scarfjoint enforcer modifier

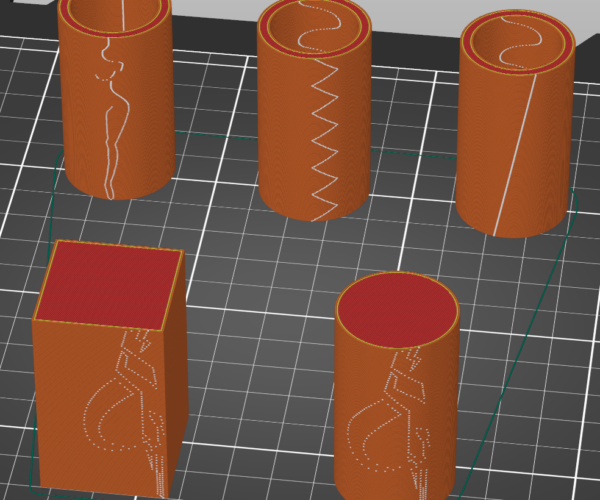

Is this a bug or a known limitation; The enforcer, cylinder in this case, only functions if the cylinder is scaled to apply to complete layers. ie I cannot force only a center pin to have scarfjoints or viceversa. I attached an example project, I tried to enforce fuzzy skin on the inner pin too and that work perfectly fine. But for scarf joints the cylinder needs to be scaled to span complete layers. Which, by coincidence, is not what I want in my current project.

no scarf joint 🙁

---------------------------

And here the enforcer is scaled to span the complete layers

behold, scarf joint!

Best Answer by Träd-E:

Here's the shenanigans I've been up to with this https://www.printables.com/model/1581166-massage-shower-head-with-exchangable-nozzle

I've mostly solved it, I'm still not 100% satisfied but using a very short scarf joint (2-4mm) in conjunction with "only on smooth surfaces" yields descent enough of a result. It doesn't really add any print time either, as using "around entire perimeter" do, however it's not quite as smooth. The problem in question is making a watertight-ish seal for a dual mode showerhead withouth using o-rings or TPU.

As I've been working on this, I think that actually being able to paint where to add scarfjoints vs normal seams would make the most sense? so if anyone at prusa reads this; do that ;D ... Then again, this is probably a highly specialized rarely need feature so .... case closed ;P

RE: scarfjoint enforcer modifier

I just now realized the file didn't attach, didn't zip it I guess..

RE: scarfjoint enforcer modifier

The whole reason why I'd like this to work is because using scarfjoints increases the average dimensional accuracy of pins and holes, especially if they are small (2-3mm)

Using random seam placement also greatly increases the average dimensional accuracy, but this option is also not available as a modifier :'(

The surface isn't necessarily smoother, in fact it's less smooth, but fitment is better and alignment also...

RE: scarfjoint enforcer modifier

"single perimeter on top surface" also seems to suffer from this bug...

RE: scarfjoint enforcer modifier

There should be more time to edit posts on this forum.... Writing samething again;

Dangit! I thought I found a workaround there for a second! Enabling "external perimeter first" on the modifier fixes "single perimeter on top surface" .. Sadly it doesn't fix the scarfjoint issue..

RE:

I'm finding more inconsistent behavior concerning this. Setting the seam position seams to affect how "smooth" the surface needs to be for "Scarf joint only on smooth perimeters" to take affect, where having it set to "rear" gives the most expected result.

Random: Scarf joints are applied everywhere, needless of geometry, ie '..only on smooth..' is basically ignored

Nearest: The diameter of a hole needs to be significantly larger to be considered "smooth" not sure exactly but a 6mm hole is consider "unsmooth" so no there scarfjoint.

Aligned: Seeeeaams .... aa aa! to behave quite the same as 'Nearest'

Rear: Behaves very well, even a hole with a 4mm diameter gets a scarfjoint while outer perimeters with some sharp edge is ignored. I do wish all joint placement settings would behave like this.

RE: scarfjoint enforcer modifier

@4thee

I'm unfortunately, going to have to be the one that points this out. Your ideation, maybe a better way to say this is, workshopping. you are missing a great deal of information! for real, you should spend more time learning about this before posting about it, there are people here that know so much more then where your knowledge is currently, and your using the forum as a notebook. Please stop doing this, it's ok to ask a question, however you have to learn other things before you can categorically state that this is this and that's that. Many people here are years and years ahead of the information you think you have. It's very important that you calm down a bit. just as an example, there was a user here by the handle "Bobstro" an very intelligent individual that could show you years and years before scarf joints how to make better seams then scarf joints can currently. However, if you used his same information and applied it to what you a newbie, knows as scarf joints you would see successful results. coming into this new, you need to slow down, and take your information slower, there is no way! you could handle the amount of information you still have to learn in one post, or even 10. Not to mention the way different versions of PrusaSlicer that have been manipulated by the developers for the worse over the years.

this was what you could do before a user by the Handle

you have no clue, these were past interactions, the Development team could have cared less.

They get paid by a company, and do what they are told. in case thats not making scene to you it means that Prusa will take your lack of knowledge and manipulate it to their, not your benefit.

and then we see this,

https://github.com/prusa3d/PrusaSlicer/issues/13410

this is one of the most uninformed comments in the history of slicer, however we watch as the Prusa Dev's who don't have a clue what users can actually do with slicer, immediately do is screw it up, they the Developers have not got a clue, or are just doing as instructed by management, meaning your screwed! They took what was awesome and removed its capability based one user who didn't know their ass from a hole in the ground. Now every user has to suffer this that is forced to use the new software because they bought new prusa hardware.

You know nothing about seams, you think you do but the information is vast, don't be the next @jurassic73. This user still hasn't figured out how they screwed things up for everyone.

Stop using the forums as your notebook, you have Sooo, much to learn. base solely on what you have posted so far you haven't got a clue how to manipulate seams. Start searching for this information, scarf joints where added to PrusaSlicer as a way to get people to shut up, all the work was done by others not by prusa. Prusa added them as so many other slap together codes, to appease the community not because they were worth their weight. volumetric's and other settings, I will not waste my time mentioning control seams and how smooth or not they may be, not to mention model characteristics and the particulars of the filament you trying to print with . good luck to you you have quite the journey ahead of you, there is no button and never will be for this.

Regards

RE: scarfjoint enforcer modifier

I missed my chance to edit this post as you only get 30 seconds to do so, but don't be the next @jurassic73 is the moral of this story. learn what your talking about before you post a bunch of crap.

RE: scarfjoint enforcer modifier

😘

RE: scarfjoint enforcer modifier

Here's the shenanigans I've been up to with this https://www.printables.com/model/1581166-massage-shower-head-with-exchangable-nozzle

I've mostly solved it, I'm still not 100% satisfied but using a very short scarf joint (2-4mm) in conjunction with "only on smooth surfaces" yields descent enough of a result. It doesn't really add any print time either, as using "around entire perimeter" do, however it's not quite as smooth. The problem in question is making a watertight-ish seal for a dual mode showerhead withouth using o-rings or TPU.

As I've been working on this, I think that actually being able to paint where to add scarfjoints vs normal seams would make the most sense? so if anyone at prusa reads this; do that ;D ... Then again, this is probably a highly specialized rarely need feature so .... case closed ;P

RE:

I forgot to mention another trick that I use in this model. For small pins and holes an effective way to get a consistent dimensions is simply adding a small triangle shaped groove, 0.2mm x 0.2mm in the model effectively removes the bulge that usually accompanies the groove where the seam is. Doing this just leaves a groove.