1.7.0-beta.4 Firmware for SL1 & SL1S

Greetings all, just in time for the weekend we are pleased to announce a new beta firmware for our SL1 and SL1S SLA printers. Please find all the details below.

Summary

- Resin tank cleaning feature

- Improved resin calibration

- Print profile for high viscosity resins

- Improved behavior of the resin sensor

- Added option to cancel preprint checks

- OS version updated

- PrusaLink updated

- Bug fixes

- Known issues

This is the first public beta release of the upcoming firmware 1.7.0, which brings two new important features. Compared to the previous release 1.6.4, there are 24 bug fixes and 105 pull requests. Please note that this firmware is recommended to the advanced users.

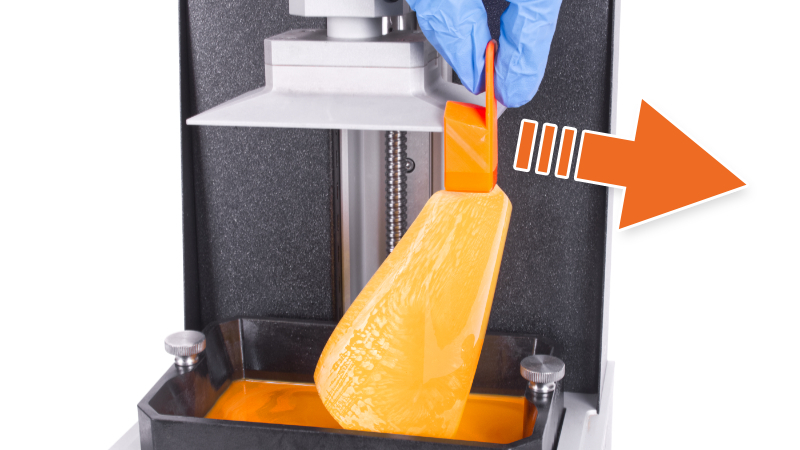

Resin tank cleaning feature

Once a print is finished, there might be enough resin in the tank to start another print immediately. However, there might be small parts laying at the bottom, invisible to the naked eye. Upon starting the next print, the print platform can push these parts against the FEP film and punch holes in it. For this reason, we recommend pouring the resin back into an empty bottle through a sieve and only then reusing the resin.

We are fully aware that this approach takes more time and this is why we are now testing a feature called “Resin tank cleaning”. When the print is finished, you can select this feature from the “finished” screen. Insert a special 3D printable adapter on the platform, wait while the printer lowers the platform and cures the first layer at the bottom of the tank (adjustable for 30-120 s). Once the curing is done, the platform rises up along with a thin layer of exposed resin attached to it.

IMPORTANT: Though this feature was heavily tested, it is not fully finished yet. While cleaning the tank, please always pay close attention to the printer to avoid possible issues. To learn more about this new feature, please see article Resin Tank cleaning.

Improved resin calibration

Even though we are constantly testing new resins and creating tailored print profiles, we are unable to cover all resins available to the market. With this release, we are bringing an option to run a calibration print, which will print multiple objects at different exposure times to help you decide, which value is the best for your resin.

During internal testing, we have discovered that the feature requires a major overhaul and this is why we have significantly updated the code and further extended its capabilities. Now, the printer is properly utilizing the HW acceleration to achieve improved precision and reliability.

The calibration object is now provided in three variants with different layer heights (0.025, 0.05 and 0.1 mm). To learn more about resin calibration please visit article Resin Calibration.

Print profile for high viscosity resins

The main aim of SL1S was to push the boundaries and increase the speed of SLA prints, in some cases the overall time is only 25 % of the previous generation SL1. However, in some cases, this speed is too high.

One example is professional resins with high viscosity. The SL1S in its default setting moves too fast and the resin is unable to flow and spread evenly under the print platform. Since this is a physical property of the material and can't be changed, we are adding another option “High Viscosity” to already existing profiles “Faster” and “Slower”.

Resin sensor improved behavior

Previously, when the resin sensor failed, the system halted with an error. Now the printer repeats the action two more times before reporting an error. We would like to thank the users who suggested this change.

Canceling preprint checks

Until now, when the pre-print checks were running, the user wasn't able to cancel them. From our experience, you might realize you haven't prepared the printer properly and the checks will inevitably fail. For this reason, we are now adding an option to cancel the checks at any time and return back to the menu.

PrusaLink updated

The overall look of the web interface PrusaLink is now unified across our printers (FDM/SLA). Sidebar parameters include the status of the printer. Also, starting this release, users can also download the project from a remote URL directly into the printer.

OS version updated

The SL1 and SL1S are based on a forked version of Debian Linux and as a part of regular maintenance, the developers have updated this part of the system. Yocto version 3.1 Dunfell was replaced by 3.4 Honister. This means Linux kernel 5.15 is used instead of 5.11. The new version brings improved performance and security.

Bug fixes

- The web user interface PrusaLink could freeze when attempting to print on an uncalibrated printer. Now, the printer recognizes the uncalibrated state and asks the user to perform it first.

- In certain situations, the logic of automated fan speed control was not disabled during fan tests. This could have resulted in an incorrectly failed test. The algorithm was adjusted to work correctly.

- Incorrect (less than a minute) print time was sometimes reported by the printer after the auto switch-off was switched on again.

- After changing the language of the user interface, the printer had to be restarted for month names to reflect the change. This was fixed, the language change propagated instantly.

- The LED test was not carried out before printer calibration. Devs have corrected the order of tests for this release.

- In the “Printer calibration tilt adjust” screen, the OK button was incorrectly shifted and cropped for Spanish, French and Italian. Now, it is displayed correctly.

- Project previews of the files uploaded by Prusa Link were sometimes not displayed. The issue was detected and corrected.

- The QR codes in the “About us” screen were pointing to the English web page even when the printer was set to another language. Now, the URL link in the QR code is changed correctly based on the selected system language.

- After a certain rare sequence of upgrades, slot swaps and failed calibrations it was possible to start printing on an uncalibrated printer.

- Security and network tokens are remembered after firmware upgrades. Prior to this fix, they had to be re-entered after each upgrade.

- PrusaLink now handles files with respect to filename extensions correctly. Before it was possible to initiate the upload of files that were incompatible with the printer model.

- The printer's “Hostname” is now being checked for correct format while entered by the user.

Known issues

- The system may not correctly distinguish and report the difference between a homing error and a resin sensor error during resin level measurement.

- Texts in GUI and PrusaLink are not fully reviewed and translated to all languages for this beta release.

Download location;

https://github.com/prusa3d/Prusa-Firmware-SL1/releases/tag/1.7.0-beta.4

Firmware update instructions;

https://help.prusa3d.com/en/article/firmware-updating-sl1-sl1s_124776

Shane (AKA FromPrusa)

RE: 1.7.0-beta.4 Firmware for SL1 & SL1S

What is the difference between slow, and high viscosity presets? Is the high viscosity basically “extra slow” mode?

RE: 1.7.0-beta.4 Firmware for SL1 & SL1S

I updated and am now stuck in the starting screen. See attached photo

RE: 1.7.0-beta.4 Firmware for SL1 & SL1S

Beta version doesn't work, see this thread.