MMU2S With Revo is AMAZING (thanks to prusa support)

Big thanks to Rodolfo from Prusa Support for all of his help. I had the worst MMU experience with the v6. It literally killed it by somehow carbonizing the PTFE tube in the heatbreak. With the Revo, however, I am getting literal perfect tips. They are perfectly loaded and unloaded from the machine. Again, I talked a few times with Rodolfo on different occasions, and he was amazingly helpful. If Prusa people look at this, he needs a raise after sitting with me, troubleshooting for hours. It finally works, here are his provided settings that just work! I am so happy that this unit finally works consistently for me! These settings, I have found, give the best results with the PLA at normal temps. It always unloads perfectly, and maybe with the v6 too? Don't have one to try it out on. Prusa Support is straight up the best support team I have ever encountered, and they are very knowledgeable

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

Do you use these settings for all of the nozzles?

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

I’ll have to give these settings a try.

I’ve had some loading problems with the MMU2 in the past but fitting a Revo has inspired me to try harder to fix it.

What temperature are you using for PLA? Does the brand matter? I’m using two colours from the same manufacturer at the moment.

I’m finding it will print for the first 20 layers or so before starting to get load failures and stringy tips.

I’m using the 0.8mm Revo nozzle. This makes for quicker prints. At the moment I’m doing small test pieces but maybe the length of time between changes is too short?

Thanks for your help

J

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

@joe-mcloughlin - in spring post. I’ve been on support for hours with the team and I’m told they can help me. I have mmu2 just installed and decided to install revo6 since my cartridge on v6 ripped off.

I’m unable to get pass z cal for some reason. Filament is feeding in fine. Any idea?? I’m at wits end. Thanks! Goes up and then down as it reaches the bottom i get “Cal failed. Check axes and run again.

Mom, wife, career woman, tinkerer.

RE:

Sorry, haven’t checked this post in a while.

trying to answer all questions.

Do you use these settings for all of the nozzles?

Yes I do, and it seems to work great on all of them besides the .15. I have not tried it on the .15mm yet though, because I can’t find one in stock anywhere.

I’ll have to give these settings a try.

I’ve had some loading problems with the MMU2 in the past but fitting a Revo has inspired me to try harder to fix it.

What temperature are you using for PLA? Does the brand matter? I’m using two colours from the same manufacturer at the moment.I’m finding it will print for the first 20 layers or so before starting to get load failures and stringy tips.

I’m using the 0.8mm Revo nozzle. This makes for quicker prints. At the moment I’m doing small test pieces but maybe the length of time between changes is too short?

Thanks for your help

J

I’m using just the stock prusament pla settings on all filament brands, and if it doesn’t start sticking after a few times I’ll turn the other layers bed temp to 70, which seems to work. I don’t think filament brand matters a ton, prusament, and random Amazon brands seem to all work the same. I haven’t done any huge things on the .8mm yet, but I think that might be a reason that it is not directly supported with the mmu doing color changes. I’ll try soon and let you know though. I have some tiny colors on layers with the .4 but it seems to work fine. I’ll try running that print with the .8 to see.

@joe-mcloughlin - in spring post. I’ve been on support for hours with the team and I’m told they can help me. I have mmu2 just installed and decided to install revo6 since my cartridge on v6 ripped off.

I’m unable to get pass z cal for some reason. Filament is feeding in fine. Any idea?? I’m at wits end. Thanks! Goes up and then down as it reaches the bottom i get “Cal failed. Check axes and run again.

Only thing I can think of is that the pinda probe might not be triggering, so I’d check that it does detect metal, and then see about if the heatsink is fully seated in the extruder body, and make sure that the Bowden tube is feeding it into the tall bit of the nozzle. Is the nozzle hanging too low like it is not screwed in all the way? I’ve found that sometimes filament can get stuck on the threads and it will not thread all the way, then making it lower than the pindas sensing distance, which will throw the error. I think what it could be is that the pinda will not sense the bed and there could be gunk on the z axes that will trigger its emergency end stop that makes it think the nozzle has hit the bed, so check the z axes to make sure there is no gunk on them and that the x carriage easily will go up and down. Final thing, is there any clicking noise when the extender tries to load the filament into the nozzle and do the ramming when it first loads?

RE:

Hello Joe,

Just wanted to say thanks for sharing the settings, used them with my MMU2S which I have never used before adding my revo and it just works with no issues currently.

Only tested with a 0.4mm nozzle and PLA for now.

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

Sigh….. still having problems.

I’ve tried a few different models today, fairly small but with changes from layer 1. I’d say for the first 10-20 layers it changes fine then begins to fail on feeding into the hot end. The tips look reasonable, they maybe are a bit big in diameter (I need to measure a few).

The issue seems to be that the filament gets through the Bondtech gears and then sticks. It makes a juddering noise, I think from the stepper stalling rather than the gears grinding the filament. Maybe it gets through the PTFE and sticks at the heatsink or at the entry to the Revo?

Increasing the spring tension doesn’t seem to help.

A couple of times, as the filament triggered the IR sensor, I squeezed across the Bondtech gears quite hard and it gave a lot more traction to push it through.

Next time it fails, maybe I’ll cool down, take out the Revo and see if it fits.

I’ll have another try tomorrow.

Thanks,

Jason

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

Well, I had a look at the filament tips I cut off yesterday. They are all around 2.10mm in diameter.

The Revo is measuring 2.05mm at the entry. Unsurprising that the tips won’t feed into it. They don’t when cold.

Does anyone have any suggestions on how to solve this?

Thanks again.

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

Did you ever fix this? I just put a Revo on my MMU2S/MK3S+ and no dice either with these settings or the settings I found in another post. The tips are just too big - doesn't matter which filament I try. I've had a problem free MMU for two years - the only thing I switched was the Revo. Kinda bummed, but since I'll have a bambu soon I just may leave it alone. Still.. would be nice to get it working again!

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

Yes, I realized I needed to screw it in more. Not tight but a 1mm or so so it doesn’t hit the build plate. So simple!

Mom, wife, career woman, tinkerer.

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

Not for me….

Last week I fitted some of the NoMBA mods to improve the extruder filament sensor triggering. It seemed to be working much better, I had a couple of prints with only one or two load failures and one with none. All were 3-5 hour prints.

This week, nothing but problems. Load failures every other layer it feels like.

I’m going to try cleaning out and recalibrating both sensors and the hobbed gears.

I’ve not done something daft like got a wrong heatsink in the Revo or something? I am thinking the PTFE ID could be out?

Inconsistency is the most irritating thing with the MMU! I sometimes think I’ve got it sorted and next weekend everything is rubbish again 😡

Thanks for any help!

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

I don't know what it is. My sensors are calibrated - no problems other than the odd fail here and there for two years. All I did was swap in a Revo and now it will get poor tips that stall out. Same as you - it will work for 10-15 swaps and then fail. I tested the tips on a PTFE outside the printer and they were just a tad too big. Same PTFE as before - the settings for this thread did nothing and I found some on another thread, same issue. It's so weird!

RE:

I’m beginning to suspect it’s something to do with the inside diameters of the Revo in the cooling zone. If I remember correctly, the Prusa/MMU hotend has a special heatbreak with different ID to a standard V6.

Could it be that it’s the difference between that and the Revo that means the tips end up a bit bigger and can’t always get into the nozzle?

I’ve not seen detail drawings of both so I can’t decide what I need to do. Maybe changing where in the hotend the tip forming moves take place will help?

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

Others say it works great so not sure. I ran on default settings before this and never messed with any of the settings. I have larger ID PTFE I could use instead, but that won't help the larger tip get through the heatbreak. What's odd is I can do filament swap prints all day long and those tips will work even if I do a second one after the first. I just can't do a regular MMU print.

Hopefully my bambu will get here and then I won't worry about it anymore.

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

Just as a follow-up, I moved my setup to an enclosure and new orientation of parts. This started causing issues but I resolved it by increasing cooling moves to 5 and using stock ramming settings.

Hope this may be of help to someone else.

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

Just an FYI 3/23 I have a new mmu2 running with a Revo and it’s been doing amazingly in stock settings without any adjustments. all 4 nozzles are running perfectly. This combo has solved having to put in custom gcode. It’s rocking, stock!

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

I have just finished building the MMU2S kit for my Prusa Mk3S+, which I have previously installed the Revo on. I have been still running the old firmware on the Prusa, because of problems with the latest firmware and the Revo. Now I just loaded up the firmware for the MMU2 and Prusa and have hit the problem with the Prusa not liking the Revo. Any one know of a cure or workaround? Cheers Mike

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

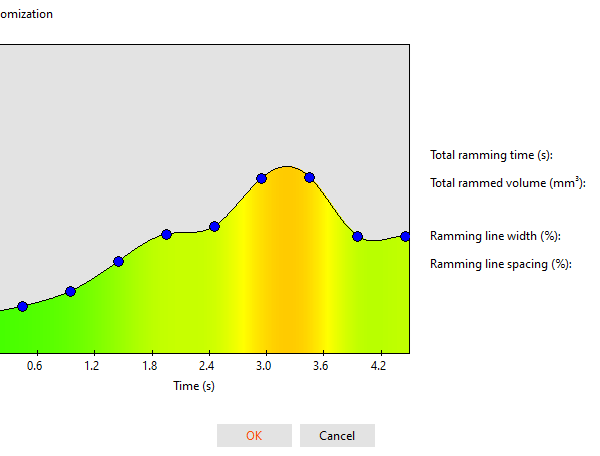

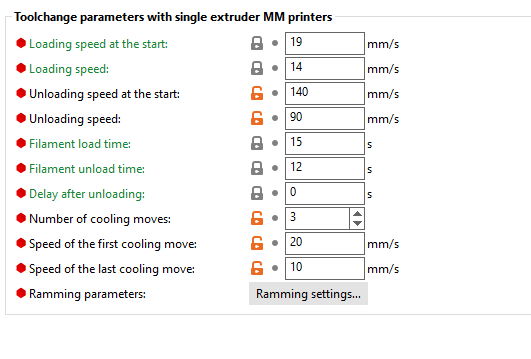

@joe-mcloughlin what are your Single extruder multimaterial parameters?

This is what I have, look ok?

Big thanks to Rodolfo from Prusa Support for all of his help. I had the worst MMU experience with the v6. It literally killed it by somehow carbonizing the PTFE tube in the heatbreak. With the Revo, however, I am getting literal perfect tips. They are perfectly loaded and unloaded from the machine. Again, I talked a few times with Rodolfo on different occasions, and he was amazingly helpful. If Prusa people look at this, he needs a raise after sitting with me, troubleshooting for hours. It finally works, here are his provided settings that just work! I am so happy that this unit finally works consistently for me! These settings, I have found, give the best results with the PLA at normal temps. It always unloads perfectly, and maybe with the v6 too? Don't have one to try it out on. Prusa Support is straight up the best support team I have ever encountered, and they are very knowledgeable

RE: MMU2S With Revo is AMAZING (thanks to prusa support)

For info: I have a Revo 6 and an MMU3 and couldn't get stock settings to work. I have upgraded to Revo-specific firmware 3.13.2 (3.0.1). Using the below settings I get reliable behavior, nice tips, no problems.

For single color prints I can't get the MMU-single color profiles to work, so I load the filament and turn the MMU3 off, and then slice for a standard MK3S+. Works like a charm.

Big thanks to Rodolfo from Prusa Support for all of his help. I had the worst MMU experience with the v6. It literally killed it by somehow carbonizing the PTFE tube in the heatbreak. With the Revo, however, I am getting literal perfect tips. They are perfectly loaded and unloaded from the machine. Again, I talked a few times with Rodolfo on different occasions, and he was amazingly helpful. If Prusa people look at this, he needs a raise after sitting with me, troubleshooting for hours. It finally works, here are his provided settings that just work! I am so happy that this unit finally works consistently for me! These settings, I have found, give the best results with the PLA at normal temps. It always unloads perfectly, and maybe with the v6 too? Don't have one to try it out on. Prusa Support is straight up the best support team I have ever encountered, and they are very knowledgeable