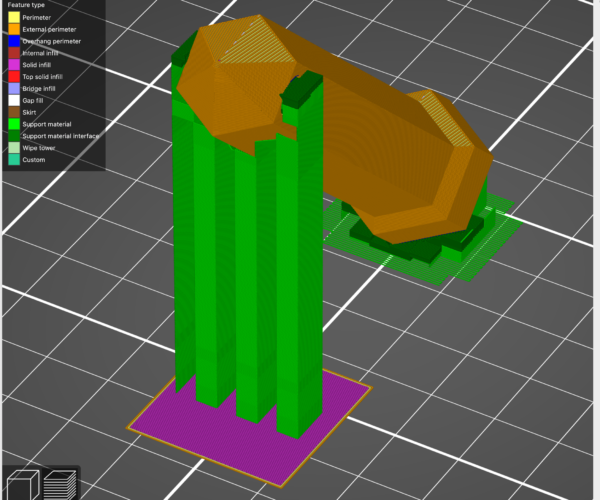

Supports on the build plate should have a solid bottom interface for better adhesion

Is there a solution to this problem? For instance, does anyone know of a gcode workaround I can use?

For reference I would like to rid this problem, described here: https://github.com/prusa3d/PrusaSlicer/issues/1165

If this has already been discussed and I failed to find it through endless searching, please point me to the correct link. TIA

RE: Supports on the build plate should have a solid bottom interface for better adhesion

I can only tell you that the default dense interface layers work very well provided your print surface is properly cleaned and Live-Z calibrated. You can adjust the density of the support layers.

Zip and upload your STL or (better) 3MF project file for more suggestions.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Supports on the build plate should have a solid bottom interface for better adhesion

Edit: My memory was bad. The interface layer density is only for the bits directly supporting the part. I may have been thinking of Cura.

It's a reasonable feature to implement, but you should be able to get decent adhesion in the meantime.

Does creating a modifier block help? It won't be tailored to your part, but you can get a solid layer under key bits of support. I've used this approach for creating mouse ears to tack down sharp corners.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Supports on the build plate should have a solid bottom interface for better adhesion

Thank you for the suggestion. Creating a modifier block is brilliant, but cumbersome and laborious on complex geometry (although it may work on simple designs - idk, haven't tried it yet). I'll give it a go today and see what I can do. Thank you again for your creative suggestion.