PrusaSlicer 2.6.0-alpha4 is out!

Greetings all;

The feedback and bug reports have been such a help and have helped us continue to fine tune the latest Prusa Slicer version. PrusaSlicer 2.6.0-alpha4 Has been released and here are all the improvements and fixes. Please continue to assist us and keep those reports coming in 🙂 .

Summary

This is the 3rd public alpha release of PrusaSlicer 2.6.0. It mostly fixes bugs found in previous alphas, but there are also improvements, especially related to the Cut tool. For new features in the 2.6.0 series, please read the release logs of 2.6.0-alpha2 and 2.6.0-alpha3.

To let you enjoy the alpha without worries, the alpha builds save their profiles into PrusaSlicer-alpha directory, so you may use the alpha side by side with the current release without ruining your production configuration.

Cut Tool Improvements

- The Cut tool dialog layout was changed to be easier to comprehend

- Upper and lower part of the object are now highlighted in color

- Added a possibility to cut the object into parts - in that case, connectors cannot be placed and the parts retain its position within the object. Thanks @jschuh for this idea (presented in #9564).

- The controls of the tool obscured the object when it was small #9657

- Added a functionality "Flip cut plane" to easily add pins to the other side of the plane #9632

- The cut tool now works even when the cutting plane does not intersect any volume of the object, so the tool can be used to separate parts into multiple objects without actually cutting anything. This is the same behavior as in 2.5.0. #9629

- When placing connectors in the new Cut tool, the tolerance is now entered in absolute values #9697

- The cut plane is now highlighted on hover, it is newly possible to move it by dragging.

- If the object is cut into parts or when it does not have any connectors, the "lock" of scaling of the resulting parts is not applied #9633

- Performance improvements

Other improvements with respect to 2.6.0-alpha3

- The option "Clip multipart objects" was removed. PrusaSlicer now always behaves as if it was ON. This option was a candidate for removal for a long time, and the new algorithms we implemented for the 2.6 series are no longer compatible with it. We believe that there is really no reason to not clip the objects and we have seen many cases where leaving it OFF accidentally led to unexpected results (overlapping extrusions) #9679, #8779, #3872

- Increased sensitivity of the curled overhang avoidance algorithm

- 'Set Number of Instances' now works when multiple objects are selected #6994

- Organic supports are now consistently referred to as 'Organic'

- Organic supports parameters are now grayed out when different style of supports is selected

- It is newly possible to set acceleration separately for external perimeters, solid infill and top solid infill (

Print Settings->Speed->Acceleration control)

Bugs fixed with respect to 2.6.0-alpha3

- Extra perimeters on overhangs sometimes overlapped with infill #9604

- Fixed an occasional crash when using Organic supports with specific settings #9555

- Fixed a crash during slicing when certain strings were present in custom G-codes. This was also a problem in previous versions, but instead of a crash, incorrect cooling logic might have been applied in these cases #9470, #9550

- The "Export plate as STL including supports" option was grayed out in the menu when the object only had pad and no supports #9558

- Organic supports: All contours are CCW oriented, inner contours are printed before outer contours.

- Fixed crash in Organic supports with a single support layer only #9557

- Linux specific: The new "idle_temperature" option in Filament Settings did not behave correctly when checked and unchecked (UI glitches).

- Fixed a rare crash during slicing with specific geometries #9561, #9562

- "Verbose G-Code" option produced invalid G-Code when "Dynamic overhang speed" was enabled #9588, #9610

- Cooling slowdown was applied incorrectly when "Dynamic overhang speed" was enabled #9594, #9485

- "Dynamic overhang speed" would set speed to zero if the speed was percentage based and external perimeter speed was set to 0 (auto). Thanks @MGunlogson for helpful investigation of this issue in #9622.

- "Dynamic overhang speed" could violate (volumetric) speed limits #9709. Thanks @MGunlogson for helpful investigation of this issue in #9622.

- "Dynamic overhang speed" did not work correctly with Pressure equalizer feature #9485, #9563.

- The "optional" config option

idle_temperaturenow retains its value when disabled and enabled again. If the value cannot be recovered (e.g. after switching to different tab), a value of 30 is used as a default instead of 1500. Previously, the value would change to 1500 (maximum allowed temperature) when the option was reenabled. Same fix was applied to options in Filament Overrides. - When using the Cut tool on a model that was scaled, the manipulation arrows in the scene had incorrect size and the plane was not exactly in its correct position.

- Fixed double-printing of support layers in specific scenarios with soluble supports and interface layers #9647

- Organic support branches sometimes intersected interface layers

- Organic supports did not correctly work when using "Enforce supports for the first N layers" option #9477

- Organic supports did not correctly work when using "Don't support bridges" option #9493

- Various bugfixes and improvements of the Organic supports, thanks @ThomasRahm

- Organic supports ignored overhangs in specific cases, thanks @ThomasRahm #9459

- Fixed missing update of sidebar panel after orienting an object using Place on Face tool

- Experimental option "Wipe tower with no sparse layers" did not work correctly and was causing missing layers in the print #9592 #9703

- The Cut tool could not be applied consecutively when the previous cut placed exactly one connector #9576

- Fix of Physical Printer Dialog: When closing and reopening the dialog, "Host Type" field was incorrectly changed #9695

- The new placeholder

is_extruder_usedintroduced in 2.6.0-alpha2 was not expanded correctly in some cases. - Several issues with object manipulation were fixed (mostly affecting mirrored objects) #9702

- Linux specific: Desktop integration and URL registration are now separated.

- Layout fixes in the Preview dialog when an archive is being opened.

- Fixed freezing during brim generation for specific geometries #9651

- Windows specific: Selected item in Search dialog was unreadable when using dark mode

- The new autopainting of supports did not work correctly when raft was enabled

- Fixed a crash with specific geometries and elephant foot compensation enabled

Bugs fixed with respect to 2.5.0

- Linux specific: desktop integration was failing when

$XDG_DATA_HOMEand$XDG_DATA_DIRSenvironment variables were undefined #9565, #9584 - Windows specific: Fixed UI glitch in PhysicalPrinterDialog when changing the printer selection

- Extruder temperature was occasionally shown incorrectly in Preview when using single extruder multi material #8324, #9597

- Fixed a false positive error report about "Calling AppConfig::save() from a worker thread", appearing when using VM and specific nVidia drivers #7839, #9178, #9370, #9420

Profiles

Download

individual program download;

https://github.com/prusa3d/PrusaSlicer/releases/tag/version_2.6.0-alpha4

Packaged download with drivers and apps;

help.prusa3d.com/downloads

Please report any bug or issue here

github.com/prusa3d/PrusaSlicer/issues

Shane (AKA FromPrusa)

RE: PrusaSlicer 2.6.0-alpha4 is out!

Is there a method to export the file as an STL and still retain the cut connectors? In particular the holes / void created?

RE: PrusaSlicer 2.6.0-alpha4 is out!

Simple answer is no. The holes in the sliced model are made by a modifier mesh. Modifiers are applied at slicing time to influence the sliced lines (gcode). They do not actually modify the underlying geometry at all (at this time). That is a far more difficult process than can be error prone. One of the more common sources of errors in models is from boolean difference operations. Which is exactly the type of operation needed for this process.

Its why when you export you either lose them completely or actually get posts as the modifiers become normal solid geometry. While the PS function is an ok feature it is still far better to do CAD tasks using CAD software.

RE: PrusaSlicer 2.6.0-alpha4 is out!

Sorry if this is the wrong place to comment - but I didn't find any better place after looking + searching for PrusaSlicer.

I have just finished a Print on my MK3S with the 2.6.0-alpha4 and it looks amazing everywhere - Except on the bottom layers (they don't look bad - but not fused together with neibors). Result with a 1.2mm wall thickness PLA is that it LEAKS water out through the Bottom Layer (closest to Bed) and this wasn't a problem with 2.5

I did notice that the First Layer didn't look as 'Flat' as it usually do @ the beginning of the Print - like I need to Re-Calibrate First Layer .... but as I have only changed the Slicer - this doesn't make sense .... Or maybe it do - When comparing the previous (2.5.0) with the latest (2.6.0-alpha4) - I see more 'Strings/Lines' closer together from 2.5.0 vs less 'Strings/Lines' more spaced on 2.6.0 on the Top and Bottom Layer - with the Bottom one having the biggest difference / spacing.

As I just allowed the 2.6.0-alpha4 to reuse my old preferences - I wouldn't expect any differences here.

Just to be sure - I have loaded the G-Code file back into Slicer 2.5 Wiever - and the first layer is shown as 0.2mm and the following as 0.15mm

RE: PrusaSlicer 2.6.0-alpha4 is out!

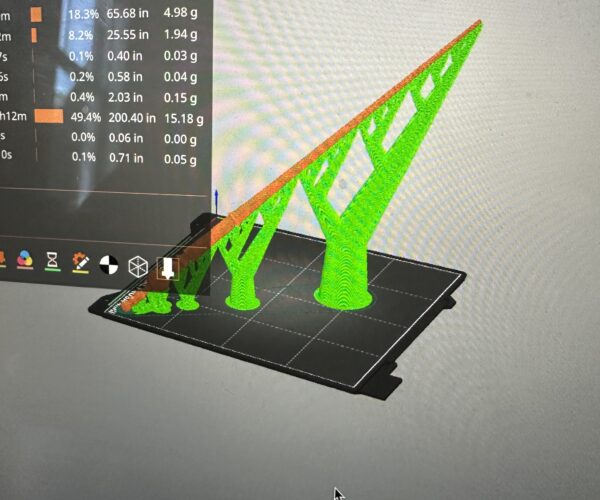

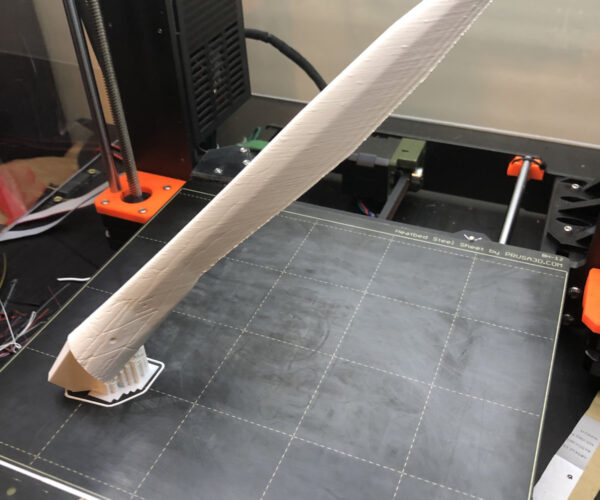

Organic supports is cool. The supports in the below print are hollow, though, so that they are just hollow columns. Failed print. Is there a way to have the organic support have a fill so that they are more stable? Can’t figure out any settings that do this.

2.6.0-alpha4 cut tool

Any idea what I'm doing wrong with cut tool? I select object, select cut tool, drag cut plan to where I want to make cut, edit connectors, select dowel (which I thought should make dowel holes in each new part and also create dowel pins), confirm connectors, both objects are selected with "keep orientation", Cut to: Objects is selected and once I select peform cut, it makes the cut but overlaps the two parts, creates dowel pins but also has dowel pins inserted in each part. See screen shot.

RE: PrusaSlicer 2.6.0-alpha4 is out!

@3ddavidson

I'm guessing you are very new to prusaslicer. For starters you did the procedure correctly, you may have only forgotten to do one thing, and that's size your dowels for tolerance, this is not done automatically because different materials will have diffident needs. It's normal for Slicer to place the parts on top of each other like that after cutting, you just have to select them if they are overlapping and move them so that they aren't.

The pins that your seeing in/on the model are not dowels, they are Negative Volumes marking the whole positions, and at the time of rendering will create the wholes for the dowels, you would have seen this if you had pressed the Slice now button.

Anyway I hope that's got you sorted, have fun with it and play lots.

RE: PrusaSlicer 2.6.0-alpha4 is out!

No, I'm not new to Prusa, I've been using it a long time. I am new to 2.6.0 alpha4. When I "perform cut", prusa groups the bottom part, the upper part and the dowels all as one object. But I did find that you can ungroup them by selecting the "arrange" tool.

RE: PrusaSlicer 2.6.0-alpha4 is out!

@3ddavidson

When you "perform cut" with the settings you used, slicer is actually breaking your single "Object" into multiple "Objects", Not Grouping them together. After it splits them to "Objects" if you have selected dowels, the "Dowels" are split to separate "Objects" and printed as such, If you have 4 dowels you will see 4 new objects created in the "Object menu" named Dowel-Connector 1-4 by default. If you cut your original "Object" in two then slicer will also turn each of those half's into individual "Objects". Again If "Dowel" was selected, Slicer will add a Negative volume in the appropriate areas based on your selections before you "perform cut" at the time of render those Negative Volumes will become the aligned Holes for the dowels, as I mentioned to you in the previous post, you might want to consider adjusting the tolerances of the dowels.

After you "perform cut" all the New "Objects" in the "Object menu" are selected (Highlighted Green) by default, Not Grouped, you can simply left click anywhere on an empty area of the Platter, away from the selected "Objects" they will be deselected, and you can then simply left click on any of the new "Objects" created by the cut process and move it around on the platter.

Your image shows that you had Cut to: Objects selected, you had "Object A" (That's the top of the cut) Set to "Place on cut", and "Object B" set to "Keep orientation". You chose to use 4 Dowels so four dowels where created, they each of the dowels became a separate object, the dowels are the only new thing going on here, in previous versions of slicer (this is why I guessed you were new to slicer) it has always preformed the cut the same way, turning one object into 2 objects and dropping the new object to the bed overlapping a portion of the other, offset by 45°.

My assessment was not designed to embarrass you, but rather to offer an assessment of where I perceived your knowledge level of slicer based on the question you asked, it effects the answer.

Apologies if it had that effect, I'm a very blunt person. I find we waste less time that way.

RE: PrusaSlicer 2.6.0-alpha4 is out!

I have tried to print the same file again and lowering the first Z value 18µm. This almost did the trick - this print looks like the ones done with slicer 2.5.0 and do not leak when there only is a low water pressure - higher pressure results in a tiny amount of water leaking out.

So re-adjusting the Z-First-Layer flatned the layers to look like Slicer 2.5.0 all the way up to 30mm above the printbed (top level of that print).

Only other difference I forgot to mention above (a few days back), is that I ran out of Yellow PLA Prusament => the Prints with Slicer 2.6.0-alpha4 are done with Grey PLA Prusament ...! Should I expect to use a different Nozzle Temperature (or similar) between the two, to get the same end-result ?

RE: PrusaSlicer 2.6.0-alpha4 is out!

pls see my screen attached, I'm unsure if you like the tree growing trough a little hole

also my support-blocker-object didn't prvent this tree to grow even when I made it higher while paint-on-blocker worked

RE: PrusaSlicer 2.6.0-alpha4 is out!

can I change the wall-count for the ocganic support?

would be great to only have one shell wherever possible