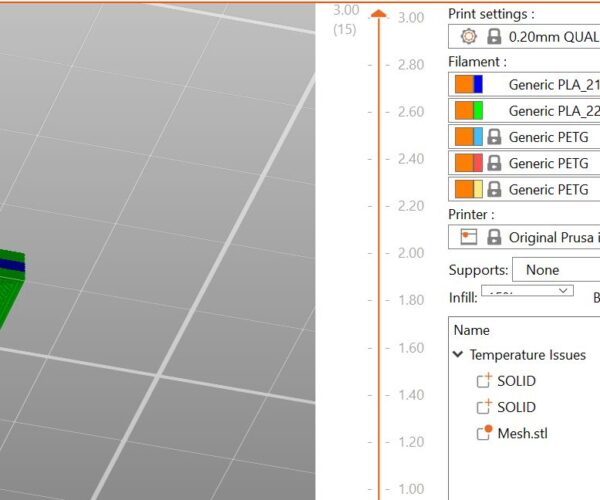

So when I open your modified project file it too shows the two filaments as "Generic PLA (modified)" - see attached screenshot. Is this expected or did you name them differently?

I can see in the gCode that you do seem to have the right M104s in the right places (missed one of them the first time I looked). The order of the ones you used was backwards from what I had (I had the 220 / 215 blue circle printing first) but I don't think that is what makes the difference.

I'm still somewhat at a loss as to why my slice doesn't work. When you create a new preset do you need to always start with a Prusa preset? I will often start from one of my own revised presets. Hatchbox to Atomic etc.

RE: Volunteer to slice a multi-material print to check an issue?

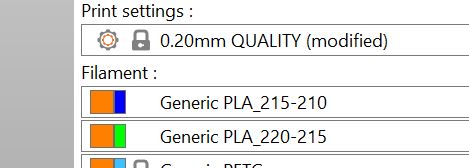

thats odd, when I open the file it shows two different names

Both are based on Generic PLA, they are two different profiles

One has first layer at 215 and Remaining layers at 210C

the other has first layer 220C, remaining layers 215C

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Volunteer to slice a multi-material print to check an issue?

Yep, and same with me and my original Project file. I have two different presets, one named Atomic (at 220 / 215) which was the blue and one named Hatchbox (215 / 210) which was the green.

So PS must not retain the filament preset names in a Project file, just the original source (Generic PLA) and the settings (or some settings in my case since the temps didn't work).

RE:

@rickm-3

As you are discovering filament profiles aren't transferring properly. Ps keeps part and drops part of the filament profile. This isn't new, it's been going on for a few versions with custom profiles.

I have a working example if you didn't get this working for you already. If you did no worries.

Assuming my post ever makes it out of moderation.

RE: Volunteer to slice a multi-material print to check an issue?

please try this version

Temperature Issue revised JT V6

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Volunteer to slice a multi-material print to check an issue?

Pretty interesting. So opened the project file:

The 1st filament still shows as "Generic PLA (modified)". If I go into Filament Settings it looks like it was my Hatchbox preset (same cost, extrusion multiplier, etc), so I'm guessing you used one of the filaments from my original project file? It will not let me select another filament (in Filament Settings) unless I choose to save or not save the Generic PLA (modified).

The 2nd filament shows as "Prusament PLA" now, which I'm guessing you switched to?

When I just slice your project file it again appears that all the filament temperatures are switching correctly via M104. Different from my experience but certainly encouraging.

Interestingly, because Prusament PLA has different bed temp (60) from my preset (70) the bed temps could be changing too. Not sure what the right answer would be for bed temps changing... I think I would prefer it picks the highest temp for a layer and leaves it there which it looks like it may be doing, whether by intent or algorithm I'm not sure.

So something about your setup or the way you select filaments seems to result in correct gCode on temps and something I do results in bad gCode... not at all surprised it's me, just hoping to get it sussed!! lol

RE: Volunteer to slice a multi-material print to check an issue?

if I modified a generic PLA profile for the second temperature, the slicer renamed it to Generic pla

I renamed the second filament to be a prusament profile, prusa still renamed it, but this time it renamed it to prusament...

so the first two filaments had different names... and could produce different temperatures.

have you considered voicing your concerns on the Prusa GitHub pages for Prusa Slicer?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Volunteer to slice a multi-material print to check an issue?

Hey Joan,

Yes I joined GitHub and submitted a bug report (#9946) two weeks ago but no reply as of yet.

I greatly appreciate you looking into this and I AM encouraged that something you do makes the temps work. At least shows that it is possible and I can try different things until I get it working.

Cheers!

RE: Volunteer to slice a multi-material print to check an issue?

@rd

Thank you for the response. The filament transfer issue came up when Joan and I were trading Project files back and forth. I am not sure if it is related to my original issue of missing M104 lines during Tool Changes or not. It would seem possible that the same issue resulting in bad transfers also causes PS to miss putting in an M104 line?

Joan got good results on gCode so it must be my filament presets are off somehow or the other. I would certainly look at your working example to see if it helps me out. Or if you have any other suggestions.

Thank you much!

RE: Volunteer to slice a multi-material print to check an issue?

@rickm-3

The Filament profile issue is an old one, and I don't think that's the main problem, it's just making it more difficult to pass the information you need. I'm going to be using 2.6 alpha 5 for the example file, and I'll try to walk you through the filament profiles. As well I set up the example as best I could to make it easier to follow.

The very first thing your going to want to do (before you even open the example file), if you haven't already, is go to "Preferences" [Ctrl+ P] select the GUI Tab, and look for "Order object volumes by types:" if it's ticked, Un-tick it. Then select Ok and go back to the UI.

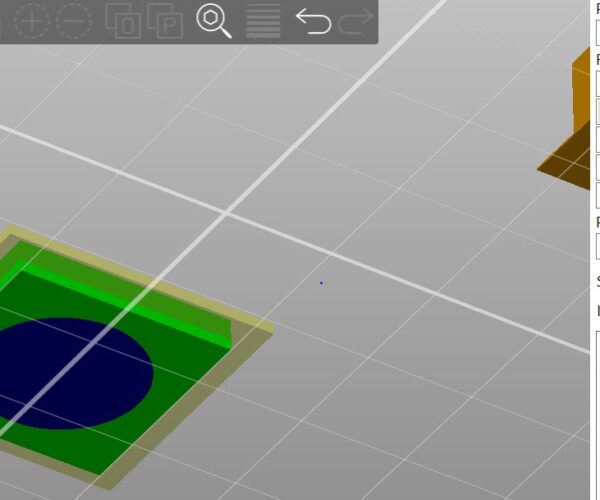

Open the project file I sent you with PS 2.6 alpha 5. Before doing anything else go to the "Filaments Settings Tab" and verify that you have three filament profiles matching the 01-03 Example Filament PLA @MMU2 profiles displayed in the attached image of the first layer, make sure that the names match exactly, and if they don't, then create them named just as I have them, and save them. I only changed the nozzle temps to match those you requested, and I listed the temps in the names to avoid confusion. You may notice that 03 has the same profile as 02 that's necessary so be sure they all exist as shown. After the three profiles are verified or created, be sure they are add to the appropriate filament slots in the Sidebar.

(Click for full image)

Once all that's out of the way Slice the project, select Temperature from the drop down in the legend, and verify that the first layer temps are correct.

"Filament 01 Layer 1 220" is a part that I assigned the default extruder.

"Filament 02 Layer 1 215" is a part, it's the "Shape-Box" that I assigned extruder 2. I used negative volumes to produce the letters in this case, but that has no barring on the temps, it was just for the sake of communication.

Next, go to layer 2 (AKA Other layers:) and verify that the temperatures correspond to those shown in the text.

(Click for full image)

From here I applied a Shape or volume based modifier to the area above the second layer, and I assigned it extuder 3. This modifier allows us to apply the "Other layers:" settings matching our Filament 02 profile to the remainder of the Shape-Box. If we were to try and use the Filament 02 profile however the temperatures would default back in this case to the first layer temperatures on the second layer.

I would like to draw your attention to the vertical slider and Note that layer (1) 0.2 and layer 2 (0.4) have custom G-code added very simple but necessary for the temp changes on layer 2. It's also worth note that this technique works differently in different versions of slicer, meaning it still works but you have to put the information in different areas and change it slightly.

I still do all of my main work in 2.4 as I found myself very dissatisfied with the problems and loss of control in 2.5 and now 2.6, I won't hold my breath that they'll make it better but I can hope. I did this in 2.6 because it was the closest thing I had installed to 2.5 to help you with, it might work the same in 2.5 I didn't test it to see.

I would encourage you to play around with the settings in the example file to further your understanding. There are other ways to do this I just find this way amenable.

Good Luck

RE: Volunteer to slice a multi-material print to check an issue?

@rd

Thank you very much for taking the time to do this. I will go through it this weekend and try out what you have done.

This has been one of those issues that is annoying but always gets put on the back burner. Hopefully this gets me moving in the right direction.

Thanks again!