RE: MMU2S filament tips on unload

Thank you for posting such a clear set of notes. I was getting frustrated with the difficulty in finding good data, too.

Your settings have made a big improvement over my tips, and I am no longer getting the long strings what were causing jams and misloads.

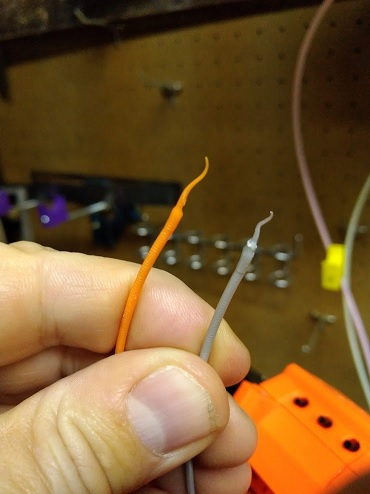

I am still getting elongated ends, and not the crisp, nearly round ends that Prusa shows in the guides. (See picture).

However, my test prints are coming out fine, based on ~100 filament changes so far.

Any advice on additional setting changes? Or should I just leave it alone and be happy it works.

Prusa I3 MK3S with MMU2S. No mods

Hatchbox PLA (4 colors) and eSun (1 color)

Hot end 180 C (I know this is ridiculously low, but it worked).

Per your notes:

Unloading speed at the start: 140mm/s

Unloading speed: 90mm/s

Number of cooling moves: 3

Speed of the first cooling move: 20mm/s

Speed of the last cooling move: 10 mm/s

Ramming parameters: Total ramming time(s): 4.50

RE: MMU2S filament tips on unload

@jeffrey-r10

ok, never thought tips could get that bad. you are lucky that these find the way through your extruder 🙂 Mine usually look like yours without that tail (quite thick), but never that stringy (I am using mainly Fillamentum and Noulei, but other brands show the same). How does Hatchbox look like at 210 °C? Have you ever tried Fillamentum?

These tips look as if you will get lots of problems on the longer run with debris in your extruder causing the IR sensor to give false positives.

RE: MMU2S filament tips on unload

@michael-t66

I know. Those tips are pretty ugly. But, like I said, it seems to work without jamming.

Based on your question, I've started a test print at 210 C; the tips don't really look much different, except the eSun filament has some long threads. No jamming after 10 tool changes, so I'm keeping my fingers crossed.

I have not tried Fillamentum filament. I moved exclusively to Hatchbox about a year ago, and until now I was very happy with quality and consistency. I'm going to experiment with some leftover AmazonBasic and Ziro PLA over the weekend. And maybe try some old ABS. Based on some other threads, I assume PETG is going to be worse.

RE: MMU2S filament tips on unload

update: printing PLA at 210 caused a jam (the eSun filament started producing threads again). Switching back to 185 gets rid of the jams.

I experimented with ABS, and got the same tip shape. This surprised me, since the forums suggested that filament tips with ABS would be better than PLA.

Could it be some kind of gap in my extruder heat break? I saw some posts suggesting this. Again, I'm reluctant to do a major disassembly if it is unlikely to make it better.

RE: MMU2S filament tips on unload

I'm having a similar problem with the tips right now on my MK2.5S with MMU2S. I'm trying to print with Prusa PLA white and Prusament Silver PLA. With the original settings for ramming etc. the tips look quite ok but they are to thick to be reinserted into the hot end. Every time the filament is reaching the hotend, extruder is grapping the filament and starts to insert, and then all of a sudden filament is stucking and the extruder is rejecting the filament. The printer is trying that 3 times and then one has to correct the problem manually.

Changing the initial unloading speed to 120 did not really help allthough they improved the tips (but not enough).

The strange thing is that if I print in single extruder mode and the filament is ejected after print is finished (or if I cancel a print), the tip looks perfect! I have never had any problems with the tips in single mode. It seems that the printer is using a different sequence in such cases. Does anybody have an idea which settings are used in such cases. I would like to copy them for the multi-material mode. Maybe that solves my problems.

For Verbatim BVOH the standard settings in Slicer work for me - there I have no problem with the tip thickness. Strange world!

RE: MMU2S filament tips on unload

I have the same problems as oliver-r4 here, always such bad strining tips that maybe only 4 filament change is possible :(.

Mk3S + MMU2S

OctoPrint 1.3.12

and I only use PETG Prusament in different colors.

So please point us in the right direction. Single print was never a problem. Multicolor ist hell!

RE: MMU2S filament tips on unload

@oliver-r4

You need to check your IR sensor on the extruder. Best would be to solder a LED on it. The display won't show you all. If it retries it has or has not detected something (IR sensor calibration badly needed). If it cannot load because of a fat tip it just grinds. See lots of posts for that mod. 5 minutes and done.

RE: MMU2S filament tips on unload

@bestellung

PETG? Which temperature? With PETG I personally go for 230-235 °C because of the stringing. If it is just for the stringing lower temps are better. If your problem is something different temps won't help. An open idler door and an open selector helps quite a lot for stringing.

RE: MMU2S filament tips on unload

@jeffrey-r10

Again, this is heat creep and nothing else. Your extruder is too warm. An active cooling will help. Alternatively use a PC 140 mm fan and place it next to the bead pointing at the extruder. You will see the difference.

RE: MMU2S filament tips on unload

@michael-t66

my IR sensor works perfect in my opinion. The extruder graps the filament and pushes it into the hotend. According to this post here: https://github.com/prusa3d/Prusa-Firmware/issues/1689 the extruder pushes the filament 50 mm in and then 45 mm out. But shortly before the filament reaches the 50 mm (I guess its the point where the PTFE-tube ends and the heatbreak starts) the filament stacks. One can hear that by the extruder gears. And there the IR sensor detects it and filament gets unloaded again. So the sensor works like it should. But the LED is a very good idea which I have on my list already for a while.

What I still do not understand is that the tips are perfect if the printer is working in single mode (with MMU). Therefore I compared the ejection procedure of the filament in single mode and MM mode for the same filament. And they are completely different!

For single mode I got this code:

G1 E2 F5000 ; ramming equivalent?

G1 E2 F5500 ; ramming equivalent?

G1 E2 F6000 ; ramming equivalent?

G1 E-15.0000 F5800 ; push back

G1 E-20.0000 F5500 ; push back

G1 E10.0000 F3000 ; cooling

G1 E-10.0000 F3100 ; cooling

G1 E10.0000 F3150 ; cooling

G1 E-10.0000 F3250 ; cooling

G1 E10.0000 F3300 ; cooling

M702 C ;eject

So the filament is pushed back 35mm in total and then pushed back 10 mm in , 10 mm out, 10 in, 10 out and again 10 mm in. After that the filament is finally removed from the extruder.

The according code in MM mode (without the ramming sequence):

G1 E-15.0000 F8400

G1 E-24.5000 F1200

G1 E-7.0000 F600

G1 E-3.5000 F360

G1 Y151.860

G1 X170.750 E20.0000 F454

G1 X221.180 E-20.0000 F403

G1 X170.750 E20.0000 F353

G1 X221.180 E-20.0000 F303

G1 E-35.0000 F2000

The filament is pushed back 49.5 mm in 4 steps with decreasing speed. It starts with the "unloading speed at start", continues with the "unloading speed" and goes down to much lower value than the "unloading speed". In this example here I used 140 and 20 for unloading, and the final speed is 6 mm/s. During cooling moves the filament moves back and forth by 20mm. So in MM mode the cooling moves are much bigger (double) and take place at a different place higher up in the PTFE tube.

In single mod the cooling takes place in an area from 25 to 35 mm, so the filament is pushed back a bit into the heat break. And the heat break inner diameter seems to be smaller than the inner PTFE diameter. In MM mode the cooling area is from 29.5 mm to 49.5 mm which is in my opinion completely inside the PTFE tube. And so the filament tip forms with that diameter which of course is to big for the heat break tube.

I will do some more tests to see if I can modify the MM procedure in a way that it is more like the single mode ejection sequence.

It would be nice to know why Prusa is using 2 different procedures for filament ejection, and why at different areas inside the hotend.

RE: MMU2S filament tips on unload

@michael-t66

I'm not sure I understand what you mean about the extuder being too warm, and what I can do about that.

I am printing PLA at 185C (which is well below the specified range for Hatchbox), and setting it lower causes the print to fail.

I have the standard Prusa MK3S fan blowing accross the fins of the heatsink above the heater block.

I have the standard Prusa MK3S part cooling fan/blower installed, and it turns on after the first layer is complete.

Would an additional 140mm fan, blowing in from the side really make a difference?

RE: MMU2S filament tips on unload

Well after a view days of testing (changing unload and cooling speed and cooling tube position) and searching the internet I solved my problem with filament tips being to thick to be reinserted into heat break tube.

And the root cause was of course very simple and obvious but I was to blind to see. The root cause in my case was the PTFE tube in the hotend itself. I asked myself how on earth is it possible that the filament tip is to thick for the heat break tube (which is 2 mm in diameter) if the PTFE tube has an inner diameter of only 1.85 mm according to the spec. And so I inspected the tube a bit closer and found the inner diameter being a bit bigger than 2 mm (instead of 1.85 mm), the outer diameter being 4.2 mm instead of 4 mm and length 45.5 mm instead of 44.2 mm.

I replaced the tube with an old one with 50 mm length but correct inner diameter (left over from the last upgrade) which I cut to correct length, and all problems with the filament tips are gone.

Could it be possible that the PTFE tubes are growing by the time? I'm not sure but I don't believe that I got a wrong tube with the upgrade parts for the MMU2S.

Anyway - I'm happy for the moment that this problem is solved (fingers crossed). If you have the same problem that the filament tips are too thick to be reinserted into the heat break tube (but pass through the PTFE tube in the hotend) check the PTFE tube itself for correct inner diameter.

RE: MMU2S filament tips on unload

I haven't got a problem printing Multicolor prints with PLA or PETG with standard settings but a few days ago during a longer print with 2 colors of Fillamentum PLA it failed to load on every color change so I have to stop it.

I tried at least 10 different PLA filaments, tested many different settings (unload speed, cooling moves, ramming, temperature), printed new ir-idlers, done the IR-calibration several times but every printing test the loading procedue failed (except 1... a relative fresh spool of Fillamentum Wizard's Voodoo). After that frustrating tests I tried PETG filaments and didn't have a single loading fail. (I think it loads because PETG is not as stiff as PLA)

Today I read the post of @oliver-r4 and I think it can really be the PTFE tube inside the extruder - haven't tested it yet.

Is it possible that the PTFE tubing gets bigger inside by printing abrasive material? (I printed lots of abrasive filaments like PC, PC-PBT, ABS-Kevlar, Steelfill, Glow in the Dark before)

If that's not the problem, I really don't know what to do.

Thanks to everyone in this forum for the awesome help

RE: MMU2S filament tips on unload

(I think it loads because PETG is not as stiff as PLA)

I have run into issues with Amazon and Inland PLA getting stiff and brittle as it ages and/or absorbs moisture and that starts impacting tool changes as it isn't moving as freely and the MMU will chew notches into it. Skipping the MMU or doing a single color print (once I get it to load the first time) works fine with the same filament and shows no signs of issue in the resulting print.

I haven't tried drying such filament to see if that helps as it's been at the end of rolls anyway so I just move it to my scrap/test pile.

RE: MMU2S filament tips on unload

... it failed to load on every color change so I have to stop it.

Have you made some pics how the tips looked like?

Failed to load is usually caused by thick filament tip, too tight/loose tension screws or the IR sensor lost his calibration (physically). If you have decent filament tips, then PTFE tube is not your problem.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: MMU2S filament tips on unload

@nikolai-r

No, I doesn't made pics of the filament tips but I noticed that the tips of the PLA were a bit thicker than the tips of the PETG.

RE: MMU2S filament tips on unload

In case of thick filament tips, the first step for me is to use default settings. Lower cooling moves to 1, set unloading speed 120, lowering filament temp to most lower range. That should give you thinner filament tips

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: MMU2S filament tips on unload

Is it possible that the PTFE tubing gets bigger inside by printing abrasive material?

I don't think that PTFE tubes inner diameter gets bigger by abrasive material. It's more a growing of the whole tube because my tube had bigger inner and outer diameter as well as a different length.

The question here is why did it fail during your color change? At which point in the filament change sequence exactly did it fail?

RE: MMU2S filament tips on unload

@jeffrey-r10

Sorry, I couldn't catch up on all of the threads. The heat creep I am describing is the one from the stepper not the heat break as on other printers. The glass transition temperature of PLA is somewhere around 65 °C, give or take it. This perfectly matches with the stepper temperature in some occasions. So the bond tech gears are hot enough to make the PLA soft, especially with lots of retractions.

Why a 140 mm fan makes sense placed next to the printer: The stepper itself does have a tiny surface and there is not much around to let the air circulate. At best hot air rises from the hot end. I advised and some agreed to have a 140 mm fan on the outside of the bed blowing some air (hot or cold doesn't matter) over the head just to prove the effect. The solution in the end is either passive or active cooling of the stepper.