Re: Testing Print Surfaces

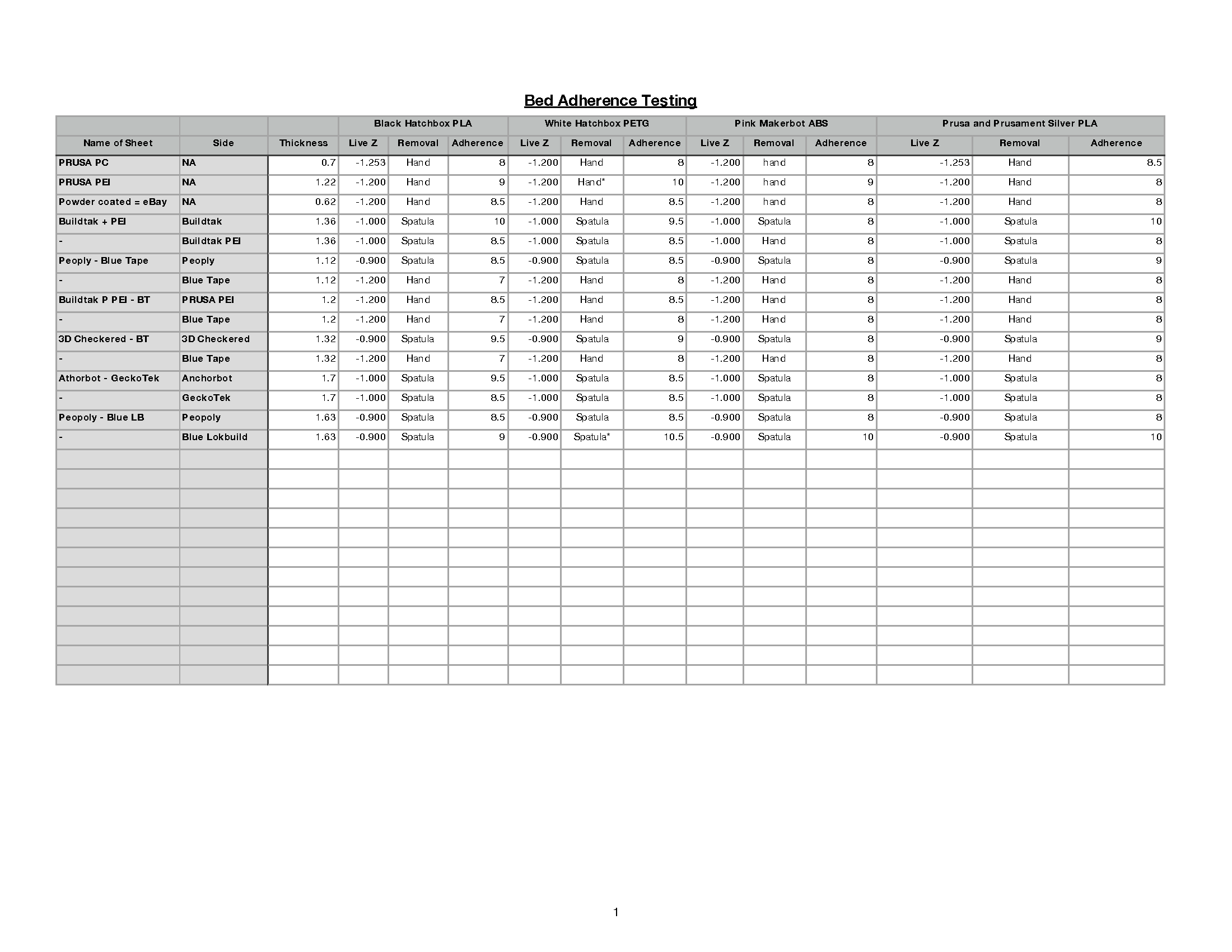

I have completed testing. I printed both the new PRUSA and Prusament Silver. I found that the adherence is similar. I could not tell the difference. I have completed a chart/spreadsheet. I also tested each plate with Pink ABS from Makerbot, Black Hatchbox PLA, and White Hatchbox PETG.

Overall, blue painters take surprises me. I tested three beds with blue tape. I also tested three difference PEI stickers. I like the PEI stickers and Powder coated from PRUSA the most. I think the rest have their place but removing the printed item was often difficult. Especially difficult were buildtak and lokbuild. I think a few of them might be made with similar compounds based on their properties (Buildtak, LokBuild, the 3d Checkerboard (Wisamic), Athorbot). Another surface that prints very well that reportedly works well with nylon (not tested), performed well over all with all filaments tested.

I still have more surfaces to test. Now, I have a bunch of little rectangles to use for something.

I am willing to answer any question and highlight specific surfaces if you have questions.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

Great work!

I have problems with the Prusa PEI sheets printing at high bed temp. Printing Colorfabb nGen at 85°C is resulting in small bubbles on the PEI sheet (but usually still fine). But printing eg PC with 120°C bed temp results in very big bubbles and uneven surface of the PEI sheets.

Re: Testing Print Surfaces

Two things I found,

1. If you do not wait for PRUSA PEI to cool, you can deform the surface.

2. The PRUSA PEI with PETG and ABS sticks better than the powder coated.

This result is with a sampel size of two filaments. I will test more. I do have a roll of colorfab I might test later.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

I have completed a chart/spreadsheet.

Sweet. 🙂

Now, I have a bunch of little rectangles to use for something.

Board game tokens!

That's "MISTER Old Fart" to you!

Re: Testing Print Surfaces

I have problems with the Prusa PEI sheets printing at high bed temp. Printing Colorfabb nGen at 85°C is resulting in small bubbles on the PEI sheet (but usually still fine). But printing eg PC with 120°C bed temp results in very big bubbles and uneven surface of the PEI sheets.

Are these the factory installed PEI sheets or replaced sheets?

That's "MISTER Old Fart" to you!

Re: Testing Print Surfaces

I have problems with the Prusa PEI sheets printing at high bed temp. Printing Colorfabb nGen at 85°C is resulting in small bubbles on the PEI sheet (but usually still fine). But printing eg PC with 120°C bed temp results in very big bubbles and uneven surface of the PEI sheets.

Are these the factory installed PEI sheets or replaced sheets?

Great questions. I tested 4 different PEI sheets and will test more when they arrive.

Amazingly, all worked well and had similar results.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

Ah, good to know. You might add some notes to your summary sheet indicating this approach. I was under the assumption that the 3rd party sheets were stuck to something rigid (e.g. glass) so wouldn't benefit from flexing the sheet for removal. If they were on a flex sheet, that's an important data point. I notice you removed some parts with a spatula. Is this done in instances where flexing the sheet alone doesn't work?

[...] I purchased five buildtak spring steel sheets to test print surfaces. I have applied the surfaces to the sheets with the adhesive.

I was considering doing something similar. I take it, then, that the BuildTak Prusa sheets fit and work well? Did you just re-do the Live-Z calibration when swapping surfaces?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Testing Print Surfaces

I take it, then, that the BuildTak Prusa sheets fit and work well? Did you just re-do the Live-Z calibration when swapping surfaces?

The buildtak spring steel beds are perfect. I did have to reset the live-Z with several fo the surfaces. I recorded them in the sheet to use when I print the surface again.

I am going to so a summary post for each print surface. I am to do some more testing.

I really think quite a few of the third part print surfaces are knockoffs of buildtak. They have similar adhesive properties with the prints.

As I said above, I honestly think the best for the five tested filaments (3 PLAs, PETG, ABS) is blue tape. I have one sheet that has over 20 prints on it with no problems. I have though about testing different types of masking tape.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

Top Rated: Surface: Prusa Powder Coated

Preparation: Cleaned sheet before printing with IPA. I added a spray fo Windex for PETG. No addition for ABS.

Filament: Hatchbox Black PLA, Hatchbox White PETG, Pink ABS from Makerbot, Silver PRUSA (shipped with the printer), and Silver PRUSAMENT.

Live Z: -1.200

Adhesion: 8 out of 10. Prints stick very well. I found no difference between the materials. I am impressed with the ease of print removals with the powder coated bed. It was never hard to remove. I can't wait to buy a second. This bed will remain my bed of choice for PLA, PETG, and ABS. After over a month of printing, it is absolutely the most durable surface I own. Based on the last 45 days, I think it will last at least 12 months. I can't say that for the rest of the surfaces.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

El Cheapo Winner: Blue Painters Tape

Preparation: Cleaned sheet before printing with IPA. I added a spray fo Windex for PETG. No addition for ABS.

Filament: Hatchbox Black PLA, Hatchbox White PETG, Pink ABS from Makerbot, Silver PRUSA (shipped with the printer), and Silver PRUSAMENT.

Live Z: -1.200

Adhesion: 8 out of 10. Prints stick well. I cannot report any issues. I found no difference between the materials. I am impressed with the ease of print removals from the bed. I have no concerns about using these beds as back up. I am only concerned that they may not last long but to be honest after two dozen prints - no issues. It just seems like we should not use such a cheap solution when the issued bed is so great.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

Super Glue Winner: Tie Buildtak and Lokbuild

Preparation: Cleaned sheet before printing with IPA. I added a spray fo Windex for PETG. No addition for ABS.

Filament: Hatchbox Black PLA, Hatchbox White PETG, Pink ABS from Makerbot, Silver PRUSA (shipped with the printer), and Silver PRUSAMENT.

Live Z: -0.900 to -1.000

Adhesion: 10-10.5 out of 10. Prints stick too well. You really need a tool to remove print. I needed a straight blade with a good spatula to remove most. I would only use these with the most difficult to stick surfaces. I can't wait to try them with Nylon and Delrin filament.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

I have completed testing. I printed both the new PRUSA and Prusament Silver. I found that the adherence is similar. I could not tell the difference. I have completed a chart/spreadsheet. I also tested each plate with Pink ABS from Makerbot, Black Hatchbox PLA, and White Hatchbox PETG.

Overall, blue painters take surprises me. I tested three beds with blue tape. I also tested three difference PEI stickers. I like the PEI stickers and Powder coated from PRUSA the most. I think the rest have their place but removing the printed item was often difficult. Especially difficult were buildtak and lokbuild. I think a few of them might be made with similar compounds based on their properties (Buildtak, LokBuild, the 3d Checkerboard (Wisamic), Athorbot). Another surface that prints very well that reportedly works well with nylon (not tested), performed well over all with all filaments tested.

I still have more surfaces to test. Now, I have a bunch of little rectangles to use for something.

I am willing to answer any question and highlight specific surfaces if you have questions.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

I have though[t] about testing different types of masking tape.

There are lots of masking tape comparisons out there, but comparing the "sticky" sides.

I take it you mean testing/comparing the "stickiness" of the non-sticky side.... :ugeek: __ 😀 __ 😆

😆 For some reason, the irony strikes me funny...

(OTOH, it could just be the migraine medication--I'm on day 3 of a real wall-banger... 😥 )

I have completed testing.

....

I still have more surfaces to test.

😕 _____ 😕 _____ 😕

I'M SO BEFUSED ❗ ❗ ❗

I get it, though. Several times when I thought I had completed my spreadsheet of filament purveyors in the USA, a couple/few/several more would pop up later that day (or the next). Like an artist or writer, at some point, ya just gotta say, "OK--I'M DONE--IT'S FINISHED," then don't look back (unless it's the kind of study you want to chase until you drop... 🙄 😆

Now, I have a bunch of little rectangles to use for something.

I reiterate--BOARD GAME TOKENS ❗

I am willing to answer any question....

You mean, like.... What Is the Airspeed Velocity of an Unladen Swallow? 🙄 😆

But serially.... excellent work! If this forum gave out awards for Geekness/Uber Geekness, IMO, you'd be a finalist! (Thing is.... there are so many great Uber Geeks :ugeek: here helping us tyros, I wouldn't want to slight anyone! 😉 )

[EDIT]

DANG, I had typed more, but it just went wherever paragraphs go when text editors go crackers.... 😡

[/EDIT]

That's "MISTER Old Fart" to you!

Re: Testing Print Surfaces

Follow up after another 30 days plus:

Blue Tape: I know no one whats to hear this, but this stuff is the clear winne for ABS and PETG. It does nto stick too much. I am still usign the same sheets I started with on 3 different beds. The prints come off with cooling and have great adhesion (not too much or too little). The best part is that you can get 10 sheets for $24-31 that can be trimmed or rolls for far less at your hardware store.

I still love the PEI TXT PC and PEI sheets from Prusa but I reserve them for PLA.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

Follow up after another 30 days plus:

Charles, are you still doing testing? I'm curious about the PrintedSolid Gecko Tek sheet. They're also selling a bare Mk3 flex sheet for $20 which isn't that much more than the AliExpress sheets if you want faster delivery and support.

I've ordered a couple of the AliExpress sheets for experimentation (before I saw PrintedSolid's) as well as a BuildTak surface with BT & PEI during their combo sale. Looking forward to trying them out. I had a bit of a scare with the one intact PEI sheet on my 1st Prusa sheet, and while I have a spare, I think it's time to have another on hand.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Testing Print Surfaces

Follow up after another 30 days plus:

Charles, are you still doing testing? I'm curious about the PrintedSolid Gecko Tek sheet. They're also selling a bare Mk3 flex sheet for $20 which isn't that much more than the AliExpress sheets if you want faster delivery and support.

I've ordered a couple of the AliExpress sheets for experimentation (before I saw PrintedSolid's) as well as a BuildTak surface with BT & PEI during their combo sale. Looking forward to trying them out. I had a bit of a scare with the one intact PEI sheet on my 1st Prusa sheet, and while I have a spare, I think it's time to have another on hand.

I am testing a Geckotek. I will restart testing in about a week. I am out on vacation in Key Largo.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

If you get a chance try Printbite+. That stuff is dark magic around ABS. Sticks like glue, even with highly warp-happy pieces, then pops then free at 70 C. Need to run hot with it though. 110 for abs.

Re: Testing Print Surfaces

Not sure I understand. You didn't take your printer with you? What's the point?

[...] I am testing a Geckotek. I will restart testing in about a week. I am out on vacation in Key Largo.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Re: Testing Print Surfaces

Not sure I understand. You didn't take your printer with you? What's the point?

[...] I am testing a Geckotek. I will restart testing in about a week. I am out on vacation in Key Largo.

Would not fit in the overhead compartment.

--------------------

Chuck H

3D Printer Review Blog

Re: Testing Print Surfaces

Not sure I understand. You didn't take your printer with you? What's the point?

[...] I am testing a Geckotek. I will restart testing in about a week. I am out on vacation in Key Largo.

Would not fit in the overhead compartment.

tsk tsk. you are supposed to buy your printer a seat of its own....

you are going to give the rest of us 3d printing nut cases a bad reputation if you do not take your printer everywhere.

top tip... when you go to the supermarket give your printer its own cart and rig the battery inverter power system to fit in the space under the basket. then you can attach the printer and its cart to your belt and it will follow you around.... you may have to spend some time when get to the market finding a cart with 4 good wheels and casters as a cart with a flat spotted wheel will induce Z errors in the active print and a bad cater will dive off to one side or the other causing other problems.