RE: Frequent clogging with Verbatim BVOH

@ssill2

Yay! That is awesome! Glad it is working for you!

I have dried my BVOH and my PLA that I was using. It wasn't quite working after that but definitely made a difference.

I have run a bunch of tests and have determined my most cooperative PLA and MMU2S lane. Now, I am using the best PLA with the best lane and doing a "Purge Test". The test is just increasing the purge amounts after loading PLA in increments of 70mm^3 starting from the default which is also 70mm^3.

I wish I had started this MMU2S journey by doing well thought out tests that only change one thing at a time. I must admit, I was impatient before and had been changing things too erratically and not putting enough thought into what I was changing and why.

Definitely have seen an improvement. I hope it continues through the remainder of my tests and that soon, I will be printing a model!

RE: Frequent clogging with Verbatim BVOH

After all this discussion, i’ve decided to print anything with soluble interface, to check firmware, settings and everything.

my conclusion:

my prusa has just one modification:

the ptfe tubes has an inner diameter of 3mm

i have printed this with standard filament settings, with this modifications:

Filament temperature 205

Later start: random

pva extrusion multiplier 1.05

purge distance 150 (i think it is too much)

And from the printer knob, speed in 48% to reduce oozing and avoid pva to interfere between layers of pla.

this finished with 3 load errors in mmu, wich needed intervention

my conclusion:

it us all about of take care to small details like:

dryed pva

correct alignment of mmu2 pulleys (strict alignment)

correct calibration of pinda and finda (strict calibration)

correct alignment of ptfe tube in ptfe tube quick release connector

tension in extruder idler just enough to push filament, not too loose to cause stripping, not too tight to cause jams.

but my silver bullet:

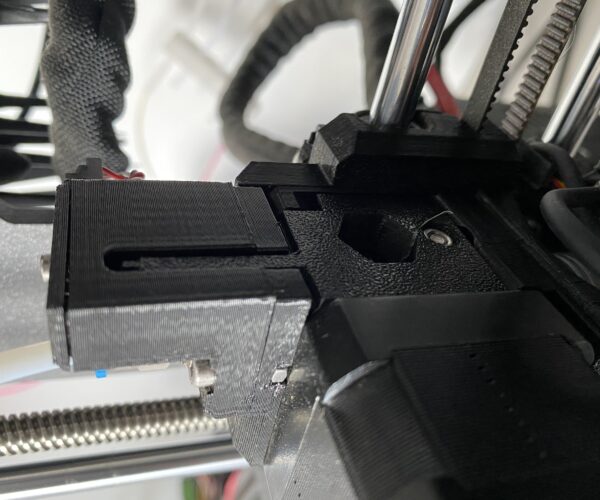

release the screws from ir sensor turret and re align the turret pushing to the right as much as possible

RE: Frequent clogging with Verbatim BVOH

@mdjuan

I did the 3mm ID tube thing. I hate more issues getting the darned filament to load in the first place. I ended up going back to the 2mm ID tubes. Which do tend to work well.

I 100% agree that correct alignment of the filaments across the idler gears in the mmu is very important. I never went with the stock ptfe tube pass-thru on the back of the MMU. it was advised to me that I do the festo-connectored one and that has worked like a champ along with making the tubes easier to replace.

I also agree that a correctly calibrated finda and ir sensor are crucial. The last thing for me was that idler screw tension on the extruder itself. Since then my filament load issues are pretty infrequent.

RE: Frequent clogging with Verbatim BVOH

I found filament also plays a huge role. I am using all Prusament PLA but ran 4 tests yesterday that rotated my 4 most-used PLAs through lanes 1-4. I found that my Prusament PLA Lime Green Blend had 0 failures in 56 loads (14 loads from each of lane 1, 2, 3, and 4) while my Prusament PLA Pearl Mouse had 20 failures in 56 loads under the same conditions.

I was very excited to find this and hoped it would mean that switching my 2 colour print (PLA + BVOH) so that it used the green filament would fix or at least reduce my problems. It did not. I'm trying to decide on how I can test my idler to find the perfect tension for it.

RE: Frequent clogging with Verbatim BVOH

GUYS! I'm so happy! I figured it out! It was such a simple mistake that basically rendered my machine useless!

I was perusing forums and found someone saying that a common mistake with the MMU2S is installing a PTFE tube in the hotend with a 2.00mm inner diameter. If you are using the MMU2S, the hotend's PTFE tube should have a 1.85mm inner diameter!

I had previously upgraded my extruder to a Bondtech one, and the kit comes with a 2.00mm inner diameter PTFE tube. Not remembering the aforementioned detail, having added the MMU2S over a year ago, I built the extruder with the supplied tubing without thinking for a second that it could be wrong. I found some spare PTFE tubes with the correct inner diameter and cut it to the correct size for my extruder. I replaced the tube, re-assembled, calibrated, and pressed play on the test print I had been trying to do.

It worked with ZERO issues!

TLDR; My extensive loading issues (failed on 30-50% of loads) with my MK3S and MMU2S with Bondtech extruder upgrade and Mosquito hotend upgrade were all because I was using a PTFE tube in the extruder with 2.00 inner diameter. Replacing it with a tube with a 1.85mm inner diameter instantly solved the problem.

RE: Frequent clogging with Verbatim BVOH

@karalt

great news!

RE: Frequent clogging with Verbatim BVOH

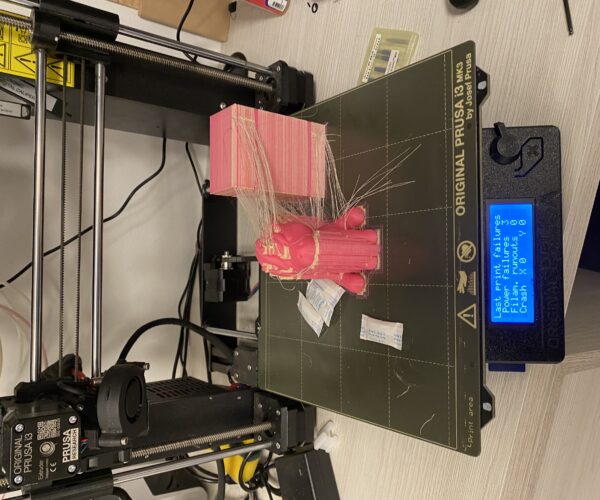

@mdjuan

Looks like success to me. Good job!

RE: Frequent clogging with Verbatim BVOH

1. Dry the BVOH at 60deg Celsius in a filament dryer for 10 hours before printing.

2. Keep the BVOH at 30-40deg Celsius in a filament dryer during the entire print (if longer than 36 hours).

****If the exterior of the BVOH absorbs any moisture, the pulley tears away at the outer layer and leaves BVOH dust on the pulley causing it to slip. Also the tip can become stringy upon retraction**

**Some people argue that the drybox is the solution, but if the BVOH goes in moist, it stays moist; I have no experimentation with the drybox**

3. Set your Max Volumetric Flow for the filament (not the overall MVF) at 2.03 mm^3/s for a .4mm nozzle with a .15mm layer height. (Layer height times layer width times print speed which Verbatim recommends at 30 mm/s print speed)

4. Set your total ramming time for BVOH to 4.5 seconds, number of cooling moves to 4, speed of first cooling move to 20mm/s, speed of last cooling move to 10 mm/s, loading speed at start to 19 mm/s, loading speed 14 mm/s, unloading speed at the start 140mm/s, unloading speed 90 mm/s, filament load time 15 s, filament unload time 12s, delay after unloading 0s. Ramming parameters change the shape of the tip when retracted. If the tip has poor shape and a long string, the loading of BVOH is negatively affected as well as the loading of any other filament because the strings break off in the ball of the Super FINDA and cause the ball to remain stuck in the up position.

5. Set the Retraction length for BVOH to 3mm and the retraction speed for BVOH to 50 mm/s. Retraction parameters affect stringiness between regions on the print bed.

6. Print with Prusament PLA or Prusament PETG or a known good filament with known good parameters to ensure you are only in need of adjusting the BVOH settings.

7. Set your purging volumes for BVOH to 120mm^3 on the unload and 120 mm^3 on the load to ensure no BVOH remains in the nozzle during the printing of the desired solid regions.

8. Set the bed temperature to the same as the filament you are using. BVOH has the same recommended bed temperature as PLA but if you are printing BVOH with PETG, set the BVOH bed temperature the same as the PETG but do not allow the BVOH to be printed directly on the print bed by using rafts, brim, or soluble interface.

9. There are many other settings that should be experimented with: No sparse layers, Overhang Threshold, Overall max volumetric speed to name a few. But you assembled this thing (MMU) yourself, so you should have realized then that there's going to be a bit of "figuring out"

**The aforementioned settings are for prints that require the highest quality and takes upwards of 70 hours to print and are just some suggestions to get you thinking about your requirements*

RE: Frequent clogging with Verbatim BVOH

Just replying so I can remember this post and thread when I need to use BVOH! 🤣

1. Dry the BVOH at 60deg Celsius in a filament dryer for 10 hours before printing.

2. Keep the BVOH at 30-40deg Celsius in a filament dryer during the entire print (if longer than 36 hours).

****If the exterior of the BVOH absorbs any moisture, the pulley tears away at the outer layer and leaves BVOH dust on the pulley causing it to slip. Also the tip can become stringy upon retraction**

**Some people argue that the drybox is the solution, but if the BVOH goes in moist, it stays moist; I have no experimentation with the drybox**

3. Set your Max Volumetric Flow for the filament (not the overall MVF) at 2.03 mm^3/s for a .4mm nozzle with a .15mm layer height. (Layer height times layer width times print speed which Verbatim recommends at 30 mm/s print speed)

4. Set your total ramming time for BVOH to 4.5 seconds, number of cooling moves to 4, speed of first cooling move to 20mm/s, speed of last cooling move to 10 mm/s, loading speed at start to 19 mm/s, loading speed 14 mm/s, unloading speed at the start 140mm/s, unloading speed 90 mm/s, filament load time 15 s, filament unload time 12s, delay after unloading 0s. Ramming parameters change the shape of the tip when retracted. If the tip has poor shape and a long string, the loading of BVOH is negatively affected as well as the loading of any other filament because the strings break off in the ball of the Super FINDA and cause the ball to remain stuck in the up position.

5. Set the Retraction length for BVOH to 3mm and the retraction speed for BVOH to 50 mm/s. Retraction parameters affect stringiness between regions on the print bed.

6. Print with Prusament PLA or Prusament PETG or a known good filament with known good parameters to ensure you are only in need of adjusting the BVOH settings.

7. Set your purging volumes for BVOH to 120mm^3 on the unload and 120 mm^3 on the load to ensure no BVOH remains in the nozzle during the printing of the desired solid regions.

8. Set the bed temperature to the same as the filament you are using. BVOH has the same recommended bed temperature as PLA but if you are printing BVOH with PETG, set the BVOH bed temperature the same as the PETG but do not allow the BVOH to be printed directly on the print bed by using rafts, brim, or soluble interface.

9. There are many other settings that should be experimented with: No sparse layers, Overhang Threshold, Overall max volumetric speed to name a few. But you assembled this thing (MMU) yourself, so you should have realized then that there's going to be a bit of "figuring out"

**The aforementioned settings are for prints that require the highest quality and takes upwards of 70 hours to print and are just some suggestions to get you thinking about your requirements*