Method for massive reduction in support material (suggestion)

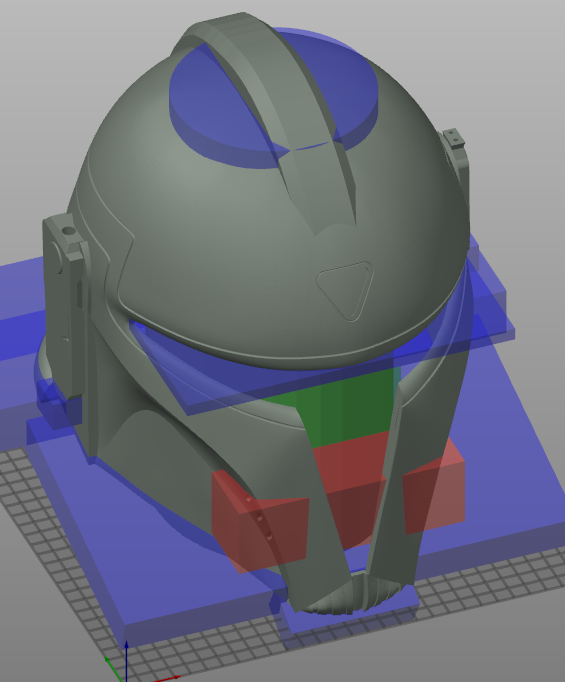

I came up with a relatively simple method to reduce support material in prints especially those that require large, high support structures such as cosplay masks and architecture models.

A horizontalish surface that requires support is printed on a couple of layers of dense support. Currently below that is a vertical mesh of support that is generally rectilinear walls spaced 2mm apart, but here's a great improvement to save print time and support material.

I'm suggesting a first, coarse support structure on top of which normal rectilinear support is built and finally a dense support to interface the printed part. This coarse support structure can be pillars or sparse walls but towards the top expands diagonally to form a solid surface (that does NOT require its own support the way a cathedral's ceiling holds its own).

My thinking is that a good rigid structure can be a grid of around 20x20 mm where each pillar converges at its top in a pyramid with 45 deg. walls to create a solid self supporting surface. On top of this elevated spiky landscape, 2mm rectilinear support closes the gap to the dense support just like before.

I simulated the savings with a model in fusion360 (see attached) supporting a random curved surface. 2mm rectilinear support came out 244gr. while using a coarse support w/ 2mm rectilinear on top as suggested came out only 75gr ! that's less than a third !

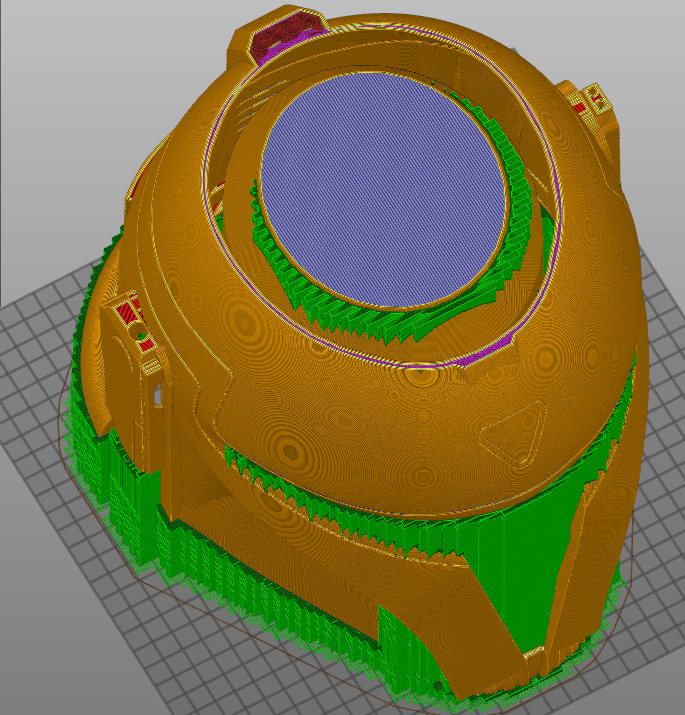

Reuse algorithm in "Support Cubic" for support

When using the "Support Cubic" infill PrusaSlicer does a similar to infill, as you suggest.

Here a sample model:

Here the Infill+Solid infill with perimeter+top+bottom removed:

Bottom has very sparse infill, increasing to dense infill just where support is needed.

Should be possible to reuse the algorithm for regular support.

Have a look at my models on Printables.com 😉

The default support settings (in all slicers) are intended for quick and dirty printing and as such will be sufficient most of the time but rarely optimal.

For critical objects it is always best to include custom supports as part of the original design.

Cheerio,

@diem nailed it. The current supports are a compromise. At least in my hands, they do the job for most models. I think the method proposed here is sensible but probably doesn't save a meaningful amount of material unless you're dealing with large objects such as the cosplay masks the OP suggested. Adding supports as part of the design is a good strategy to optimize a print. I have some models I designed with long vertical tubes and designed breakaway supports to hold them in place.

Another reasonable strategy is tree supports. The Prusa team has done a great job in the 2.4 version to rein in the insanely aggressive support strategy in versions prior. I hope they won't be resting on their (well-deserved) laurels and continue the good work on supports. Tree support would be nice, or as @area51 has pointed out, maybe adopt the adaptive cubic or support cubic infill strategies to supports, with results that should be similar to what the OP suggested.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

reduction in support material

Thank you @fuchsr @Diem and @Area51 for your great ideas

I wasn't aware of upcoming support improvements in PrusaSlicer 2.4 and thrilled to try them out !

Personally, I don't care much about wasting some material to supports but I DO care about the print time which can sometimes be dominated by supports.

I'm pretty handy at modelling and can design for printing with custom supports or no supports (sometimes) but that can't be said for the majority of printer owners, or applied even to myself when printing STLs off the web. Such manual support optimization can also require more patience then I'd prefer to invest in a one-off print.

This issue was raised in a local whatsapp group with teens trying to print cosplay masks without wasting too much material which triggered my thought process so it's definitely a request from the slicer for more novice users.

I realize that I should probably have opened a new feature ticket in "report an issue" rather than this forum. Do you recommend I do this too?

RE: Method for massive reduction in support material (suggestion)

For helmets I used to add a modifier in the middle and that can then print with minimal walls and minimal or no infill settings, the slicer will then add support between the modifier object and the top of the helmet. Similar technique to the OP but achieved slightly differently.

Those were done back before paint on supports was a thing and all we had were the modifiers 🙂

AKA the Days of Darkness...

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Method for massive reduction in support material (suggestion)

The underlying issue is that supports, where necessary, are really part of the design; see @neophyl's example above, very few published designs include them. Quite often support advice is included in the printing guidelines for a part, there the designer has evaluated the defaults and found them satisfactory.

So far so good, but a huge proportion of published 'prints' are, at best, early prototypes and in many cases have never been printed at all; this category even includes files that must be paid for...

As a rough guide for beginners: Never attempt to print any download that does not include a photo of a finished object and always read the comments first. Be aware that some perfectly good designs may be intended for a different printing technology.

Until recently prusaprinters has been relatively free of such designs but with the recent problems at thingiverse they are beginning to creep in.

If you can turn your method into a library for one or more of the popular 3D cad programs it may prove very useful for those making custom support at design time.

Cheerio,