Slicing thin wall parts (airfoil)

Hi, I would like to slice and print an airfoil with a single perimeter wall, including a reinforcing rib. In Fusion 360, I designed the airfoil as a 0.4 mm thick shell and exported it as STL. In PrusaSlicer, I had to enable "Detect thin walls" in Print / Layers and perimeters, otherwise the thin shell would be ignored.

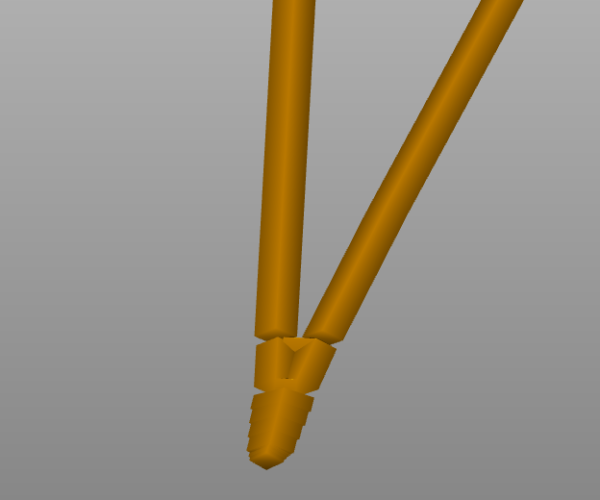

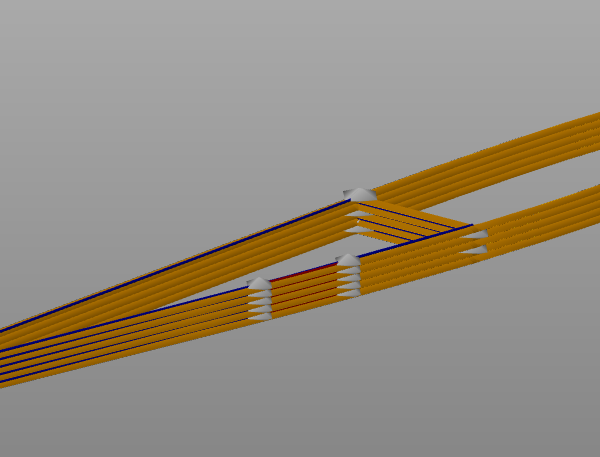

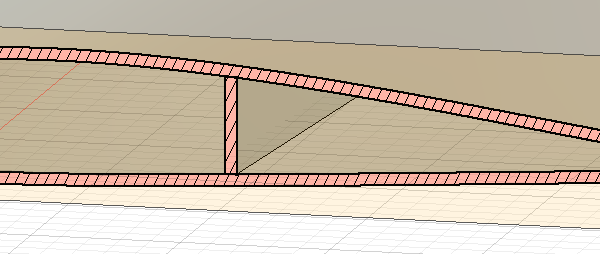

However, I am not happy with the slicer results. There are many retractions and travels that are not necessary (see the attached image). Each layer should be printed as a single closed curve (the airfoil profile) followed by a line for the rib. Ideally, the seam should be placed either at the leading edge or the trailing edge (i.e., the points with the highest curvature). Also, the trailing edge is broken into several segments.

I tried modifying many parameters ("Seam position", "Detect thin walls", extrusion widths) and altering the geometry (chamfer/fillet of the trailing edge, making the shell walls slightly thicker than 0.4 mm, ...), but none of this helped. I also tried to export the airfoil as a surface (no thickness), but the slicer added infill inside the airfoil as if it was filled; and when I set the infill to zero, the rib inside ignored.

May I please ask if there are any more parameters that I could tweak to obtain better results? Or should I change my geometry?

I attach the PrusaSlicer project, the STL file and the Fusion design for reference. I could not upload the files to the forum, so here they are on Google Drive:

https://drive.google.com/drive/folders/14ZOhUaP4ZEDxjLyYID1jsWA77Pxe86jV?usp=sharing

RE: Slicing thin wall parts (airfoil)

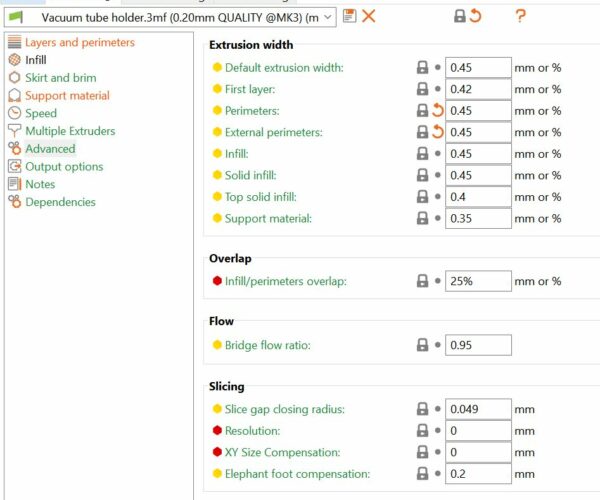

I think you are overlooking the settings for extrusion width, in Prusa Slicer,

it would probably be best to remodel the skins to be 0.45mm thick

as a short term alternatively you could try increasing the XY Size Compensation a little

Turn the trailing edge to the rear of the build plate and set the seam position to 'Rear'

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Slicing thin wall parts (airfoil)

@joantabb Hi Joan, thank you very much for your response! I did try modifying the extrusion width (reducing all extrusion width parameters to 0.4 mm) and making the skins in the model thicker (up to 50 %), and I also used the "Rear" value for the "Seam position" parameter, but none of this helped. (Note that the main issue with the seams is that there are too many of them.)

RE: Slicing thin wall parts (airfoil)

To get rid of all seams, the model could be printed in vase mode, but then you will loose the inside rib. Maybe the rib could be a separate model glued in later.

As joantabb suggest the wall is to thin for default 0.4 mm nozzle parameters. The model can be printed if:

- Turn off thin wall detection

- First layer width = 0.39 mm

- External perimeters = 0.39 mm

but that would not solve the problem with seams.

Have a look at my models on Printables.com 😉

RE: Slicing thin wall parts (airfoil)

@area51 Thank you for your suggestions! Unfortunately, the inner rib is very important and must be printed with the outer surface of the airfoil, so the vase mode is not applicable here. I tried the combination of parameters that you suggested and it worked quite well, but when I changed the model slightly, it broke again.

I believe that these issues appear because PrusaSlicer always treats the model as a volume, while I would like it to treat it as a surface, which should be traced with a thin wall at each layer. I analyzed the STL files for the wings of the 3D printed airplanes from Eclipson ( https://www.eclipson-airplanes.com/ ), which are sliced very well by PrusaSlicer, and found that the wing is represented as a single volume and the rib is in fact a hole in this volume.

In the end, I found that Cura has a setting ("Surface Mode") to treat the STL file as a set of surfaces instead of a volume, so I decided to model the parts as surfaces and slice them using Cura.

RE: Slicing thin wall parts (airfoil)

If you are going to pass these files on to other folk, please add information to describe what slicer and what settings are best for reproducing them

otherwise there will be endless complaints that different slicers will not slice them properly.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Slicing thin wall parts (airfoil)

@honzasp it good that you found a solution and thanks for the feedback. I was not aware of the surface mode in Cura.

Have a look at my models on Printables.com 😉