ALERT! Filament Sensor shifts out of calibration due to printing in Enclosure.

I printed a number of sketches for a clutch master cylinder out of ASA using BVOH as supports prior to printing some out of carbon fiber.

The master cylinder on the right is the broken one out of cast Beryllium and the one on the left is the sketch printed with ASA for a test assembly before I print it out of carbon fiber.

After four or five various prints (not all the same object), I began getting failed loading of the BVOH and sometimes the ASA, and consequently a number of consecutive failed prints. What struck me as odd was that the failed loading was occurring at the extruder and not at the MMU where I would have expected a slippage from possibly two much moisture in the BVOH (it was raining that day).

After some serious searching and work unclogging the extruder (which by the way is very difficult without disassembling the extruder), I ran some simple tests with a drawing that changed between the ASA and the BVOH while watching the Sensor Info Screen.

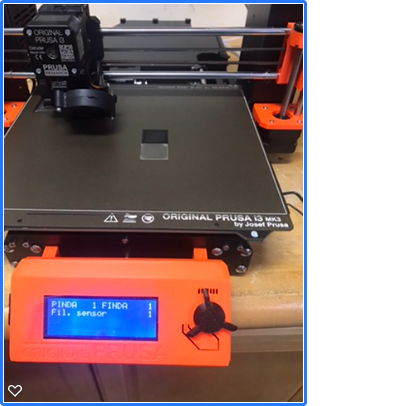

What I found was that the Filament Sensor was flickering between 0 and 1 during the print (if it even loaded the filament at all).

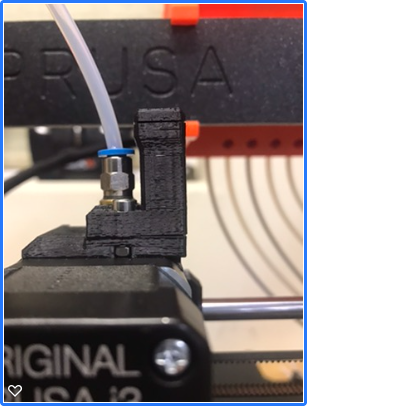

I found it very difficult to calibrate the filament sensor. The reason being is that the filament sensor housing had bent ever so slighty to the left.

On the bottom right, you can see the small gap between the filament sensor housing and the extruder causing the filament sensor to be positioned very slightly to the left and out of adjustment. I believe this small warpage of the filament sensor housing was due to the temperature inside the enclosure. I recalibrated the filament sensor and it works fine again, but I'm not sure if it will bend even further.

RE:

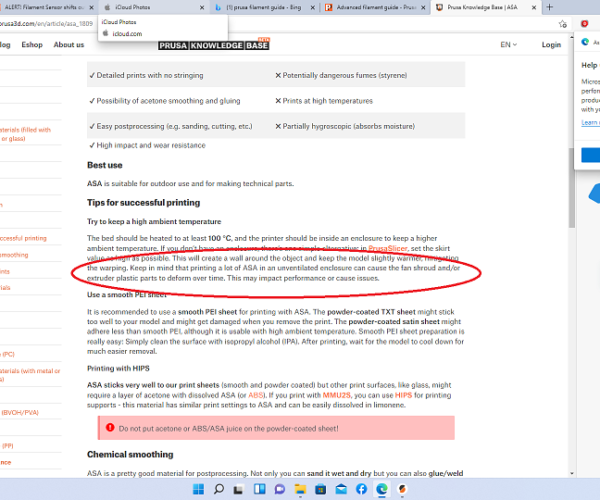

In Prusa's Advanced Filament Guide under ASA it states that plastic extruder parts and fan shroud can deform over time when printing ASA in an unventilated enclosure.

What they mean to say is you're screwed if you do this!

I had the enclosure but no ventilation, so now I have to rebuild the extruder. I'm sorry to bring you all such sad news.

RE: ALERT! Filament Sensor shifts out of calibration due to printing in Enclosure.

Thank you for your posts, this and Printing ASA with BVOH soluble support material has been very insightful for me, I'm looking into printing ASA with BVOH using the MMU2S for my business.

Other users seem to have a hell of a time with the MMU2S, I'm curious if your unit required tinkering and what your overall opinion is on it? Also how has the support support scarring been on the bottom, has the BVOH has any issues adhering to the ASA?

RE: ALERT! Filament Sensor shifts out of calibration due to printing in Enclosure.

Also, what type of an enclosure are you working with?

RE: ALERT! Filament Sensor shifts out of calibration due to printing in Enclosure.

BVOH has no problem sticking to ASA (or actually the ASA has no problem sticking to BVOH). If you print in a heated enclosure (65 degrees Celsius) as you will find necessary to print ASA without warping, you will find the BVOH turns into a soft noodle just going down the tube to the extruder while printing in a heated enclosure and causes tremendous problems. Also, the BVOH jams the extruder when printing above 220 degrees Celsius (once again, it just gets too soft). The ASA is being printed at 260degC and the BVOH at 220 degC, and sometimes the remaining ASA has trouble being purged at the lower temperature. But the real problem is the BVOH turning very soft when the enclosure is hot; it slips in the drive pulleys. You will absolutely be maddened at the process.

I've been very successful printing ASA with HIPS supports, but the solvent (D-Limonene) can also damage the ASA if soaked for too long (I've only read it is for printing ABS and only certain manufacturer's ABS at that). The solvent will cause the whole print to delaminate at the print layers (I have read that this is true for some manufacturers ASA and ABS). To print with ASA consistently it is mandatory to have a heated enclosure, and that causes the stock extruder and other parts to warp so they first must be printed with polycarbonate and replaced. After all that, the HIPS only mentions being used as support material for ABS printing, which is very similar to ASA.

Here is a successful ASA print with HIPS, but it is a mistake: the HIPS is so messy when dissolved! I would have been better off printing using soluble interface instead of soluble full supports. Also the material should have been ABS, because I found out later that the ASA brand I used couldn't hold together when submerged in the D-Limonene. But if I break as much off as possible and soak the print for small amounts of time I can clean off the HIPS.

To summarize: it's hard and takes considerable effort in preparation for these prints.

RE: ALERT! Filament Sensor shifts out of calibration due to printing in Enclosure.

Interesting, thank you so much for the feedback. I'm looking to get a MMU2S currently, once I get the unit I'll try out your setup/mods and reply with my findings. Thank you for the time!!