Filament Profiles

Hi everyone,

Is there a repository somewhere where I could find filament profiles other than the ones that come with the PrusaSlicer?

For example, is there a place i can find filament profiles for Sakata or Polymaker filaments ?

RE: No

There is no repository for filament profiles.

--------------------

Chuck H

3D Printer Review Blog

Polymaker print Profiles

I've downloaded some Polymaker print profiles. Format is .ini. Can anyone help me load these files into prusaslicer please? Newbie here. Thanks

RE: Filament Profiles

File > Import > Import Config

Mk3S+,SL1S

RE: Filament Profiles

Thanks, it didn't load the new filament profile into the filament list, is this normal? Is there e a way to do that please?

RE: Filament Profiles

Could you please indicate EXACTLY which one you are trying please. Or preferably zip it up and attach it here.

I downloaded and tried the polymaker polyterra profile they had on their website. They do describe it as a print profile though and that is correct. I started with a MK3 selected for printer, amazon basics pla and a 0.2 speed profile selected. I then used the import config option.

It does load a PRINT Profile that has polyterra in the name. It is not a filament profile as such but it does load in and display a Generic PLA profile that has been modified. It also changed the loaded printer to the first one in my printer list which is a Anycubic Kossel I had imported for testing another issue awhile back. So beware of that too.

Basically this isn't a proper profile designed for distribution at all, it was generated with PS 2.1.0 and I would be a bit cautious of loading and using it. We have seen profiles in the past that when installed basically do weird things like stopping settings changes working as there were duplicate settings in sections they shouldn't have been for example.

They would have been better saving it as a 3mf project file. At least when you load one of those in you can see the profiles selected properly and you can always save any profile loaded in to your presets.

By the way the import config options load in 1 or more profiles (print, filament, printer) depending on what it contains. Once loaded they are temporary, for that session. If you want to keep the settings you have to save them just like saving any other modified profile.

The Import Config Bundle option is different. That imports all the profiles in the bundle and saves to to your profiles lists automatically. When run you get an 'imported XX profiles' message telling you how many it saved.

If Polymaker were serious about supplying profiles for their filaments they would create a bundle for their range that contains just filament profiles and not print or printer ones and make them generic and not locked to a specific vendor.

Creating a customised filament profile is very easy if you have some of the filament to run basic calibration and tests on.

RE: Filament Profiles

I got the same results as @neophyl. It just so happened that I just received my first spool of polysmooth this week and printed with it for the first time yesterday with that profile from their website and it worked fine for me.

Mk3S+,SL1S

RE: Filament Profiles

Here is the one I downloaded from their website.

Mk3S+,SL1S

RE: Filament Profiles

Thanks Neophyl, I had the same results and understood your comments and recommendations. I will build a new filament profile from scratch and keep it that way to avoid any anomalies you mentioned. Cheers!

RE: Filament Profiles

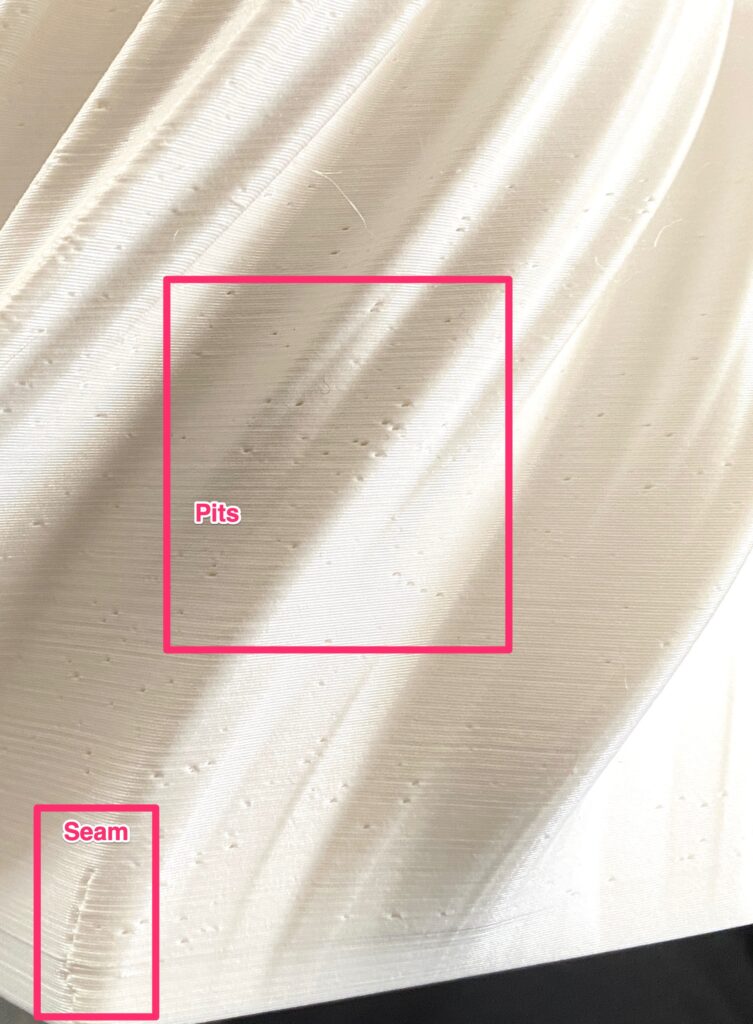

If you could kindly share your profile, or just the settings that required tweaking for PolyTerra, I would greatly appreciate it. I've been struggling with slight under-extrusion (despite many attempts playing with the Extrusion Multiplier etc.), resulting in pits on the outer wall of my print.

RE: Filament Profiles

Who are you making that request to Munkford ?

As it happens I do have some Polyterra in their charcoal black. Got it about 2 weeks ago. Its one of the nicest filaments I've printed with, especially at the price point it sells at. So much so that I've just ordered another 5 rolls as I'm going to run out of this one printing a Pulse Rifle 🙂 and I want more. I think its going to be my go to filament

Some of my filament settings wont be of any use to you as they are specific to my printer. I'm running a modified Mk3 (non s) with a Bunny geared extruder and a steel nozzle x from e3d. I'm also running old firmware that uses the old LA1.0 and not LA1.5 like the new prusa firmware uses. The nozzle itself means all my filament temps are 5-10 degrees higher and I personally print as hot as I can reasonably go as I do a lot of functional prints designed to be handled. Basically if I get angel hair/spiderweb stringing just starting then its hot enough for me 🙂 Quick pass with a butane lighter removes them in seconds so its no hardship.

That being said almost every filament profile I have ALL have an extrusion multiplier of 1.0. I hardly ever have to change it. I just make sure the filament diameter entered matches the real value. In this case I have the diameter of 1.72mm entered in there instead of 1.75mm. I find people adjusting the extrusion multiplier to be a common misconception when they get under extrusion. The very first thing is to accurise the filament diameter to make it match reality. This means the calculations the slicer is doing for volume will be much more accurate.

Once you have that done then you can start tuning things like extrusion multiplier and retraction etc.

Diameter = 1.72 (measure the actual filament though with calipers at various points and get an average)

Extrusion Multiplier = 1

First Layer Temp = 220c

Other Layers Temp = 230c

Bed First Layer = 50c

Bed Other Layers = 53c

Cooling = 80/85%

Bridge Cooling = 100%

Slow Down if layer time below = 6s

Min Speed =5mm/s

Max Volumetric = 10mm/3

That's it really. Just had a scan through all my filaments and generally the only settings I need to change are the diameter, the bed and nozzle temps. At least within a material class. For petg the fan is less of course and the volumetric is higher.

I also mainly print with only 0.6mm retraction enabled and retract on layer change=off, Wipe while retracting=off and I don't need to use avoid cross perimeters. I just don't get major stringing even with my temps on the hot end of the range.

RE: Filament Profiles

Thank you @Neophyl, you seem very qualified to answer this! So far I've found the same; inconsistent filament diameter, needing hotter print temps (220-230), and lower Volumetric. The retraction settings recommended by PolyMaker (on the datasheet) are 1mm Distance and 20mm/s Speed, which is what I was using, but I'm going to try out your recommendation now of 0.6.

My biggest issue has been these pits appearing only on one side/quarter of my print (which is very twisted/swirly by design). These look like under-extrusion but again, only appear on one side/area of a twisty/circular part. The seam I've outlined can be ignored, I'm working around that by switching to Random (this was Rear).

I'll update this thread once I complete my next print, hopefully with better results!

RE: Filament Profiles

You have outlined the seam at the bottom but where is the seam further up ? If the seam was set to rear then Id expect to see a line of them progressing upwards moving around as the closest bit of the model to the back changes. From just the picture my first instinct would have been those are the seam positions.

This is why attaching zipped up project files is so useful and you can quickly look at all sorts of things, slice and preview etc.

If any feature of the slice preview lines up with those gaps (so turn on visualise options for retraction/deretract etc) then that helps narrow it down.

If those gaps aren't linked to the seam position then Id be checking things like the filament tension screw first to make sure its feeding nicely on faster moves just to rule that out. Usually a good idea to rule out the physical before chasing down software ghosts. 🙂

As for manufacturers recommendations, well Id take most of them with a pinch to a bucket of salt. Most filament makers wont actually test on a specific printer as there's far too many out there to check on. So they tend to generalise a bit with what mostly works.

I think that is one reason the Prusa supplied filament profiles are locked down to their printers/vendor space, they will actually test that brand and work out a proper profile on their printers.

RE: Filament Profiles

For example, is there a place i can find filament profiles for Sakata or Polymaker filaments ?

No. There is no repository for filament profiles.

RE: Filament Profiles

I believe reason the seam appears somewhat “random” on the outside when in Rear mode is because there are no straight lines/sharp edges for it to place it on, The entire exterior of the design is swirly/twisted. The inside of the design is a normal cylinder and the inner seam is slight normally (straight line up and down).

I’d normally share a 3MF but this is a commercial design so I can’t. I did preview all the Features in the slicer preview, and most of the pits are Seams indeed. Changing some of the settings you mentioned helped a fair bit as well, so thanks again! Is “filament tension screw” the same one that holds the idler door shut? I did open that recently for a cold pull, closed it setting the screw flush as recommended in the cold pull KB guide.

RE: Filament Profiles

By filament tension screw, yes the one on the idler door. I've occasionally spent hours in the past trying to tweak settings for an issue only to find out that it was hardware causing it. I've got into the habit now of just doing some basic checks on the printer first.

If the pits are retract co-located then you could also try adjusting your retraction speeds. On mine retraction is set to 45 and deretract to 30. I also notice that Bobstro's settings pack is using 50 retraction and 25 deretract as opposed to the prusa defaults of 35/35. Bobstro is pretty good about testing and setting up his stuff and I find it interesting that both of us have settled for a slightly higher retractions and slower deretract.