First prints with PrimaSelect PVA+ strings

Hello everyone.

I have an MK3S+ with MMU2S. I am using PrimaSelect PVA+ that I bought from Prusa directly. I'm using PrusaSlicer with the filament settings for PrimaSelect PVA+ unchanged.

During filament changes from PrimaSelect PVA+ to generic (Atomic Filament) PLA, the PVA+ strings quite badly, which can cause issues with unloading and/or loading. This then causes the gears in the MMU to grind on the PVA+ and, well, it's all over then. I have to intervene to get the print going again.

The handbook says to adjust the temperature if you experience stringing, but I checked the settings that Prima suggests, and they match the settings that are in PrusaSelect.

I have two questions.

- Is there a standard direction to adjust the temperature to deal with stringing? (Do I increase or decrease the temperature?)

- Does anyone have a custom profile they use more successfully with PrimaSelect PVA+ they can share?

Thanks

Rick

RE: First prints with PrimaSelect PVA+ strings

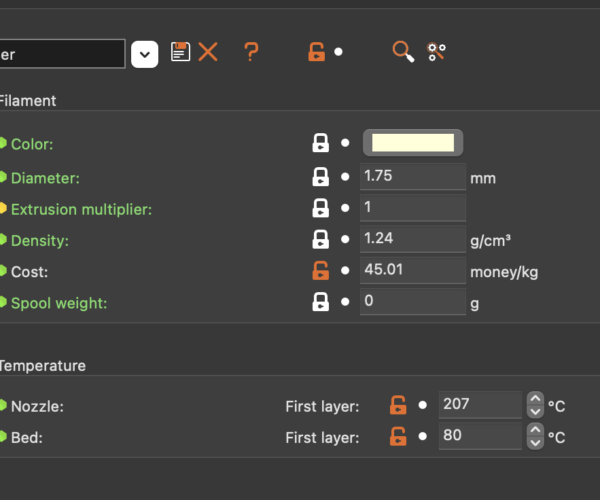

This are the temperature settings I use with Primaselect PVA+ (also bought from Prusa):

Stringing can also be caused by wet filament. PVA+ is very hygroscopic. Do you keep your PVA+ filament in a dry box at all times?

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: First prints with PrimaSelect PVA+ strings

Thanks for sharing your settings. I'll give them a try.

Stringing can also be caused by wet filament. PVA+ is very hygroscopic. Do you keep your PVA+ filament in a dry box at all times?

I should have mentioned this because I've read that about PVA before. I bought the PVA+ for this print. I setup all the other filaments, cleaned the bed, opened the factory sealed vacuum bag on the PVA, loaded it on the printer, and hit print.

Once this print is done, I'm going to be storing it in a gallon zip lock bag with two or three new desiccant bags. I'm going to look into alternatives to that "setup", but for right this second, that will work.

Rick

RE:

Not dry enough. Even new PVA needs drying and once it's been on the printer in the open for an hour or two it will have absorbed more water. Dessicant pouches won't dry it 'though they may prevent further absorption.

Cheerio,

RE:

As Diem said, this is not enough. I keep my PVA+ in a dry box with lots of desiccant (about a 500g per box) all the time (even during printing) and if the desiccant needs to be renewed I also dry the filament for 4h before storing it with new desiccant.

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: First prints with PrimaSelect PVA+ strings

Not dry enough

I don't understand. I literally opened it, fed it through the MMU and started printing. I can't take it off the printer, mid print, to dry it, and I can't keep it in a dry box while printing (I know that this can be done--I don't have the facilities to do it). This is as dry as I can possibly have it for this print*.

Knowing that a few desiccant bags aren't enough for this while I'm not using it will make me look into dry boxes, but for now, there's nothing else I can do.

*This was a 37 hour print that was supposed to end last night at 7:30, but because of the issues with unloading and loading the PVA, it's taking longer. The printer pauses while I'm sleeping, and it loses several hours of time. When I'm awake, if I'm in a meeting, I can't get up and fix the issue, so I might lose an hour or two there, too.

37 hours is far too long to leave PVA (or nylon and some other filaments) exposed to atmosphere. Even if you start dry you will see degredation before half way.

You could print yourself a printing drybox with silica gel dessicant, there are a few designs out there.

Cheerio,

RE: First prints with PrimaSelect PVA+ strings

What Diem said...

I have also seen a guy printing out of a zip lock bag. Just can't find the post right now.

btw here is a dry box design that works and is easy to build: https://www.printables.com/model/63978-ikea-foodbox-drybox-remix

😉

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: First prints with PrimaSelect PVA+ strings

btw here is a dry box design that works and is easy to build: https://www.printables.com/model/63978-ikea-foodbox-drybox-remix

Two questions about this. First, what does the digital humidity meter do besides tell you the humidity in the box? Second, how do you control the humidity beyond keeping it sealed and having desiccants in there? (And an aside I could probably ask Google about, what's the target humidity anyway?)

RE: First prints with PrimaSelect PVA+ strings

what does the digital humidity meter do besides tell you the humidity in the box?

besides telling the humidity it tells the temperature, looks cool and makes you feel better.

how do you control the humidity beyond keeping it sealed and having desiccants in there?

I don‘t. I just renew the desiccant when it is depleted, since it is changing it‘s color when it is, I don‘t even need the humidity indicator for that.

what's the target humidity anyway?

As low as possible. Target is to have the filament absorb as little moisture as possible, so I have to dry it less frequently. In my case I get 17-19% as long as the desiccant is bright orange.

I could probably ask Google about

You probably could, but where would we be, if everybody just googled their questions - much less fun on the forum and no „first layer won‘t stick“-threads anymore…

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: First prints with PrimaSelect PVA+ strings

I noticed something while printing my massive 46 hour print that took 70 hours because of issues with loading and unloading and actually missed three layers or so at the 45 hour print time (not actual time) mark. When the soluble filament was printed, and then purged on the wipe block, while it was being purged, the hot end was heated up from 195 for the PVA to 205 for the PLA. But the PVA was still in the extruder. So when it got pulled out, it was pulled out at too high a temperature.

I looked around, and I couldn't determine if there is a setting I can change to make it so the temperature of the hot end doesn't go up during the wipe step. Is there such a setting?

I also did some testing and found that when I pull the PVA out at 185, 190, 195 and 205, I get the least stringing and the least deformation at 190. At 205 I get really bad stringing, which is the temperature it gets pulled out at during a print.

Any final advice on how to change the settings to the temperature stays steady during wiping would be appreciated.

RE: First prints with PrimaSelect PVA+ strings

Yes, that's a known problem when printing different materials with the MMU, unfortunately Prusa does not seem to care much.

Check out the PrusaSlicer DRIBBLING version here: https://github.com/antimix/PrusaSlicer/releases

or this gcode parser here: https://github.com/workinghard/mmuGcodeParser

happy printing

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: First prints with PrimaSelect PVA+ strings

Have you considered trying dissimilar filaments rather than PVA?

I am not wealthy, so haven't bought any PVA,

the few samples that I have received have not worked out well, so they have never persuaded me to buy PVA.

when I wanted removable Support, I used PLA as a support for PETG. (Using Palette 2S Pro) and it worked well.

the Wipe tower could be peeled apart after the print, and the supports peeled off the print quite nicely

this was a tiny propeller, about 15mm If I recall correctly.

Gold was PLA. Black PETG

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: First prints with PrimaSelect PVA+ strings

I actually made three changes and am reprinting the model. First I changed the temp on the PVA to 190 instead of 195 based on my earlier findings. Second, I changed the layer height from 0.2 to 0.3. Third, I replaced the IR sensor board with a clone I designed that has an LED on it to indicate when the filament is loaded. That required I realign the tower so it's detecting the filament correctly.

I don't know which of the three it is, but since I started this print 14 hours ago, I've only had to intervene once. And then all I had to do was press the right most button the MMU to make it reattempt the load.

Much better results on this print so far!