Problem printing pretty simple items

I have great results printing miniatures, small simple things and stuff like that but when it comes to custom electronic cases, covers, raspberry pi cases geometry is totally messed up.

For example the following cover, it is 100mm by 80mm and 3mm thick, and it get's warped, bottom side where it touches the supports is totally messed up.

I tried multiple orientations, this one is the best but its nowhere near usable.

Is this printer only for toys or can we make functional prints like this one, is it possible or not.

RE: Problem printing pretty simple items

Hi,

I have noticed the same problem - all flat surfaces of the bed are hard to get right.

I'm still only working on the first bottle of orange resin that came with the printer, but I have done a did a bit of testing.

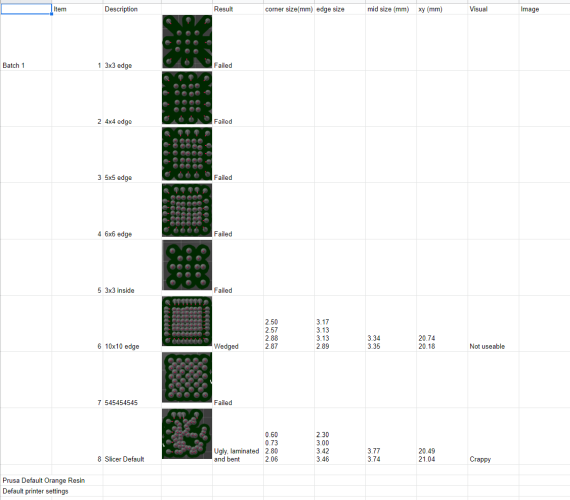

I printed two batches of 8 20x20mm squares of 3 mm thickness.

In the first batch only 2 survived and looked pretty badly.

Second batch showed better results, but still not to great. The only way to success seemed to be 1.5mm spacing aka pretty excessive supports. Low res images of the result below as well as link to the original google sheet I made.

Planning to review the influence of layer heights etc. when I get the time.

/Lars

RE: Problem printing pretty simple items

Instead of using supports under the part, you can also try and print on the bed direct and put support on the side. Its a function in slicer you can select.

Ron

RE: Problem printing pretty simple items

@dario-f

I guess, your model to be printed horizontally directly on the bed is to large to get inside of your SL1 container, isn´t it?

Unfortunately the gravitation works also inside the container and taking in account that the during printing the model is still not fully solid, so the gravitation influences it rather significantly. I guess to balance the gravitation is possible only in way how you did in your second post. You could try vertical print using only supports of the first layer ,but I am not sure if you will not face adhesion issues.

to print boxes of shape/size you indicated above I guess the new Prusa MINI can be a suitable solution. When you will print more of them it will also become at the end even cheaper 😉

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect