Lessons learned about the MMU2S so far.

A few lessons I learned about the MMU2S so far.

When I first installed the MMU2s with new parts it worked fine. Over time it had problems and I have had to do a few fixes.

1. The idler being attached to the servo motor tightly is critical. The instructions to tighten the 2 bolts, but don't break the idler causes problems. People break the idler or don't get it tight enough. There are a few versions of a stonger idler in the model files.

There is no "locking" mechanism to keep the 2 bolts tight that connect the idler to the servo motor. In my case I tightened the bolts without cracking the idler, but over time they came loose. The idler would not index correctly and there was chaos. The hole for the servo shaft in the idler got worn from the bolts coming loose. I printed a new stronger idler to replace the original. This time I also used a product called "Loctite threadlocker Blue 242". This helps lock the bolt so it doesn't come loose. I applied it to the bolts and then tightened them down. So far so good.

2. The feeder on the hot end has to be set to work flawlessly. Over time I have had to do a few upgrades to make it more reliable. I have used the mod to add brass Bushings to the idler and the one to allow putting the PTRE tube all the way in almost to the gripping gears. See make comments for details.

3. Some colors and materials work better than others on loads 2-n times to the hot end. The streamers or big ball ends made when extracting may cause problems. This is ongoing for me and many others I think.

When there are multiple problems it seems like chaos. As I worked through the problems reliability is back up to "new" status.

For a lower cost multi material handler it is now working well. To have 100% reliability printing multiple colors I think PRUSA has already shown us the best answer, the multiple heads and head changer in the new XL design.

RE: Lessons learned about the MMU2S so far.

I would also suggest a few relatively easy modifications to make life with the MMU2S more tolerable ...

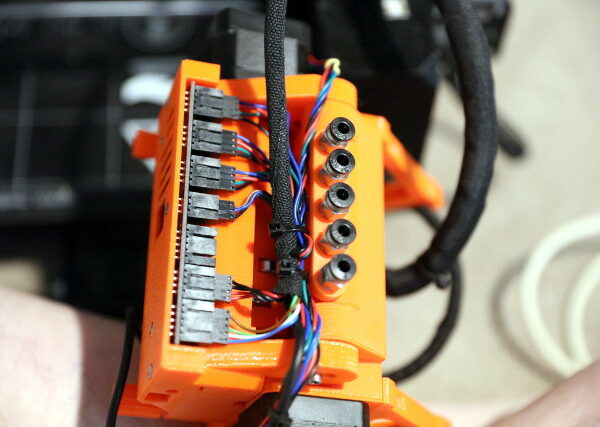

1. Bowden fittings on a remixed manifold. Remixed print is (was?) in the Printables section. No more futzing around with the clamp-type manifold.

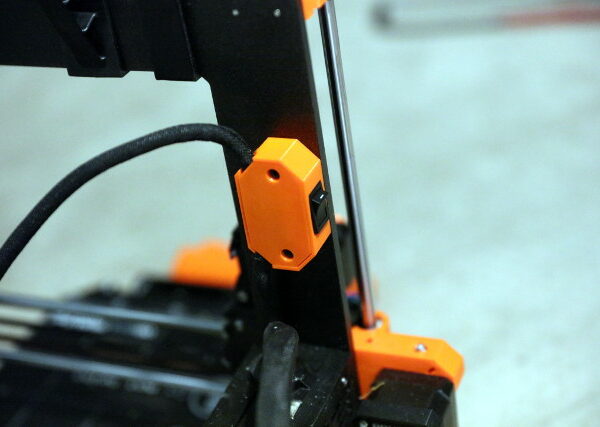

2. DPST switch to disconnect the power from the MMU2S when using the printer as a plain old MK3S series printer. The little switch enclosure is (was?) in the Printables section as well. There are two tapped screw holes on the frame that look like they were almost intended for something like this.

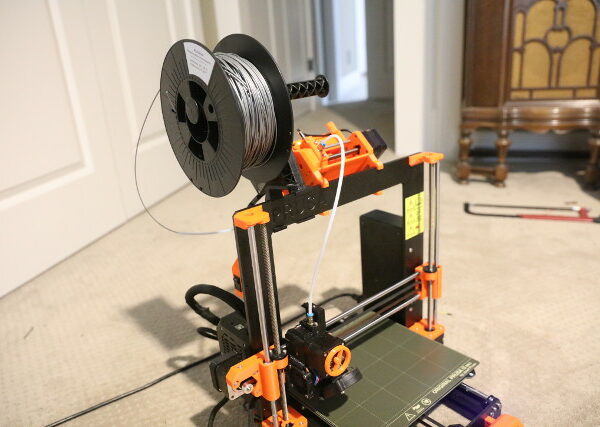

3. Those extended knurled knobs to control the tension. (Barely visible in third photo.) MUCH easier to open it up or adjust the tension.