2nd layer fails with prusaslicer but works with cura

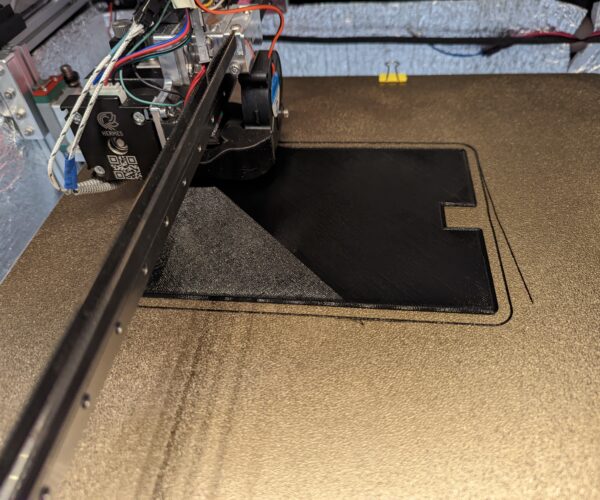

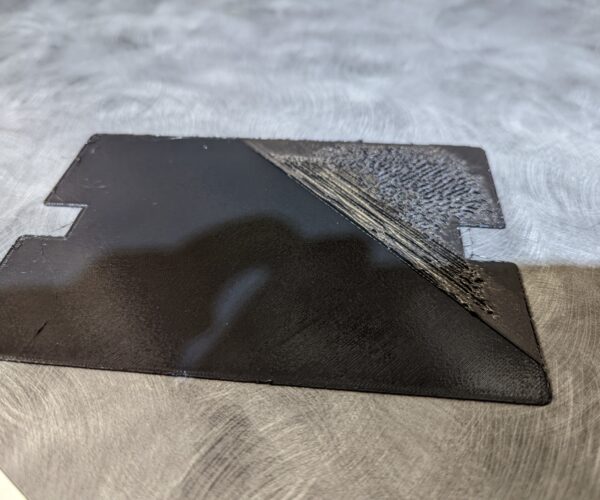

I'm puzzled by a problem I'm having with prints using prusaslicer. I have a largish flat print (cover for resin printer vat) where the second layer fails to stick with prusaslicer but works with cura. I tried 8-10 variations of nozzle height, bed temp, print temp, speed using prusa slicer and the print kept failing on the second layer. The layer splits and the edges peel up. I finally tried basically the same settings using cura and it worked the first try. I can't figure out what the difference could be. I see that prusaslicer has a wider extrusion width on the first layer, but that seems like a strange thing to cause the second layer to fail. Any ideas what causing the problem with prusaslicer but not cura?

I've been using prusaslicer for a few weeks now without problem, but this is the first large flat print that I have tried.

.4 nozzle

polymax pc

PEI textured bed

Cura

no cooling

layer height .2

first layer height .3

line width .42

first layer line width 100%

hotend temp 270

Bed temp 90

Flow 100%

Print speed 50mm/s

top/bottom speed 40mm/s

Initial layer print speed 25 mm/s

Prusa

no cooling

layer height .2

first layer height .3

line width 105%

first layer line width 150%

hotend temp 270

Bed temp 90

Extrusion multiplier 1

Print speed 50mm/s

First layer speed 40mm/s

RE: 2nd layer fails with prusaslicer but works with cura

First off PrusaSlicer 2.4.0 final has some massive fails, that they don't seem to want to acknowledge, I've had several occasions that they have asked me what the problem is and I have tried to show them prior to the latest release, but they don't listen, BTW I don't have time in my life for that BS, I'm an extremely educated user. bottom line is they have their way of releasing Prusaslicer and SuperSlicer has it's way. I think that super slicer has a way better then prusaslicer has of listening, and frankly I think that Cura has a better development team then Prusa has at the moment, I would be more prone to mention the problems to cura then I would to Prusa as Cura seems to actually want to fix the problems then seem to want to pretend they didn't exist. Prusa Slicer has some catching up to do despite the newbies that don't understand what slicer is actually capable off. this is going to be and is now a real problrm. you newbs that make requests not understanding how to really use the software are destroying it's usefulness.

Don't care about how you feel About this now, you will care later when you learn what it takes to be proficient with the software, it's to bad that your uneducated opinion is effecting it now.

Swiss_Cheese

The Filament Whisperer

RE: 2nd layer fails with prusaslicer but works with cura

PrusaSlicer is my go-to slicer for the Prusa printer, but I also use Cura occasionally (and for my 'other' printer, an Ultimaker).

I admit that I've been hesitant to use the 'latest and greatest' PS releases when they first come out due to issues reported here and elsewhere on new releases. (I've also been hesitant to use the 'latest and greatest' Cura releases for the same reason as well.)

I've never printed with the Polymax PC, but it looks like the recommended settings are in the ballpark with the Prusament PC Blend, which I've used and had good luck with.

I also can't remember having specific second-layer issues with anything. Your photo above shows some definite issues with the second layer, but from the photo I can't identify a particular issue.

In my experience, also, PS tends to handle the first layer on the Prusa printer better than Cura does, particularly with PLA, but I've worked around this by slightly tweaking the first layer speeds.

If this were mine, I might try backing down to an earlier and known-stable PS release to see if there's any difference.

RE: 2nd layer fails with prusaslicer but works with cura

First off PrusaSlicer 2.4.0 final has some massive fails, that they don't seem to want to acknowledge, I've had several occasions that they have asked me what the problem is and I have tried to show them prior to the latest release, but they don't listen, BTW I don't have time in my life for that BS, I'm an extremely educated user. bottom line is they have their way of releasing Prusaslicer and SuperSlicer has it's way. I think that super slicer has a way better then prusaslicer has of listening, and frankly I think that Cura has a better development team then Prusa has at the moment, I would be more prone to mention the problems to cura then I would to Prusa as Cura seems to actually want to fix the problems then seem to want to pretend they didn't exist. Prusa Slicer has some catching up to do despite the newbies that don't understand what slicer is actually capable off. this is going to be and is now a real problrm. you newbs that make requests not understanding how to really use the software are destroying it's usefulness.

Don't care about how you feel About this now, you will care later when you learn what it takes to be proficient with the software, it's to bad that your uneducated opinion is effecting it now.

Swiss_Cheese

I use PrusaSlicer because I thought it was the best slicer, seems like I may be wrong. I tried Cura and a couple of others but they didn't seem to stick. I wonder maybe if I was swayed by the aesthetics.

I would be very interested in a list of faults in Prusaslicer so that either i can work around them or adopt a different slicer.

RE: 2nd layer fails with prusaslicer but works with cura

Correct me if I am wrong please.

My impression is that PrusaSlicer is primarily maintained and updated by volunteers, as opposed to a full-time paid professional development team.

Is this notion correct or incorrect?

RE: 2nd layer fails with prusaslicer but works with cura

@iporty IMHO your problem is a partial hot end block, which is masked by different settings in Cura.

RE: 2nd layer fails with prusaslicer but works with cura

JSW, I think that is incorrect. The Prusa Slicer main team are employees of Prusa, there are certain pull requests made by external people but the Prusa team always has final say on if they are merged into the releases.

RE: 2nd layer fails with prusaslicer but works with cura

Ok, then I stand corrected.

I'm trying to think how I got the impression that it was volunteer driven, but I can't remember specifically.

RE: 2nd layer fails with prusaslicer but works with cura

Possibly because it is still open source. Anyone can check out the code, see how its structured, make changes (locally on their machine) and build it. Assuming you have that skill set.

Only certain people have write access to the repositories though and that's what the releases are built from.

Nothing stopping anyone from cloning them and forking a new software version. Which is essentially what versions like Super Slicer are, although with many changes for SuSi as its been going for awhile.

RE: 2nd layer fails with prusaslicer but works with cura

I did try swapping out the nozzle from a nozzle x to a brass nozzle with prusaslicer and that did not make a difference. When running cleaning filament through the nozzle, it looked normal to me. But there's always the possibility that there is some partial blockage.

Original Slic3r perhaps?

Ok, then I stand corrected.

I'm trying to think how I got the impression that it was volunteer driven, but I can't remember specifically.

You might be thinking of Slic3r, which (IIRC) was an open source project with 2 primary volunteer maintainers. PrusaSlicer was originally based on Slic3r, but forked off and was more-or-less rewritten in recent years to the point that they no longer resemble each other much. PrusaSlicer is still open source, but Prusa has paid developers working on it. I recall reading something from one of the original Slic3r developers responding to a complaint with something like "they are paid and more power to them".

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE:

I'm puzzled by a problem I'm having with prints using prusaslicer. I have a largish flat print (cover for resin printer vat) where the second layer fails to stick with prusaslicer but works with cura. I tried 8-10 variations of nozzle height, bed temp, print temp, speed using prusa slicer and the print kept failing on the second layer. The layer splits and the edges peel up.

Hard to say without doing a setting-by-setting comparison, but I have seen this behavior before. The key is that the 1st layer PrusaSlicer is printed at a much slower rate. You didn't show your infill speeds, but Prusa's infill speeds are often "overly optimistic" with 200mm/s for some settings, depending on the profile selected. This is ignored on the 1st layer but is applied on the 2nd and up.

This will be more of a problem on largish prints with large, flat infill areas in which the nozzle can move up to speed. If you exceed the maximum volumetric rate of your nozzle + hotend + filament, top surfaces can be rough, and rough surfaces snag and make a mess over time. The first thing I'd try is simply slowing way down. You could just dial the print speed back with the front knob to 50% mid-print to verify. If that helps, calibrate your maximum volumetric rate to something reasonable for that filament. If PC is more viscous than typical filaments (I don't use it so can't say), this could explain what you're experiencing.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…