Tilt tray making bang noise and not going down

Hey guys,

It's happened a few times but tonight it's continually doing this, when the tray is supposed to tilt down it makes a sound like it's stuck but then slowly goes down in small steps l, lifts up fine then bang and repeats. It's now making two fast bang noises at the time of tilt. It doesn't do this through the whole print but maybe from layer 20 to 50 give or take... The model is the same thing I've been printing for days now so I don't think it's too do with that. Here's a video.

https://youtube.com/shorts/fZUQO9pJtIc?feature=share

I just recorded another video of it doing the double bang but it's the same thing just struggling a bit more...

I'll email support but wanted to see if anyone has had this before first

Cheers.

Mitch

RE:

Hi, I had the exact same issue. And I solved it by turning tilt speed just before start of the print to slower setting. From my point of view it depends on the model (are there big closed holes at the bottom of the model?) or if the model is hollow.

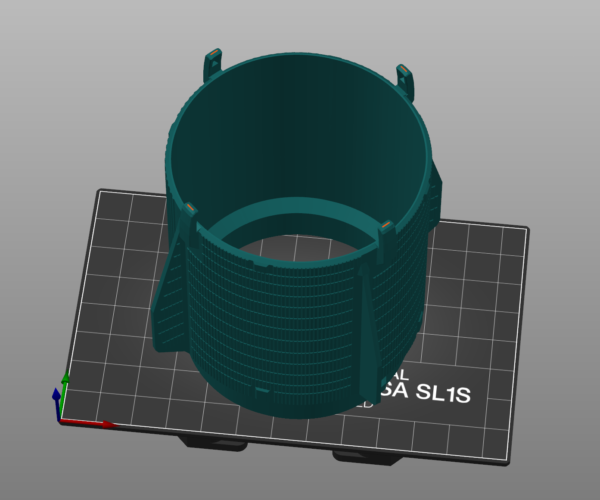

If you are trying print big hollow model or someting like this (my case):

then the tilt speed is so fast (1.8s in my case) that the resin does not manage to flow into the enlarging hole and in time the vacuum pressure is building up which then leads to that terrible sound and temporarily stopping of the resin tray tilt.

I can think of this solutions:

- As mentioned above, lowering tilt speed to slower solves the problem but also slowing print speed drastically. But I was ok with it.

- Probably another resin with lower viscosity should do better - I didn't tried this because I don't have another resin at the moment (I was printing with Prusament Resin Tough Sandstone Model).

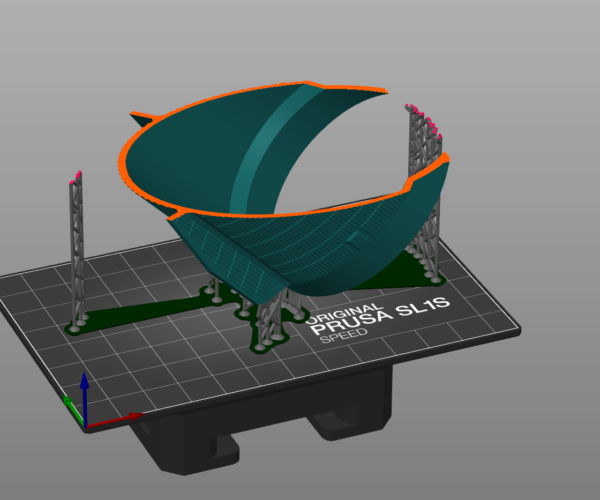

- Rotating the model and using supports so there won't be any big closed holes at the begining of the print, something like this (image is just for understanging what i have in mind, in reality it will probably need much more supports):

- Creating at least 2 side holes on the bottom part of the model. This can be undesirable. I didn't tried it but should be solution too.

- Hardware solution would be platform with holes but at the moment this doesn't exist.

There may be more solutions but that's all I can think of at the moment.

Hope this helps.

RE: Tilt tray making bang noise and not going down

I'm having this issue as well but when printing the official Resin Vat Cleaner adapter ( https://www.printables.com/model/153276-resin-tank-cleaning-adapter/files)

When it switches to fast tilting the problems begin and usually it ends up with the part detaching from the build plate and instead sticks to the FEP film.

Seems like it shouldn't be a slicer problem since there's a pre-sliced file (with which I have the same issue). I know it's been a long time but were you able to solve this with the support or did any of the tips mentioned by the above poster help?