RE: PrusaSlicer hard to remove supports

hey that's great but how does it looks like in the slicer ?

RE: PrusaSlicer hard to remove supports

These settings worked great for me in terms of making the supports easy to remove, but I'm curious if it's normal for the first layer above the supports to look like this.

Not sure what I am doing wrong despite using the exact same settings I see under this post.

RE: PrusaSlicer hard to remove supports

Hi all. New to Prusa. Been reading through this post and see a lot of good info. However it seems like there have been some advances since this thread started like the implementation of Snug and Organic supports. SO the more I read on, the more confused I get.

What is currently the best support setting for PLA for easy removal and minimal scarring. A screen shot would be a plus.

RE: PrusaSlicer hard to remove supports

These settings worked great for me in terms of making the supports easy to remove, but I'm curious if it's normal for the first layer above the supports to look like this.

Not sure what I am doing wrong despite using the exact same settings I see under this post.

This is also around what my first layer looks like after removing supports with these settings, so I would say you're par for the course here. The way I look at it, this kind of surface looks much better than it would otherwise - if you couldn't remove the parts at all. I will say, however, just speaking about supports in general, the polymer used also makes a huge difference. In my experience, PLA and PETG love to stick to themselves. This is why they are so easy to print with, but so hard to remove the supports for. On the other hand, ASA doesn't like to stick to itself, so I have found supports always pull cleanly off and support settings being much more forgiving (the drawback being you need a chamber at a minimum to print ASA and keep it from warping, and ideally some kind of activated carbon and filtration to deal with the smell).

Hi all. New to Prusa. Been reading through this post and see a lot of good info. However it seems like there have been some advances since this thread started like the implementation of Snug and Organic supports. SO the more I read on, the more confused I get.

What is currently the best support setting for PLA for easy removal and minimal scarring. A screen shot would be a plus.

I don't think you're going to find a single answer here. "What supports are best" when it comes to grid, organic, or snug, really depends on the part geometry. Personally, I have replaced grid with snug in all instances, but will happily utilize organic whenever I am faced with parts with thin or fine features, or features that require support but cannot be supported with grid or snug while still printing the supports on the bed only. I have had bad experiences removing organic when using them to support large, flat surfaces (so I use snug); and I have had bad experiences removing snug (or getting snug to actually support) when using them to support thin features or overhangs that don't have a direct vertical path to the bed beneath them.

All that said, I have also noticed more and more that not all slicers are created equally when it comes to support generation (or filament extrusion - perhaps these are related). For example, I was recently trying to slice a part in Super Slicer for printing on a new Voron 2.4 I have just finished building. I spent a lot of time building a filament profile for Super Slicer - temperature, extrusion multiplier, dimensional accuracy, the works - and had it objectively dialed in, but the prints themselves were coming up with poor surface finishes and lots of stringing (I was using PETG). I also had issues with supports collapsing before ever printing a part on them. As an experiment, I took the 3MF file, the filament settings, and the printer settings, and copied them over to Prusa Slicer, and the results were night & day: the output from Prusa was clean, almost no stringing, and it printed onto the supports first try. So, the only difference at this point was slicing engines themselves, and Prusa's did a much better job for this particular model. I am not saying "Super Slicer sucks", just that this hobby has so many different variables, you can't really copy & paste different settings and expect things to 100% work (or not work).

I will say that the advice about the support settings in this thread are still plenty valid for grid and snug supports. Even organic supports, if they need to support a large, flat surface. And if you are printing with a Prusa printer, you really cannot go wrong with using Prusa Slicer. You may not even need to tweak support settings, unless you find that the supports on your parts are proving difficult to remove.

RE: PrusaSlicer hard to remove supports

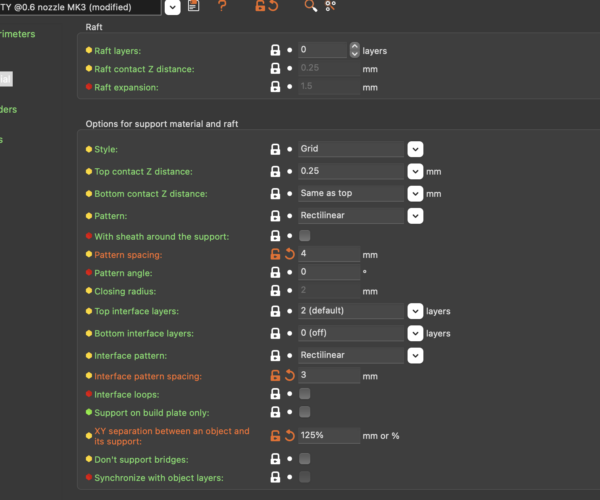

Has anyone found really good settings yet for 0.6mm nozzle with snug supports on their Prusa? I'm experimenting with settings now for my little farm of MK4S printers.

Right now I switch between 0.32lh and 0.20lh. So I deviate my 'Top Contact Z Distance' between 0.25mm to 0.37mm (0.05mm more than the slicers layer height)