"Support blocker" doesn't affect supports from "Support enforcer"

I'm adding support to a delicate project, where I have to use support enforcers on some areas, but with the shape of the available "support enforcers", it'd add support to one spot, where there should be no support. I've added a "support blocker" to that section, but it gets ignored. Is there some way to give blockers/enforcers precedence, to let the slicer know, which one it should apply last?

hw: PRUSA MINI+, FW 4.3.3 & Cr-10s w/ BLTouch, Ezboard, Hemerasw: PrusaSlicer 2.4, Windows 11

RE: "Support blocker" doesn't affect supports from "Support enforcer"

Your best bet is to use paint-on supports. Ever since they started adding that feature I pretty much stopped using the shape-based supports.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: "Support blocker" doesn't affect supports from "Support enforcer"

@teachingthedetails

There are two things I can think of to do in this situation, if I'm understanding your needs correctly. 🤔

(1). In your 3D program make custom shapes that meet your support needs as "support enforcers" and import them with the model and simply change their type from Part to "support enforcer" in slicer.

I have written page long posts about this and so has Neophyl, and I can't for the life of me find one right now. But I'll say it again support blockers only work to block supports on specified areas of the model, not the build surface, and that leads me to suggestion number two.

(2). If your able to use PrusaSlicer2.4.0 or higher, then I will suggest, not only custom built support enforcers, but also setting your supports to Snug style, so far in my experience the Sung setting has been working out very well, (the supports go where you put them) with only a few bugs that I was able to develop workarounds for.

Furthermore, if you post a Zipped up .3mf project file exported from PrusaSlicer, and I'll take a look and see if I can help. The .3mf file should be setup as you would when trying to print the part and will allow us to see all the settings as they pertain to the model in your project.

Note if you do not Zip the file the forum server will not allow it to be posted.

Regards

Swiss_Cheese

The Filament Whisperer

RE: "Support blocker" doesn't affect supports from "Support enforcer"

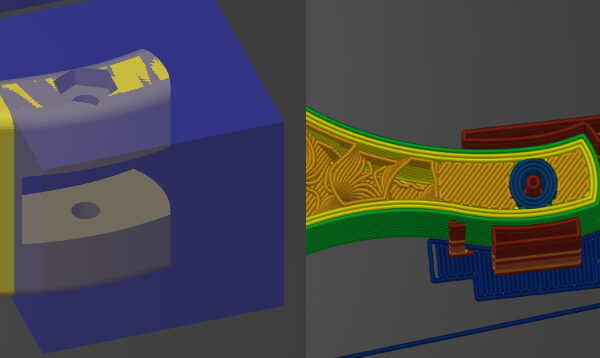

My apologies, really should have included the image in the first post.

Essentially, I'm trying to print this hinge, where the upper part requires support, but with a 0.6mm nozzle, having support inside the hole makes it near impossible to remove.

hw: PRUSA MINI+, FW 4.3.3 & Cr-10s w/ BLTouch, Ezboard, Hemerasw: PrusaSlicer 2.4, Windows 11

RE: "Support blocker" doesn't affect supports from "Support enforcer"

As I said before, I'd paint on supports to the top of that hinge and leave the hole out.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

Edit-timer ran out.

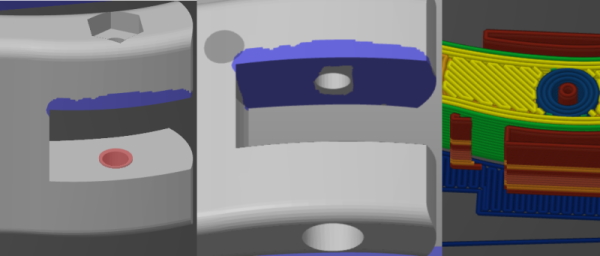

When using Paint-on Support, it also ignores the support blocker, as shown below.

@Swiss-Cheese

I've tested the "snug" supports, but with my 0.6mm CHT nozzle, snug makes it hard to remove the supports properly. With the "grid" support, it's much easier to break off the support, since they extend beyond the actual print.

hw: PRUSA MINI+, FW 4.3.3 & Cr-10s w/ BLTouch, Ezboard, Hemerasw: PrusaSlicer 2.4, Windows 11

RE: "Support blocker" doesn't affect supports from "Support enforcer"

Okay, let's see the zipped 3mf file. This should work.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: "Support blocker" doesn't affect supports from "Support enforcer"

Attached is the .3mf file with the settings how I printed it.

hw: PRUSA MINI+, FW 4.3.3 & Cr-10s w/ BLTouch, Ezboard, Hemerasw: PrusaSlicer 2.4, Windows 11

RE: "Support blocker" doesn't affect supports from "Support enforcer"

Ok, support blockers just dont work like that.

I cant find my previous post either Swiss so here a recap.

All enforcers and blockers do is define areas on THE MODEL that do and do not need supports. That's it, doesn't matter if its defined by a modifier or painted on. Same thing.

Once those areas are defined then the algorithm takes over. It will then proceed to create supports influenced by your settings (x/y separation, z distance, spacing etc) to support those areas that you have defined as needing support.

It will then generate that support downwards regardless. The only setting that will stop it is support on build plate only, in which case it shouldn't put any on the model (but does sometimes anyway with the old non snug type).

Having a blocker below an area where above you say needs support will do nothing. The area above needs support, end of as far as the software is concerned. A blocker isn't a keep out area or anything like that. It's one reason I very rarely use a blocker, might was well be more careful designating areas to enforce which is much easier with the paint on support method.

I've got my cr10s fitted with a 0.6 nozzle too and if I was printing it I would do it like the attached project. Although I'd use cubic infill rather than gyroid, personal preference. The supports as configured would release cleanly for me with PLA. The only bit I would have to scrape off would be the lower support interfacing probably. The bits inside the holes would just poke out. If those are sticking for you with that sort of clearance then I'd be checking my printer for sloppy belts or turning down the support speed as 100mm is rather on the high side. ymmv naturally.

RE: "Support blocker" doesn't affect supports from "Support enforcer"

With paint-on support, you've still got to be careful with where you place your support. In the attached 3mf I painted around the top hole and I end up without any supports inside the holes. There's probably better ways but that's the result of 10 minutes trying.

Also, any particular reason you're printing in that orientation and not flat on what I'd consider the bottom part of the hinge? You wouldn't need any supports at all. The holes should come out okay, or maybe require a bit of drilling out. Of course there could be static reason for printing it in the orientation you've chosen.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: "Support blocker" doesn't affect supports from "Support enforcer"

@teachingthedetails

looks like you found the help you needed.

In the case of Fuchsr's file, you may also want to set "First layer expansion" to zero, that will keep everything clean.

Good Luck

Swiss_Cheese

The Filament Whisperer

RE: "Support blocker" doesn't affect supports from "Support enforcer"

Thank you everyone. This really healps to understand supports better.

hw: PRUSA MINI+, FW 4.3.3 & Cr-10s w/ BLTouch, Ezboard, Hemerasw: PrusaSlicer 2.4, Windows 11

RE: "Support blocker" doesn't affect supports from "Support enforcer"

Also, any particular reason you're printing in that orientation and not flat on what I'd consider the bottom part of the hinge? You wouldn't need any supports at all. The holes should come out okay, or maybe require a bit of drilling out. Of course there could be static reason for printing it in the orientation you've chosen.

For a hinge you will get better strength using Teachingthedetails orientation. If you printed it upright the likelihood is it will break along the layer lines right at the bolt level. With it 'laying flat' the layers have way more surface area and the bolt itself will be clamping the layers together. All combines to make it much stronger.