Seams Issue with Arachne

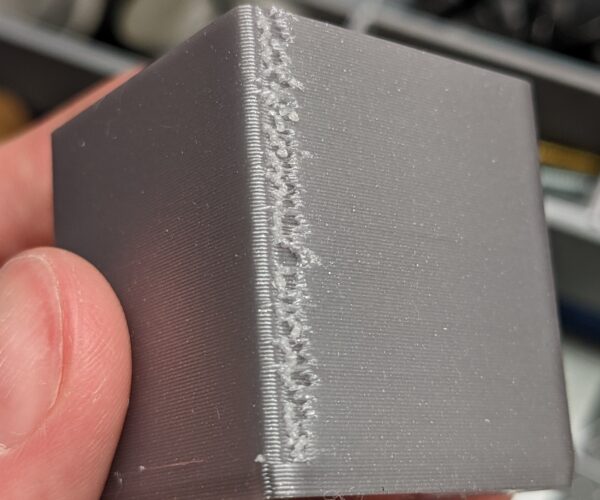

The boogered surface along this corner is a seam that was sliced using the new Arachne setting (PrusaSlicer 2.5.0). Switching to the Classic setting though, all else equal, instead of Arachne produces a flawless print. The bottom 11 layers or so is solid but otherwise this print is a hollow cube with a wall thickness of two perimeters using the 0.3mm QUALITY setting with a 0.6mm nozzle and 0.65mm extrusion width. What could possibly be happening here? I've attached the project file. Printer is an MK3S.

RE: Seams Issue with Arachne

No attached project. You did remember to zip it up before attaching ? The forum has very limited allowed file types and if there's something it doesn't like it simply wont attach it. Without any warnings that it didn't.

RE: Seams Issue with Arachne

Attached zipped PrusaSlicer Project file

RE:

Just one example of (too many) issues with the Arachne algorithm. When it works, it works great. But too many times I've seen suboptimal results. In particular with the seam algorithm, which is as bad as it's always been.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Seams Issue with Arachne

I have to agree about the Arachne, it works ok with some things but not most, first thing I do if using 2.5 is switch it to classic, but that's just annoying. As previously stated and no matter what perimeter gen you use the seams in 2.5 are not good. I had good experiences with seams in 2.4, but I can't get a seam in 2.5 to do anything I want it to, they just refuse to do what I need, and a straight line? give it up.

How does prusa say it on github? you can get a straight seam line with certain models. what do you want a straight line for anyway? that was sarcasm.

RE: Seams Issue with Arachne

How could Arachne possibly be the default when it's so unreliable?

RE: Seams Issue with Arachne

Out of curiosity I printed your project. I didn't have a 0.6mm nozzle fitted so I had to change it to my normal 0.4 printer config but the actual print profile was more like the 0.3 draft. It printed out without any issues related to the seams.

Now I am concerned about the artefacts at regular intervals in the z axis so I will be trying a classic slicing engine to see if that makes any difference (if not then I guess I need to check out some other stuff on the printer like my z rods) but at least with a 0.4 nozzle there doesn't seem to be a seam problem with this model..

RE:

Thanks. I did also notice some z artifacts on my print, which can't be seen so easily in the picture b/of lighting. I'll try printing it again with the most default settings of the QUALITY profile and see what happens.

RE: Seams Issue with Arachne

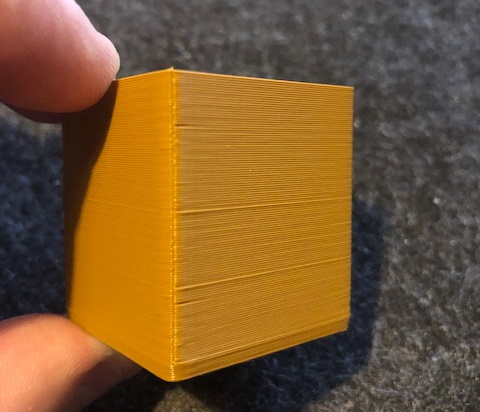

I did print another one with the only change being to classic and the z artefacts went away.

I do agree that the choice of making Arachne the new default seems just a tad premature. I don't think it really is the next 'big thing' but they do seem to like the shiny new toys.

While the wall thicknesses are better with the Arachne engine the artefacts you can see just ruin any gains.

It has its place like any tool but I'll be sticking to classic for most of my prints I think. For those who have the experience to adjust the extrusion widths for classic it is giving better results. You get the proper wall thicknesses and the part looks better.

Who knows over time they may succeed in tweaking it or maybe the settings they have as defaults for arachne are just not that optimal and it will get better, it just isn't there yet.

RE:

damn ran out of edit time. With arachne its mostly doing the detract right on the seam and then proceeding to print the external perimeter first. So most of the retractions are on the inside wall. I suspect with the 0.6 nozzle its not fully priming it so theres missing material before it starts to print properly. Maybe adjust your detract settings might help ? Also just try unticking retract on layer change.

Occasionally the retraction is done on the outside wall instead of the inside. I'm pretty sure thats why there are z aretfacts, on those layers its starting with the inner perimeter and then doing the outer. Bet thats forcing that layer outwards slightly.

With classic its always doing the inner wall perimeter first and then the outer wall, the retractions are all on the same faces so its more even as its always printing in the same way each time.

RE:

Print just finished with 0.6mm nozzle QUALITY profile and all defaults except for removing brim. Looks much better than the original, although the seam has more "texture", i.e. it's not as smooth, than the Classic setting. All along the seam are very tiny filament blobs, some bigger on certain layers than others, and the z artifact lines line up with the bigger ones. I'll now re-print from the original PrusaSlicer project to make sure the issue still persists, then I'll start removing each setting one-by-one until the seam prints correctly. Thinking of removing "Avoid crossing perimeters" and "Detect thin walls" first.

RE: Seams Issue with Arachne

"Detect thin walls" is usually unnecessary and/or can cause issues.

I found 0.6 (and 0.8) seams to be in general more pronounced than 0.4 mm and vary between brands (using same settings).

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE:

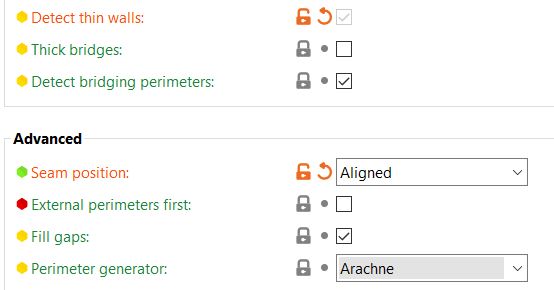

But the seam looks as smooth as can be on the Classic setting, so it's not a nozzle or filament issue. I just noticed that even though thin walls was checked, it's greyed out when Arachne is selected. I guess this means that it's always disabled by Arachne.

RE: Seams Issue with Arachne

Confirmed, Prusa docs say this about the thin walls setting: "This feature is automatically disables, if the Arachne perimeter generator is active, as it already automatically adjusts for thin walls."

RE: Seams Issue with Arachne

Thanks for this post - it seems I encountered the same issue.

I recently switched to a 0.6mm nozzle and started printing a ton of Gridfinity boxes. All of course with very thin, one perimeter walls.

I am doing some more testing to see if classic mode instead of arachne solves the issue. It currently is my best clue because otherwise and in the past i had "seamless" seams. Pun intended. ^^

RE:

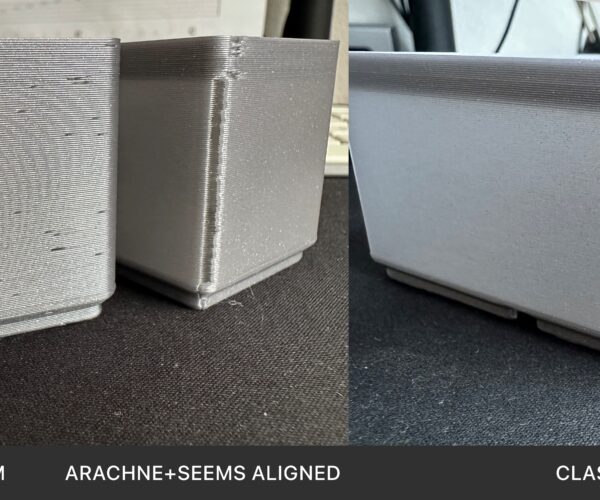

So I printed an new Gridfinity box overnight and the only thing I changed from the default "Prusament PLA" profile was "arachne to classic mode" and "detect thin walls".

I am using a 0.6mm nozzle, Prusament PLA (galaxy silver) and Prusa Slicer 2.5.2:

It is baffling to me that arachne is now the default setting in prusa slicer ...yet this issue exists?!? Doing some more testing to verify the results ...

RE: Seams Issue with Arachne

Ok so I printed a follow up with more boxes. "Classic Mode" and "Detect Thin Walls" active.

It is very weird now various boxes show the seam artifacts again. When printing a single object it seems to be better. When printing multiple objects on a build plate most show huge problems with the seems.

No I tend to believe it maybe a general slicing / slicer problem?

RE: Seams Issue with Arachne

I am trying to slice and print the same with Simplify3D 4.1 next ...

RE: Seams Issue with Arachne

I have been experiencing some similar issues with seams. I suspect when you make a long move this causes the seam gap. Did you ever resolve the issue?

RE: Seams Issue with Arachne

No ... I still have that problem. I also found a similar issue at github: