RE: HOMING ISSUES

I did get the calibration to work, once completely. It's when I decided to print; there was a HOMING issue. The issue is always with the belt and the HOMING. Everything else in the calibration is when done multiple times successful. Although that is not with the HOMING and Y-axis.

I'm always dissembling my nextruder to fix the belt; then adjusting the tension and I fight this over and over again. Although I never get to actually printing anything.

I got the calibration from beginning to end working successfully; then I tried to print; HOMING error. Now the belt is extremely loose on the X and even the Y. It looks like once again, I have to remove the nextruder.

When you say "extremely loose" is it actually pulling out of the Nextruder belt harness? Also, how are you tensioning the belts? Have you clicked on the link and read the guide I sent you earlier?

@butters, I want to help you but you have to help me. Please take detailed photos of your belts and how they are routed along the frame. Also, please describe how you are tensioning the belts.

Don't know what country you are in but in the US we have a service called Task Rabbit where you can hire someone to do various tasks like assemble furniture or do anything really. Maybe you should hire someone locally who can help you.

RE:

When I calibrate once, and it manages to pass calibration; the second time it fails. How can I tweak nothing, and it fails, it should pass again. Well, if I can't get this to always pass calibration then I'll just give up on getting it work. I'll keep it as a book holder.

RE: HOMING ISSUES

I think I'm just gonna give up on getting it to work.

RE: HOMING ISSUES

Thanks to everyone who helped.

RE: HOMING ISSUES

I absolutely concur with @hyiger, without a set of clear pictures there is no chance anybody acn controbute any help specific to your case. It sounds really weird that you need to keep reattaching/reseating the belts but, without visuals, no chance to help...

RE: HOMING ISSUES

I decided to read up on another troubles they have had with the belt and getting it work with the nextruder holder. Therefore here is some of my most recent picture; at this point I have the belts though but getting 4-5 teeth though the holder for X-axis & Y-axis and getting them to stay, that is the most difficult.

RE: HOMING ISSUES

I read, the more teeth the better; I gave it more teeth. Each time I give less teeth, it slips out.

I decided to read up on another troubles they have had with the belt and getting it work with the nextruder holder. Therefore here is some of my most recent picture; at this point I have the belts though but getting 4-5 teeth though the holder for X-axis & Y-axis and getting them to stay, that is the most difficult.

Thanks for the photo it help a lot. This is way too many teeth exposed. I'm counting 10-12. You only need to pull through 4 - 5 teeth at the most.

RE: HOMING ISSUES

I decided to read up on another troubles they have had with the belt and getting it work with the nextruder holder. Therefore here is some of my most recent picture; at this point I have the belts though but getting 4-5 teeth though the holder for X-axis & Y-axis and getting them to stay, that is the most difficult.

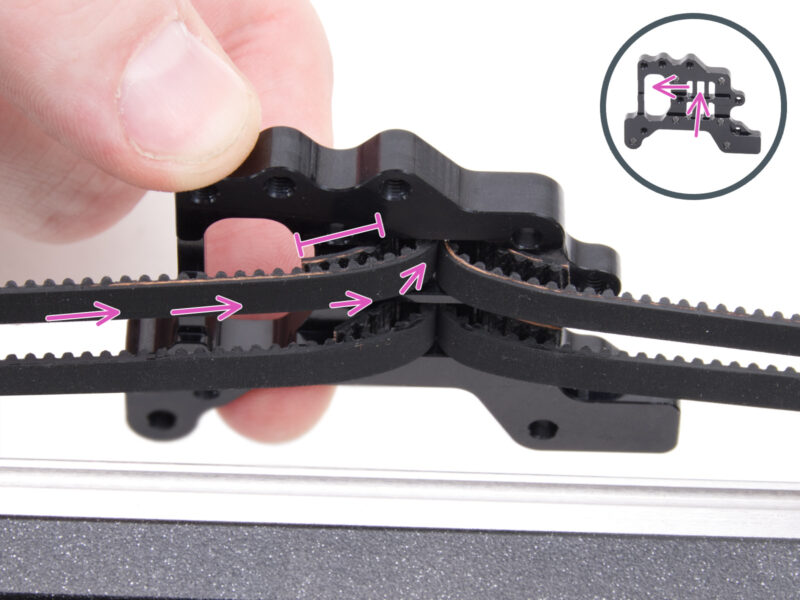

Is that your photo, of your own printer? The belt ends are inserted wrong! The ends must not stick out freely. They must be looped back through the guides, such that they are pressed against the incoming belts, teeth against teeth.

Please examine this picture from the assembly instructions. Examine it closely, look at it with an open mind, compare with your own installation. Hopefully you can see the difference and correct your belt attachment. Then the regular 4..5 clamped teeth will secure the belts with no chance of slipping out.

RE:

To clarify, my above photo shows the back view of the Nextruder mounting plate, before it is attached to the gantry. It is from this step of the assembly instructions:

https://help.prusa3d.com/guide/5-corexy-assembly_835522#864874

After attachment to the gantry, it must look like this;

https://help.prusa3d.com/guide/5-corexy-assembly_835522#864970

You can only insert the belts properly when you detach the plate from the gantry. After you screw it back onto the gantry, the belts will be clamped tightly.

RE: HOMING ISSUES

I know I have to loop it around; I took a picture of it before the looping part. I thought that this would have been realized in the picture of my return to this thread post.

RE: HOMING ISSUES

Please show us a photo of your completed assembly too. (After attaching the plate to the gantry, but before putting the Nextruder back on.) Thanks!

RE: HOMING ISSUES

The goal here is to stop having to remove the nextruder; as I've done it numerous times. And eliminate all HOMING errors. I got full calibration once successful, although when I tried to print, I got the HOMING error.

RE:

OK, got it. But before you attach the nextruder please take some images of the belt carriage. The belts should not be slipping out if they are correctly routed. Start by unscrewing the belt harness from the linear rail then loop the belts back into the harness. Take a photo of the back of the harness before you attach it the linear rail. Only 4 or 5 teeth should be sticking out. Next take an photo of it after you have reattached it to the linear rail.

RE: HOMING ISSUES

The goal here is to stop having to remove the nextruder; as I've done it numerous times. And eliminate all HOMING errors. I got full calibration once successful, although when I tried to print, I got the HOMING error.

Yes, that is the goal. But what is the present state? If you have not reattached the Nextruder yet, please provide a photo.

I will go offline now; bedtime for me. See you tomorrow!

RE:

I made sure all those teeth were pulled out, I know they can't stay at that to loop them though, a few are going to slip. Then I took that picture. When the two flat parts of the belt are side by side that is the difficult part. Therefore atleast I have 10-12 teeth and I can loose more then half upon looping. The gantry has a smooth motion when moving, no noise.

OK, got it. But before you attach the nextruder please take some images of the belt carriage. The belts should not be slipping out if they are correctly routed. Start by unscrewing the belt harness from the linear rail then loop the belts back into the harness. Take a photo of the back of the harness before you attach it the linear rail. Only 4 or 5 teeth should be sticking out. Next take an photo of it after you have reattached it to the linear rail.

RE:

I made sure all those teeth were pulled out, I know they can't stay at that to loop them though, a few are going to slip. Then I took that picture. When the two flat parts of the belt are side by side that is the difficult part. Therefore atleast I have 10-12 teeth and I can loose more then half upon looping. The gantry has a smooth motion when moving, no noise.

OK, got it. But before you attach the nextruder please take some images of the belt carriage. The belts should not be slipping out if they are correctly routed. Start by unscrewing the belt harness from the linear rail then loop the belts back into the harness. Take a photo of the back of the harness before you attach it the linear rail. Only 4 or 5 teeth should be sticking out. Next take an photo of it after you have reattached it to the linear rail.

OK, now I'm confused.

Do me (us) a favor. Just before you attach the Nextruder, please take a photo of the belt harness. Do not re-attach the Nextruder until we have a look.

RE: HOMING ISSUES

What I meant was, the belts, the flat side of the belts have to go together; they slip easily therefore it will reduce the 10-12 teeth to 3-4.

RE: HOMING ISSUES

What I meant was, the belts, the flat side of the belts have to go together; they slip easily therefore it will reduce the 10-12 teeth to 3-4.

It doesn’t work like that. Please pay attention to the photos I sent. The belts have to be looped back into the harness