Seam position: Aligned

Good afternoon (o;

The default settings for perimeters is that the seaming position is aligned....

But why does the inner perimeter has then a different starting point than the outer perimeter?

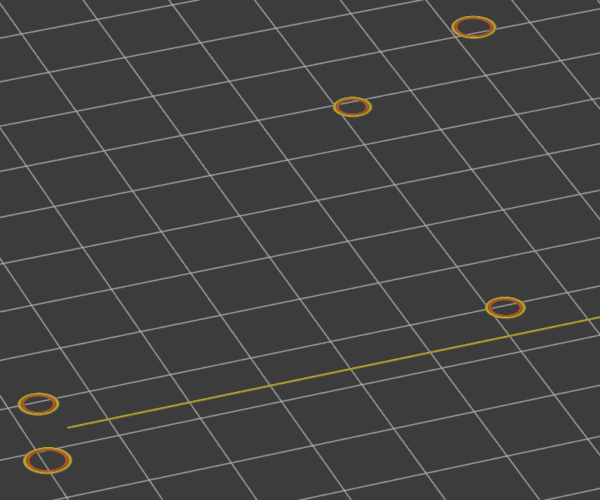

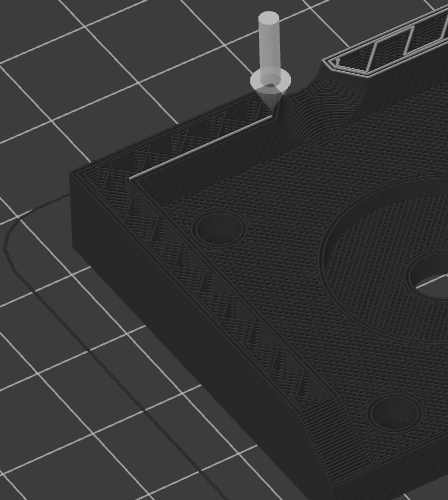

Start of inner perimeter:

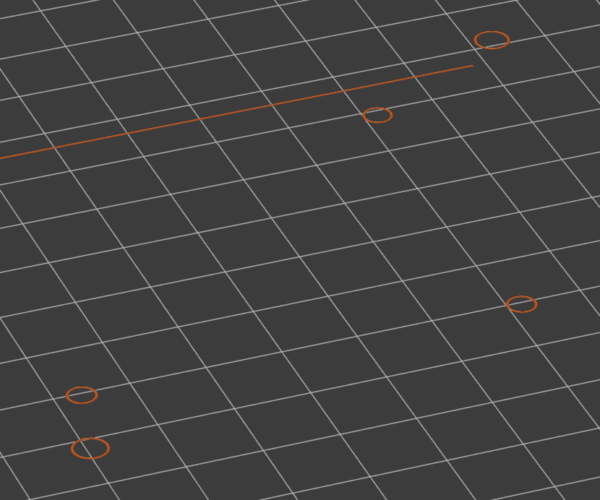

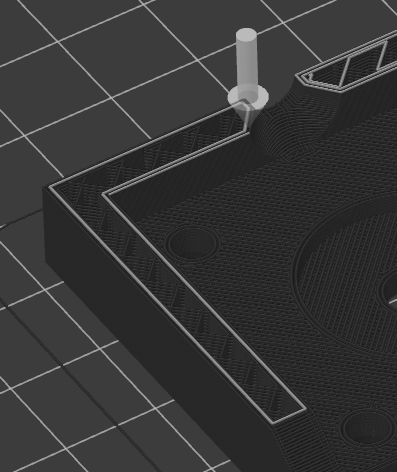

Start of outer perimeter:

So what does the "Aligned" actually mean?

thanks in advance

richard

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

Seam position: Nearest, also inner and outer perimeter have a different start position

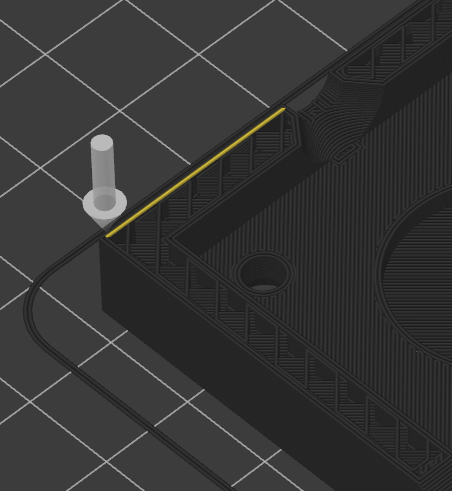

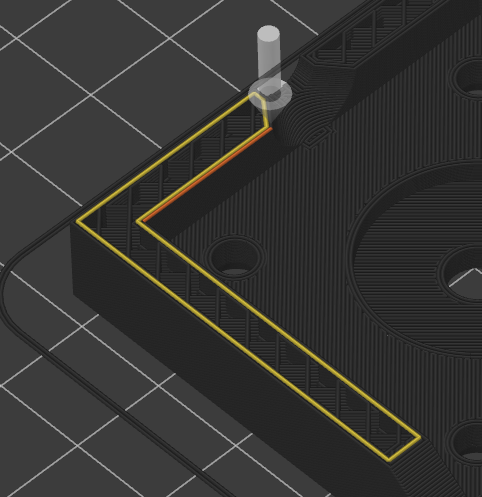

Tried with the benchy now...and also with "Seam position: Nearest" the start position of inner and outer perimeter is different:

Inner perimeter:

Outer perimeter:

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

RE: Seam position: Nearest, also inner and outer perimeter have a different start position

Afternoon (o;

Wonder why nobody else is having this problem which causes defects on the outer wall....

Anyway...filed an issue now on github......so going back to Simplify3D as it handles this always correctly...

https://github.com/prusa3d/PrusaSlicer/issues/6790

Also discovered that when it does for example a square outline and then the solid infill, it starts the infill at the opposite corner instead where the perimeter ended...also something which does S3D correctly....

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

RE: Seam position: Nearest, also inner and outer perimeter have a different start position

Okay...filed an issue with the solid infill problem as well...

https://github.com/prusa3d/PrusaSlicer/issues/6791

Looks like it never will make it through when I see over 1700 issues on github (o;

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

Feature requests

Looks like it never will make it through when I see over 1700 issues on github (o;

Bear in mind the 1700 includes a gazzillion feature requests.

To drum up some support it might be useful to post some pictures that demonstrate the practical impact your finding has and how the way the slicer puts the z seam appears to affect your prints.

To be honest, in all my time printing I never felt the need to even check if inner end outer perimeter started in the same location. PS seems to do a pretty decent job hiding the seam in corners, and models without corners are always a challenge.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Seam position: Nearest, also inner and outer perimeter have a different start position

Sadly I don't have a camera with macro lens to take a good picture...but it is surely visible...

But then again..I am talking about a bug in PS 2.3.3....as Slic3r 1.3.1-dev does it correctly..as does Cura and S3D....

Slic3r start of inner wall:

Slic3r start of outer wall:

So it makes a nice wall without artifacts 😉

The same model with same print settings at the same layer height....

Start of inner wall:

Start of outer wall:

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

Internal pathing decisions are subject to a number of feature settings

[...] Wonder why nobody else is having this problem which causes defects on the outer wall....

If inner seams are causing blemishes on your external walls, that suggests you have other issues. A common problem is to over extrude slightly, which will cause bulging and blemishes at seams and retraction points. Have you calibrated your extrusion multiplier? You cannot completely eliminate the z-seam with current consumer-grade FFF printer, but you can certainly reduce them.

[...] Also discovered that when it does for example a square outline and then the solid infill, it starts the infill at the opposite corner instead where the perimeter ended...also something which does S3D correctly....

A lot of these "problems" are usually related to various other features you can select in the slicer. You'll notice things like selecting do not cross perimeters changes movement quite a bit. PrusaSlicer is going to follow a series of optimization decisions. In the end, unless the internal pathing decisions cause problems with your print finish or times, I don't agree that this is a "problem" even if it is "obviously not efficient". If you have any data demonstrating that it is an actual problem I'm sure the devs will be appreciative.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Internal pathing decisions are subject to a number of feature settings

Seams are not a problem...it is more that the outer wall shows a short "under extrusion" as the extrusion is interrupted when the nozzle moves to another position instead of starting where the inner wall ends...it is more visible when printing ASA for example...

For the infill path decision.....tried with Slic3r as well....and Slic3r starts the solid infill where the perimeter ended....

So for sure there is a difference how both handle the slicing....

Don't get me wrong...I really like Prusa Slicer for its vast possibilities...g-code customization being the best one as S3D is just way behind (and always will be as it is dead since years now ;-). I wouldn't mind to pay for PS if there would be a commercial version...

Nevertheless I use S3D for my Ender-3..which has been a workhorse for years now...and for printing small Nylon parts with a 0.3mm nozzle it is just great (o;

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

Are you getting this problem on a Prusa or Creality printer?

Seams are not a problem...it is more that the outer wall shows a short "under extrusion" as the extrusion is interrupted when the nozzle moves to another position instead of starting where the inner wall ends...it is more visible when printing ASA for example...

Can you post pics and (even better) save your current 3MF project file, zip it up, and attach it to a reply here? It's much easier to help when we can see all of your settings and positioning. What you are describing sounds like a possible problem with retraction settings. Are you getting these problems on an Ender or a Prusa? The reason I ask is that a bowden extruder setup requires different retraction parameters than direct drive.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Are you getting this problem on a Prusa or Creality printer?

Using an Ender-5 Plus printer with Micro Swiss direct drive extruder....also the board has been replaced with a BTT SKR v1.3 and TMC2208 stepper drivers...

Attached the project file of the Y-axis motor holder of my OpenPNP machine...

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

Defect on all prints?

I'll defer to Charles or one of the other Creality owners for specifics on retraction settings. You might want to work on a smaller print to see if you can replicate the problem on a 15-30 minute print just to speed up testing. Do you get the same defect even on a simple larger (e.g., 40x40mm) cube? Linear Advance can be a cause of tearing and inconsistencies on layer changes. Acceleration and jerk setting tuning can also help.

FWIW - Here's an example of how much it's possible to tune the z-seam in PrusaSlicer even on a difficult sphere print. It's far from perfect, but it would sand out easily if I needed to and is easy to hide otherwise:

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Defect on all prints?

Not sure if we're going off-topic now...the original question was why the start point is different for inner/outer walls...though it is not always the case within the same model...depends on the actual geometry at specific layer height....any way...

This artifact caused by under extrusion (caused by nozzle moving to another starting position of outer perimeter) isn't always happening...when start point is the same for inner/outer walls it is fine...

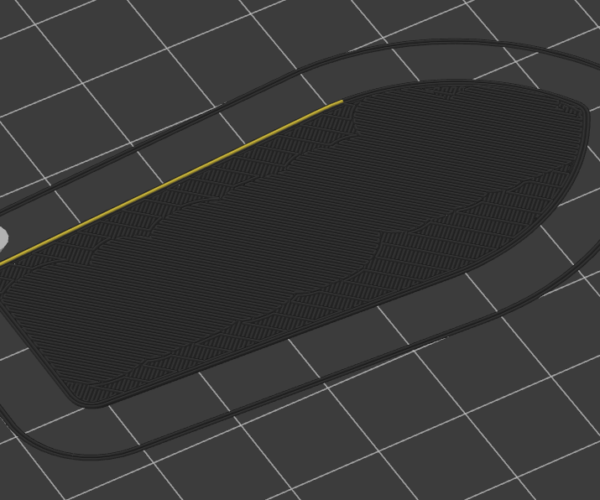

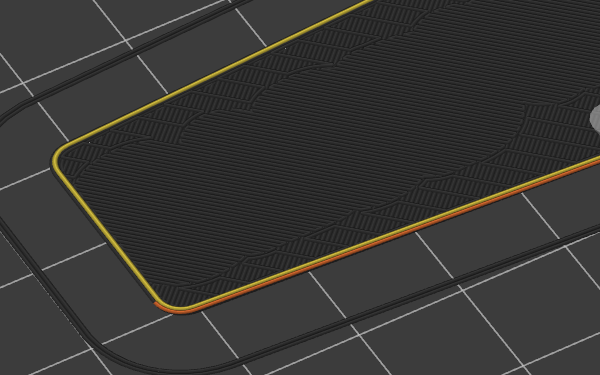

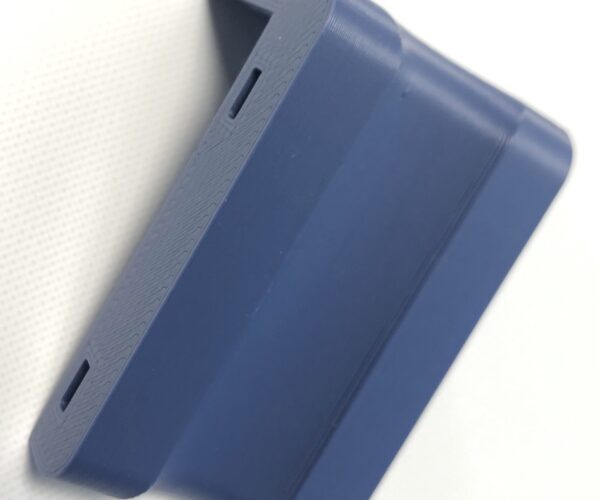

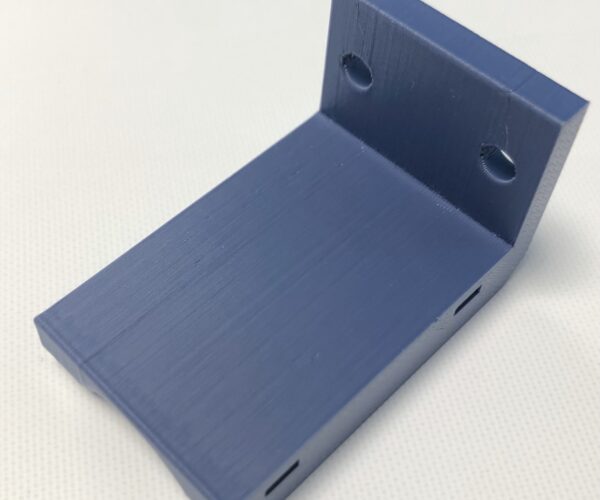

Here pictures of the extruder cable holder for the Ender-5 Plus printed with Extrudr NX2 (a bastard PLA....stick too hard to Buildtak or glass bed....and clogs a Micro Swiss 0.3mm nozzle):

Not perfect...but I'm fine with it (o;

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

Nice prints

Not sure if we're going off-topic now...the original question was why the start point is different for inner/outer walls...though it is not always the case within the same model...depends on the actual geometry at specific layer height....any way...

I pulled up your 3MF, and it looks like selection of infill and other settings will also affect things. It does make sense that varying layer geometry might require moving the seam around. So you're all good on this issue now?

[....] Here pictures of the extruder cable holder for the Ender-5 Plus printed with Extrudr NX2 (a bastard PLA....stick too hard to Buildtak or glass bed....and clogs a Micro Swiss 0.3mm nozzle):

Those look very good, at least from what I can see in the pics. You might experiment with Linear Advance to even out flow to reduce that "dog bone" effect in the left corners on the bottom pic (assuming your printer supports LA). Otherwise, acceleration and jerk settings can help. A very minor issue though.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: Nice prints

Thanks....as mentioned I am very happy with Prusa Slicer as it offers much more than S3D....

I'll leave this starting point issue open on github....and see if a developer comments on it...

Ah LA it is called....always wondered why there is not such an option in PS as I looked for a coasting setting....that's how it is called in S3D....

Hmm...looks like I have to recompile Marlin with this option as well......

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

LA

[...] Ah LA it is called....always wondered why there is not such an option in PS as I looked for a coasting setting....that's how it is called in S3D....

You do need Linear Advance enabled in your firmware. If you do have it, it largely eliminates the need for coasting and other work-arounds. LA plus calibrating my extrusion multiplier have allowed me to minimize most of the retraction and related settings that are work-arounds for flow issues.

Hmm...looks like I have to recompile Marlin with this option as well......

Unfortunately, yes. Well worth it though.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Re: LA

Well re-compiling new firmware is no issue.....do compile firmwares all the time (o;

But definitively have to dig into this material.....are there any docs explaining this in detail?

Would it mean to set up LA just once or per filament type/printer setting?

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

Insert gcode into filament preset

[...] Would it mean to set up LA just once or per filament type/printer setting?

It's pretty basic in PrusaSlicer. You insert an M900 Kxx line into filament custom start gcode.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

You may want to check out this article on linear advance https://help.prusa3d.com/en/article/linear-advance_2252/

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

LA demo

Just to show the difference Linear Advance can make in a larger print...

Note: The values on the tower are the old LA1.0 numbers.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…