Remove Mesh Intersection?

Is there an option in PrusaSlicer that will allow me to overlap STLs without it printing twice the plastic in the overlapping area? I think Cura has an option called, "Remove Mesh Intersect," but I'm unable to find something similar in PrusaSlicer.

RE: Remove Mesh Intersection?

You just need to load the second object as part of the first object instead of individual objects.

RE: Remove Mesh Intersection?

I did not, but now that you've pointed it out I've played with it some. It doesn't work too well for what I've done. Might be able to get it to work though.

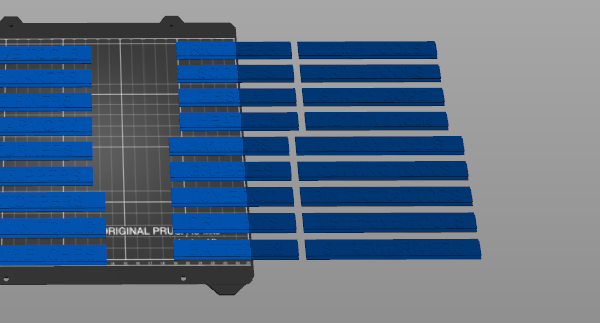

Essentially, I've made a single .3MF file with about 30 objects in it. These objects are labels that can be inserted into extrusions. I was hoping to be able to combine 1/4", SAE, and SOCKETS labels into one single label in the slicer. The alternative is to make another 30 labels in Fusion360 with them precombined.

Ultimately, the issue is when I try to add the .3MF as a part of the first one, I can't see what I'm working on. Everything in the list is named based on the name of the .3MF file and not of the components within it.

RE: Remove Mesh Intersection?

And this is what it looks like if I add the .3MF as its own thing. You can see in my attachment above that when added as part of the first object, I can't tell which parts I'm deleting.

If it can't do it, then it can't do it. I'm OK with that, I'll just make the labels how I actually want them in Fusion360.

RE: Remove Mesh Intersection?

PS uses a hierarchy. Anything on its own in the tree on the right is printed as a separate object. As such it obeys the basic rules. Things like you cant place parts off the bed such that they float in the air. They will also cause bad things if you intersect them. As each is sliced on its own that would cause multiple extrusions trying to occupy the same area. PS does NOT check for such overlap. Its up to the user.

Objects though can be made up of multiple parts. They appear in the tree as branches. They can intersect as all the parts are sliced as one object. Theres a setting called clipping for that. Its active by default. Parts CAN also be placed off the bed as long as SOME part of the overall object is touching the plater.

In 2.3 you can right click on a part of the plater and choose Add Part>Load to add more parts to an object. Or you can select multiple objects and right click and select merge. Once merged its then a multipart object.

The problem with 3mf files from other software though is that when they are loaded into PS they use the name assigned to them in that software. So if in your cad software you have parts called cube1, cube2, cub3 for example then that's what they will be called in PS too. As I use blender I often end up with cylinder.001, cylinder.002. That's not the fault of PS, that's just me being lazy and not naming objects in my CAD software.

They changed how 3mf names were handled in PS2.4 (currently in beta) as people were complaining. Cant remember off hand what they changed though sorry. Just remember a post on github about it.

@henry-2

Just a quick suggestion, if you place your labels the way you want them to print in slicer, then "export plate as .STL" then import that stl back into slicer the overlaps will be gone.

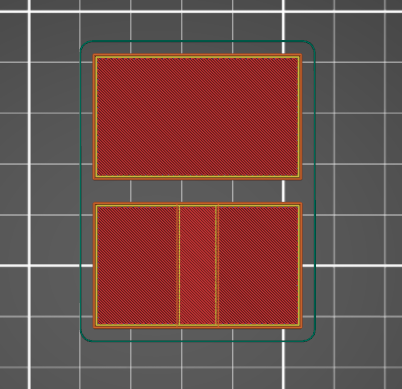

The bottom two boxes are as placed in slicer then exported,

and the top box is the exported/saved .stl imported back into slicer.

Very quick to do.

Good Luck, hope this speeds things up for you.

Swiss_Cheese

The Filament Whisperer

@henry-2

For the record, what I'm suggesting is not the same as using merge.

If you already worked it out, no worries.

Swiss_Cheese

The Filament Whisperer

RE:

Thanks! This method will work great when I need to use it. I ended up resolving my issue in another manner. Here's one example of what my conundrum was. I was using Fusion 360 to make labels for an extruded handle on a toolbox. I wanted the following labels:

- 1/4" SAE Drive Sockets

- 3/8" SAE Drive Sockets

- 1/2" SAE Drive Sockets

Then repeat for metric. Then do something similar with Phillips Screwdrivers, Flat Top Screwdrivers, and on and on with similar but not exactly the same labels. Doing each label in Fusion 360 was taking me about 5 minutes to start, then about 3 minutes towards the end. Then, if I had to tweak the label size, I had to edit every label.

My solution was to use OpenSCAD. I made an scad file to make an extruded handle label, then a Python script to call it from the command line and pass it the text I want to use. Then I updated the scad file to make more labels but with embedded magnets. Changing the size of the label is as simple as editing a few lines of the scad code then running the Python script again. Similarly, adding new labels is as simple as adding a piece of text to my Python script. I'm up to 450 labels 🤣

Thats probably the best way to go

@henry-2

I'm with you, it's always better in my opinion to do the bulk of the work in your 3d program before moving to slicer.

let us know how it goes, "next year" after you get all those labels printed and installed 🤣

Enjoy

Swiss_Cheese

The Filament Whisperer