Use free span frequency (Hz) to check and set belt tension

I am curious why the belt tension specification isn't taking advantage of span frequency measurement. This is common practice in industry.

I use this free app.

https://play.google.com/store/apps/details?id=com.contitech.ptg.Tension2Go&hl=en

https://itunes.apple.com/us/app/tension2go/id585560650?mt=8

and there are many others that would work.

back 'in the day' there were expensive meters from the manufacturers but now this technology is free if you already have an Android or iOS device.

I have just started assembling my mk3. I set my belt tension to my best guess and it measures 83Hz.

To check I turned the printer over and with the phone close to the bottom span (the long span) and strummed the belt (like a guitar). If one weighs the belt and measures the free span and then does the math. However, since I don't know the desired tension in Newtons for now I'll just use this relative reference. Does anyone else have a measurement reference or suggestion for tension using this measurement.

thanks!

Mark

Re: Use free span frequency (Hz) to check and set belt tension

I build bicycle wheels and a lot of people build wheels the same way. I however am a bit tone deaf and instead measure deflection using a tensiometer calibrated to the spokes I'm building with using a custom calibration rig. Same principal though. I'm pretty meticulous when I build wheels so I'm already pondering what the best belt tension will be as I know over tension is as bad as under tension.

Re: Use free span frequency (Hz) to check and set belt tension

Great idea. Problem with X belt is the "free" span can hit the carriage channel if you pluck it. So you likely won't get a good reading.

Re: Use free span frequency (Hz) to check and set belt tension

Great idea. Problem with X belt is the "free" span can hit the carriage channel if you pluck it. So you likely won't get a good reading.

That's a valid concern but moving the carriage to the side gets around that. I got 103Hz for the span on the X axis. That axis is longer so the higher reading means the X axis belt is a lot tighter than the Y. I'll just have to see how that turns out when I start printing.

Re: Use free span frequency (Hz) to check and set belt tension

After a few prints I checked the tension again

X axis 88 Hz (was 103Hz when freshly assembled)

Y axis 74 Hz (was 83 Hz when freshly assembled)

The belts are lower tension now which is what I guessed might happen. I don't have experience with these exact belts but other belts I've used in industry such as multi-v (poly-v) belts must be installed with higher tension than what you desire because they drop 10% or 20% shortly after installation.

Here is an mp3 recording of plucking the X axis belt

https://www.dropbox.com/s/meu0z17npfl32x0/x%20axis%2088Hz.mp3?dl=0

And the Y axis belt

https://www.dropbox.com/s/c7dt03tjufnduox/y%20axis%2074%20Hz.mp3?dl=0

In both cases I moved the carriages near one end of the axis (but not resting against the hard stop at the end). I plucked the longest free span at the center and recorded several plucks.

I hoped to measure the tension with a smartphone app as I wrote earlier but I have to admit this is a little challenging. Some phones will have trouble with the microphone picking up this low frequency in part because it is hard to get the microphone close to the span. An alternate way is to use the open source software Audacity and spectrum analysis to pick out the tone. I used a cheap lapel mic plugged into my pc to make the mp3 files linked above. Finally, one can use your ears if you have a lot of experience and know the correct tone.

I am really curious to know what the meaning is of the Belt Status that exists in the Prusa firmware. The printer can display numbers that are somehow related to belt tension but I don't know how they are derived so it's hard to know if they are reliable. Does anyone know how those numbers are created?

Re: Use free span frequency (Hz) to check and set belt tension

I'm sorry, I don't have the answer, but interesting post!

Re: Use free span frequency (Hz) to check and set belt tension

100 hz (x), 153 hz (y). Belt status gets me about 260 on each after self test.

I just removed the back plate to retension the X. I printed a new backplate, but decided I'm not up for rewiring the whole einsy board to replace it! So I tensioned the belt, ran a self-test and frequency measurement and I'm now reassembling.

Re: Use free span frequency (Hz) to check and set belt tension

What settings did you guys choose on the Android app??

Re: Use free span frequency (Hz) to check and set belt tension

It doesn't matter what belt settings are used, I didn't choose anything at all. I just look at the "Hz" value which will not change no matter the settings. However since you asked I looked and noticed a sensitivity setting. 🙂 That will be very handy and I suppose will be different depending on your phone's microphone.

The intention of the settings is that if you have the data for the belt (span distance and mass per unit length) then you can have the display read in lbf or Newtons. I have done those calculations for work in Excel but in this case since I don't know the desired span tension I was just looking for a relative measurement.

There are also various tuner apps that can be used instead of the ContiTech app such as guitar tuners and so on. The problem with guitar tuners is that they might only show the notes and not the "Hz" directly.

Re: Use free span frequency (Hz) to check and set belt tension

My Y axis belt seemed to be a bit loose after doing 4 test prints and I had installed my Y-tensioner fully tight when building so I had to re-install the belt to move it 1 tooth in the clamp.

Here is history of the Y belt tension over NEW to just about 1 week old and just 4 little prints

Y

Span Vibration (Hz) ,Belt Status, Notes

83Hz, ?, NEW

74Hz, ?, after a few prints

70Hz, 296, After 4 prints

---------------------------------------------------------------------------------------------------------------

121Hz, 261, Redo – move belt 1 tooth in clamp

127Hz, 257, + 1/2 turn more on top tension screw

132Hz, 253, + almost 1/2 turn on top tension screw

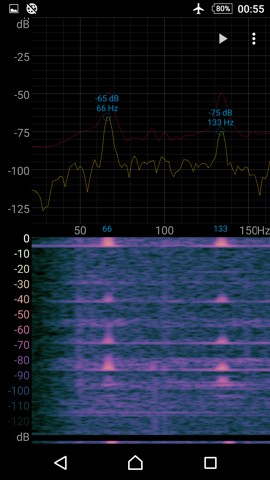

This image shows what a belt tension reading looks like in the Contitech app.

Re: Use free span frequency (Hz) to check and set belt tension

Fantastic idea... I come more from the direct drive/air bearing corner and have never had to deal with belt tension measurement. Providing the correct tension (or resonant frequency) would be a great addition to the build instructions. Someone needs to tell Josef...

BTW I use the Park tool TM-1 spoke tension meter for my bikes. It comes with a table that tells you the required tension depending on spoke diameter and material. Haven't used it a lot though, once you have a reference "feeling", you can adjust tension by ear. (I assume you mean spoke tension as you reference wheel assembly and not drive belt (Gates or such) tension)

- Martin

- Martin

Re: Use free span frequency (Hz) to check and set belt tension

I got my MK3 kit just recently and used the free Android-App "Spectroid" for the frequency measurements, which I can highly recommend ( https://play.google.com/store/apps/details?id=org.intoorbit.spectrum&hl=en ).

X-axis: 50Hz (lower span, => Lx=0.38m) or 74Hz (upper-right span while motor has been pushed to the left => Lx=0.265m).

Y-axis: 66Hz (lower span => Ly=0.295m)

Respective Prusa belt status readings: X:273, Y:272

The relation between frequency f and belt tension force F is roughly f=5.34*sqrt(F)/L, or F=(f*L/5.34)^2 respectively (with units f/[Hz], F/[N] and L/[m]) ( https://en.wikipedia.org/wiki/String_vibration ). The belt constant 5.34 is what I measured in a separate experiment.

Note that the Prusa values indicate the motor load. From the TMC2130 datasheet:

SG_RESULT = stallGuard2 result respectively PWM on time for coil A in stand still for motor temperature detection.

Mechanical load measurement: The stallGuard2 result gives a means to measure mechanical motor load. A higher value means lower mechanical load. A value of 0 signals highest load. With optimum SGT setting, this is an indicator for a motor stall. The stall detection compares SG_RESULT to 0 in order to detect a stall. SG_RESULT is used as a base for coolStep operation, by comparing it to a programmable upper and a lower limit. It is not applicable in stealthChop mode.

Prusa's firmware appears to take many SG_RESULT readings while the motor moves, and reports the averaged values.

The motor load increases with higher belt tension, which is why the Prusa values correlate with belt tension. But these values also reflect the level of general friction, which makes it interesting to compare frequency to Prusa readings. A too low Prusa value for a given frequency would indicate some problem with the axis - a bad bearing, for example.

BTW, if I loosen my belts completely, the Prusa value is 275 for both axes. Hmm, still well within the supposedly valid range; on the other hand not too far from the values measured for my considered-to-be-good belt tension. Maybe the MK3 needs some more wear-in time for getting the axes to run smoother. Anyway, would be interesting to see the Prusa values other users get for the low-tension case (and with which firmware).

Unfortunately, the Prusa values also change with the motor's current settings, which might explain why some users (including me) are having problems to get these values close to what Prusa suggests (240±40, high values = low tension) and why Prusa suggests such small values in the first place. If I set my Y-tensioner to full tension, which is plenty of tension - uh! -, I get fy=90Hz and a Prusa value of 268. I wonder how one would ever get to a value of 240, let alone 200?

Anyway, regarding the motor current, the values mentioned here were measured with the firmware defaults (v3.1.3, TMC2130_CURRENTS_R={16, 20, 28, 36}), which can also be found with the command M913.

Some interesting reads regarding the topic.