New printer and failed prints (MMU2S + i3 MK3s)

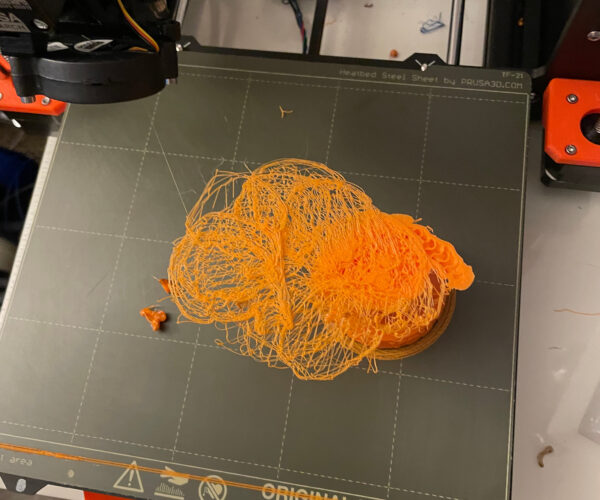

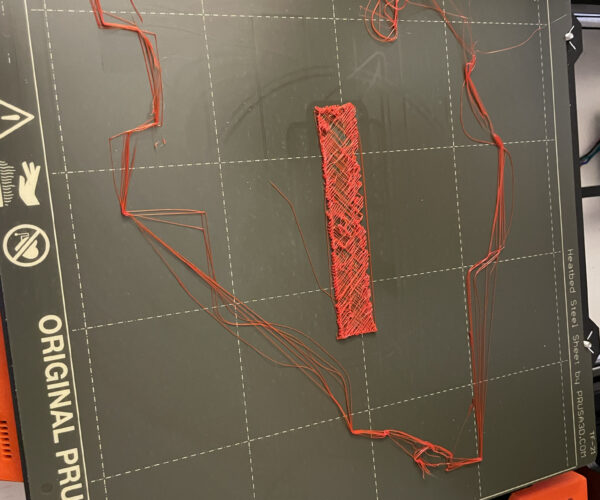

After putting the I3 MK3s + MMU2s kit together I have continued to run into issues with the first layer print and the filament loading. I am able to get the filament to load successfully as per the printer, but the system begins to print with nothing extruding until shortly after it starts what may be layer 2. This continues and looks stringy for a while and then finally breaks free and turns into a real mess.

I have adjusted the temp from 215c to 235c for the nozzle as well as adjusting the bed temp from 60c to 75c with no success.

The bed has been cleaned with dawn several times and 90% alcohol. Attached are a couple of the wonderful prints I was not able to make and any help would be appreciated.

I have taken just about everything back apart in order to figure out what is going on, but I have only succeeded in confusing myself even more.

RE: New printer and failed prints (MMU2S + i3 MK3s)

Take this in stages. For the moment bypass the MMU and let's get the printer running:

Physically disconnect the MMU feed from the extruder so you can load filament manually and follow the first layer calibration procedure then try a couple of plain prints. Once that is working well is it will be time to try reinstating the MMU and working through the load to extruder problem.

Cheerio,

RE: New printer and failed prints (MMU2S + i3 MK3s)

your z offset looks too high to me. I agree with diem. you should not be trying to use the MMU before you've master the basics of the base printer itself. Any problems you have with the base printer will only be multiplied when you add the mmu.

RE: New printer and failed prints (MMU2S + i3 MK3s)

also. cleaning your smooth plate with IPA isn't the way to go. You should be using something like dawn platinum and a dish sponge with the scouring side with hot water. the dawn will break up oils deposited by your fingers. Do this a couple of times and wipe clean with dry lint-free cloth/towel. if your zOffset is right, you should need no glue, etc for PLA to stick and release just fine. For other materials like PETG and TPU you'll want a release agent. for PETG simply spraying on some original formula windows and wiping but leaving a thin layer that you allow ti drive is the ticket. For TPU you'll want the glue stick or else you'll likely pull pieces of your smooth plate off when you remove the print.

RE: New printer and failed prints (MMU2S + i3 MK3s)

btw, you've not mentioned what type of filament you're printing. PLA? PETG? For me the zOffset for PLA and PETG are different for the same build plate. PETG doesn't need to be as close to the build plate.

You can set up profiles for your steel sheets in the printer and then calibrate them and use them as needed.

https://help.prusa3d.com/en/article/steel-sheet-profiles_1955/

you might set up "Spla" for Smooth Sheet + PLA or "Spetg" for Smooth Sheet + PETG, etc. Once defined you just have to remember to go into the main menu and pick the appropriate sheet profile.

RE: New printer and failed prints (MMU2S + i3 MK3s)

@ssill2

All of this was done with PLA and I have removed the power from the MMU so I can focus on just getting a good print. I have cleaned the plate with dawn on several occasions, but I am willing to take any direction I can get as this is a new focus for me.

RE: New printer and failed prints (MMU2S + i3 MK3s)

@james-hill

A clean sheet is fundamental to a good print. the Dawn scrub is always a good start. I even do this on the textured plate every few prints. Unless you're printing something with a lot of build plate contact, like nearly the full plate, you shouldn't need to put anything down on the PEI smooth sheet. if you're having trouble with adhesion do consider doing this calibration. https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/

Take note of the number you come up with. Be aware this number could be different with other materials like PETG and TPU.

RE: New printer and failed prints (MMU2S + i3 MK3s)

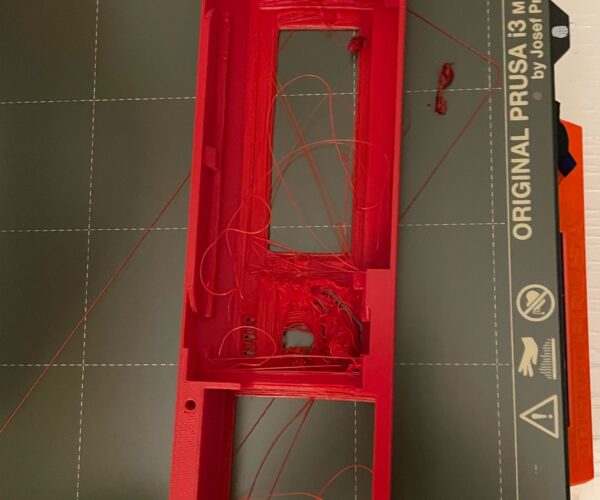

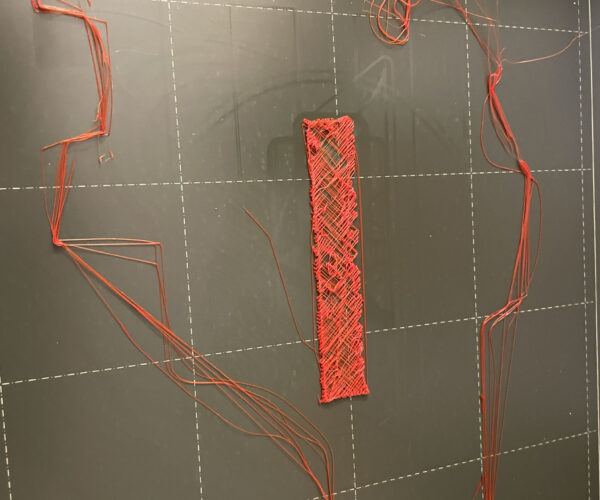

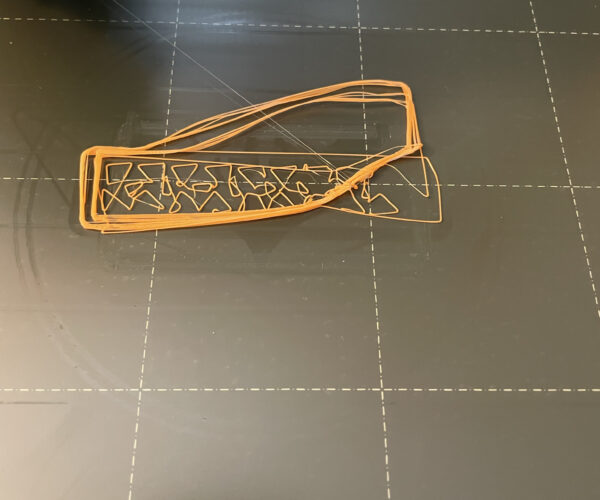

I continue to have hit or miss with printing. I purchased a textured plate and another smooth steel plate and have washed them with dawn and wiped it down with IPA, but I get some stringy prints and I have not even been able to get to the prints I want to print. All of this is with PLA and sometimes I see what looks like a ball of filament on the print or on the bed of the printer. I am trying to get some pictures moved

RE: New printer and failed prints (MMU2S + i3 MK3s)

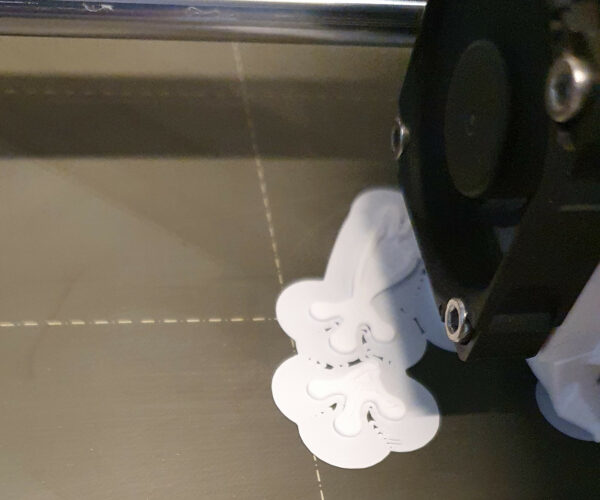

To me that looks like your Z offset is to high. The brim around the frogs feet are loose strings on your print. The brim should be a solid sheet of filament.

The balls / blobs of filament look like filament that stuck to the nozzle/ heatend when the print started to fail en fell of later.

Have a look at the link that @ssill2 posted before about adjusting Z offset.

RE: New printer and failed prints (MMU2S + i3 MK3s)

@james-hill

As Baklin said, brims should be solid. I'd recommend doing the life z adjust 75mm square and taking a picture of that for us to see. When you peel the square off the plate it should come up as a single sheet, and not with the strands separating. if you've still seeing the strands come apart when you peel the square off the plate, you're still not high enough. The textured plate is thinner(a thickness of something like .7mm vs 1mm for the smooth) than the smooth plate and thus you have to use a lower(more negative number) zOffset. You'll want the steel sheet profiles defined so you the printer will save the zOffset appropriate for that sheet.

RE: New printer and failed prints (MMU2S + i3 MK3s)

I just started a quick print to show the brim. This is what the brim should look like.

The brim is used to increase adhesion on parts with a small footprint or when ever you need more adhesion. But to work it should be a connected part.

And that will only happen with the right z offset.

At the moment I have a 0.6 mm nozzle installed. But your brim should look a lot like this.

RE: a little more info

Hi James,

what did the other side of the print look like? can you give us a picture please?

could you save a copy of the project file for this model? ZIP compress it and add the zip file too... please

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

filament type

So the ripples on the bottom suggest z is off. In my experience the correct zOffset for PLA is not the same as for PETG. What kind of filament is that red? I tend to only print parts for the printer on textured plate(because I like that finish) and in PETG. If you got your zDialed in with PLA and then printed a part in PETG(like the lcd cover) then your zOffset is likely too low.

I use steel sheet profiles defined in the printer to easily switch between different steel sheets and filament types. See https://help.prusa3d.com/en/article/steel-sheet-profiles_1955/

I now have three plate types: Textured, Smooth and Satin For each sheet + filament type combo I have a steel sheet profile defined in the printer.

So for PLA I have:

"Spla" for the Satin steel sheet

"SmPla" for the Smooth steel sheet.

For PETG I have:

"Spetg" for Satin steel sheet

"SmPetg" for the smooth steel sheet

"Tpetg" for the textured plate

I also have have profiles for TPU with a similar scheme

Be aware you'll have to go in and rename them and do a first layer calibration before the show up as selectable.

Troubleshooting with reduced complexity

As everybody already pointed out: bed adhesion problems are cleaning and/or z-height problems every time.

Your first layer looks too high. Clean the bed again, run first layer calibration again. Don’t touch the bed surface, if you do: clean the bed again.

To make troubleshooting easier: use Prusa PLA (or any other brand, as long as there are default settings for it in prusaslicer) and use the default settings for printer and filament and start with ‘quality 0.2 mm’. Those settings work! If your prints still fail, z-height is still to high and/or the bed is not clean enough. Don’t change any other settings, don’t install the MMU, adjust the z-height and clean the bed.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

adhesion issue

Hi James,

Are you using 7x7 mesh bed levelling? this is available via the Mk3xx LCD menu

do you use something like 'Life Adjust Z My Way' to adjust your first layer. ?

I wash my Build plate with Dish soap and HOT water, rinse with HOT Water, and dry immediately with plain paper towels.

then for PLA I run the heatbed at 70c for large models...

for PETG, after cleaning the build plate many people wipe the build plate with Windex window cleaner.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

And the beat goes on...

I have not tried printing with PETG as of yet and I am still working with multiple colors of PLA. My Z offset is 1.15 at least that is what it is showing in the live Z adjust screen.

I am printing from my Desktop which is Linux using PrusaSlicer out to a PI running octoprint, and I am sure there are tweaks that could be applied with that setup but I have really been trying to stay as close to base as possible. In Slicer I have set the first layer bed temp to 75 which seems to have stopped the print from moving on higher layers, but I have yet to beat this Z offset.

I purchased a secondary smooth sheet from Prusa as well as the textured sheet for future use. I appreciate all the help and guidance with getting this working correctly as I am looking forward to printing and working with my daughter that is on the spectrum on maker projects at home.

I have not built an enclosure as of yet, but plan on doing that in the near future once I get past this particular issue and I gain a better understanding of the print process.

Thank you again..