Nice to see klipper being used

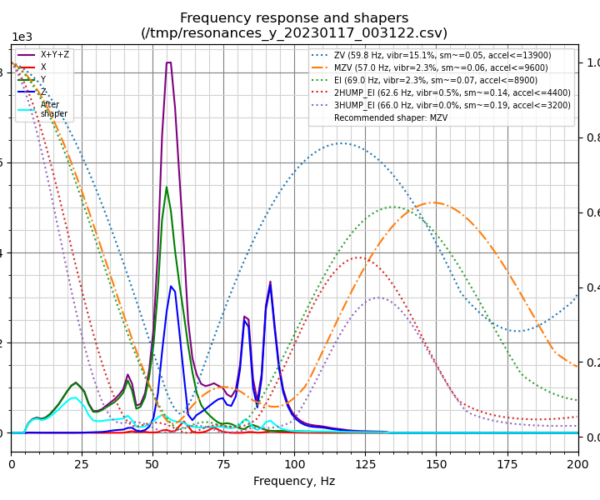

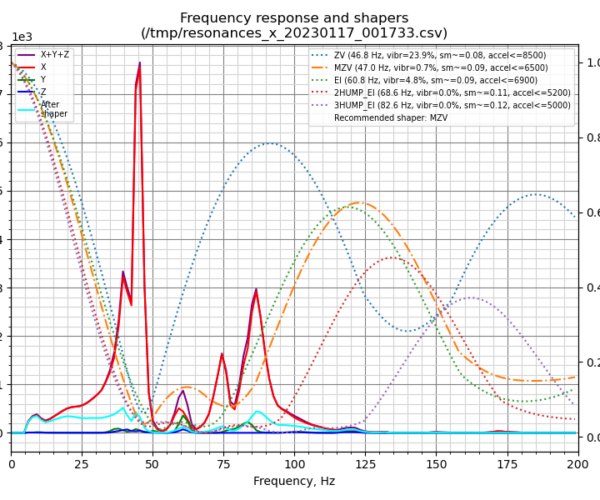

It's nice to see klipper and input shaping being used here. It's an interesting data point but it's probably not that useful for mk3s with stock frames or people with properly tensioned belts. The chart is nice because it tells you where your natural frequencies are. You can see that the axis down at 25 hz might benefit from some stiffening and improve some print quality but largely this data isn't helpful because we don't have input shaping in marlin.... Or slicers.... yet.

This data might be a useful first pass for someone who doesn't have an accelerometer and is willing compromise with using a robust input shaper like 3 hump.

- It's hard to understate how transformative input shaping is for home printers. Hitting 500mm/s is easy now, melting the plastic fast enough is the hard part.

reply

Those data, of course, are anecdotal and I would not recommend using those values for input shaping another printer of the same model.

There soon will be a plug and play solution for the i3 and klipper, which may ease the access of this feature to other users. It is not my highest priority though and therefore might take one or two weeks still.

RE: demonstration

Just to get an idea of what input shaper does. both the same gcode, 250 mm/s with 6000mm/s^2 acceleration, left without input shaper, on the right with input shaper. This is pretty sketchy for the i3 already though.

And just to get how that looks during printing. Exact the same gcode and machine, just different filament. I had to bin that print as that old PETG was too wet.

further

By sketchy I mean, that those speeds and accelerations are a bit on the high side for an i3, in comparison with a fast CoreXY or crossGantry or other printer styles.

I am also not sure if the v6 hotend could actually keep up in flow at this speed, would probably be right on the edge. I replaced the hotend for now, this is a DragonFly hotend (maybe further upgrades coming).

RE: Prusa i3 mks3+ resonance profiles (input shaper)

Have a corexy with a tightly tuned klipper setup + ADXL345. Have been debating moving off of marlin to klipper for a while. Glad to see I'm not alone on this, thanks for the info @marschallmarc

RE: Prusa i3 mks3+ resonance profiles (input shaper)

After watching Michael at Teaching Tech on YT display some compelling examples of input shaping with Klipper it seems like investigating Prusa+Klipper+Input Shaping might be worth the hassle.

RE: Prusa i3 mks3+ resonance profiles (input shaper)

FYI for those not interested in fixing resonance via deep diving into software, it looks like a company called Prorifi3D created an add-on kit in an attempt to improve resonance via hardware. Unclear if the kit actually works.

RE: Prusa i3 mks3+ resonance profiles (input shaper)

The Prorifi3D kit is a stepper motor upgrade though, not really an overall resonance improvement for the machine.

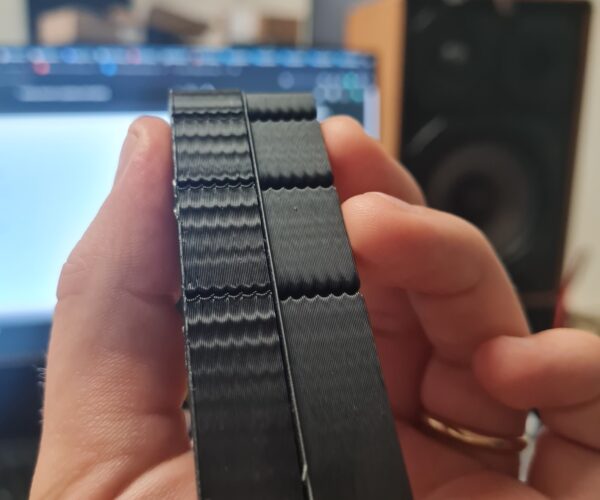

To improve the resonance situation we'd need to do things like stiffen the frame, reduce weight of the print head or moving bed assembly, reduce the spring effect of the belts, reduce friction, etc.

I run a modified Ender 3 on Klipper and it's Y axis peak is around 42 hz. The Prusa has a pretty beefy bed frame (to keep the bed flat I expect) and that's probably part of the issue. If we could get that part reproduced in Titanium the Y axis would be much improved.

RE: Prusa i3 mks3+ resonance profiles (input shaper)

While I planned to allow a simple upgrade path to klipper, I got so say, that this project is kind of on ice for now. Too much other printer stuff going on for me to care much about that i3 ATM.

FYI for those not interested in fixing resonance via deep diving into software, it looks like a company called Prorifi3D created an add-on kit in an attempt to improve resonance via hardware. Unclear if the kit actually works.

This is another type of resonance. What we talk about here is the resonances in the frame, what they talk about is motor resonances and the lack of smooth stepper operation due to that (which they manage to impressively oversimplify and fail to tell that this is known for decades and represented in many data sheets of motors...)

RE: Prusa i3 mks3+ resonance profiles (input shaper)

I just re-tested my Ender on Klipper last night and the Y axis resonance peak is at 48 hz, so much better that the 35 hz or so of the Prusa. My Ender uses a stock bed and single linear rail instead of rollers.

I wonder how much of it is related to the Prusa y axis stepper mount. That thing flops around like a carp.

RE: Prusa i3 mks3+ resonance profiles (input shaper)

I thought I would jump in & post just a bit about Input Shaper.

First, the main purpose of Input Shaping is to reduce ringing in prints caused by sympathetic vibrations. Ringing tends to worsen as print speeds are increased. Input Shaping not only reduces ringing at a printer's normal speed; it allows for the possibility of increasing print speeds significantly while still canceling out most ringing.

Second, Input Shaping is built into Klipper, which is 1 of several reasons to consider using it.

Second, the 2 graphs shown in the original post represent the X and Y axes, 1 graph for each. They indicate when the printer vibrates more because the movement of the axis being tested is at a sympathetic frequency. 2 graphs are needed because the axes are tested separately.

Third, the way Input Shaping is done with Klipper is by the use of an accelerometer. Most often, an ADXL345 is used. This is a small, inexpensive circuit board that responds to motion in X, Y, and Z directions.

To test the X axis, the board is mounted to the print head assembly, usually with a screw or 2. A cable is run from the ADXL345 to the Raspberry Pi that is typically used to run Klipper.

To test the Y axis, the board must be attached to the print bed.

Typically, no testing is done in the Z axis direction, mainly because the Z axis moves much slower than X & Y.

Fourth, while Input Shaping is a definite reason to use Klipper, it's not the only 1. By using fluidd or Mainsail as the front ends to Klipper, it is possible to very easily update many print parameters that would ordinally be buried in the firmware. Klipper uses a file named print.cfg. A whole slew of printer settings are recorded in the file. It is a simple text file that can easily be edited. In fact, fluidd & Mainsail let you edit it right from within their interface.

This concept makes it possible to fine tune printer settings without have to edit source code, compile, and flash new firmware. Simply edit printer.cfg, save & restart Klipper to implement the changes. Restarting Klipper is easy & quick.

I have used Klipper very successfully on my Ender 5 Pro. It really is a game changer. That said, I have not "Klipperized" my MK3S+. To be honest, I'm a bit afraid to because, as I've seen in so many places, the MK3S+ "just works".

BTW, fluidd & Mainsale, like OctoPrint, are web servers. You access them from any browser.

RE: Prusa i3 mks3+ resonance profiles (input shaper)

@MarschallMarc

Thanks for posting your charts! I've been wondering about the resonance profile of the mk3 for a while. "not exactly impressive" is an understatement - it's basically unusable. Even with the most aggressive shaper there are still residual vibrations and the amount of smoothing is like nothing I've ever seens (and I've looked at a lot of resonance charts)

Anyways, thanks again for posting the charts! Just install klipper last night so I hope to do IS today. I'll report back in this thread.

I really want to know how consistent the frequency response is from machine to machine.

RE: Prusa i3 mks3+ resonance profiles (input shaper)

Thanks for posting.

You have given me much reading and motivation in order to learn more about Klipper.

REPAIR, RENEW, REUSE, RECYCLE, REBUILD, REDUCE, RECOVER, REPURPOSE, RESTORE

RE: Prusa i3 mks3+ resonance profiles (input shaper)

I'm abandoning Prusa if they don't drop an experimental update with input shaper. It's been too long with no real jump on advancement. Please Please Please rush this before you lose your base.

RE:

My results were much better. I'm not sure if the belt tension plays a significant role.

Can you tell us more about your setup? I'm getting pretty strange results, but I'm also brand new to looking at these charts. None of the YouTubers charts look like this, so I'm trying to understand how much of a problem I have and how to diagnose. My KUSBA is mounted where the KUSBA Z = Printer X.

RE: Prusa i3 mks3+ resonance profiles (input shaper)

Which Accelerometer do you guys and ladies recommend for the i3MK3S+?

RE: Prusa i3 mks3+ resonance profiles (input shaper)

I would like to use Klipper instead of the Marlin. Is it difficult to convert?

It depends. If you use the prusaowners klipper fork and follow their docu you can make the switch in 2 hours.

If you are familiar with everything you can use something like fluiddpi and set it up in 3h.

If you have no idea about it and want to go from scratch, it can be a very long journey.

To install Klipper you have to change bootloader and FW. Setting and configuring the parameters takes a lot of time and patience. You can use templates (especially the Prusa FW settings), but in the end you have to find the individual optimal settings for each printer. Some users in German-speaking countries including myself are already working with it. But I am constantly optimizing. Input shaping is a special chapter. So far I have documented most "How to install Klipper" processes, but only in German.

I have not yet specified a graphical user interface. But for now I work with Octoprint and a special plugin.

Klipper is something for hobbyists and tinkerers - not a finished product, as well as the Prusa FW.

wbr,

Karl

I did not have to change the bootloader on my Einsy Rambo (I bought my i3 mk3s+ from Prusa, so no clone). I was able to flash it via USB without any preparation. It seems like there are different revisions out there, as others reported to need to flash a bootloader first.

Prusa put a lot of work into finding good standard settings for Marlin and you can use those (and add something like 0.045 PA) in klipper as well. This way your printer will already work as good as it does with Marlin settings wise (and some things better others different). It is an inherent property of 3d printers that optimizing settings for individual machines gets better results.Klipper is something for hobbyists and tinkerers - not a finished product, as well as the Prusa FW.

I very much disagree on that one. It is in fact much better in a farm environment than Marlin is and allows very easy central management.

The difference simply is that nobody prepared klipper for the i3 with the same dedication as Prusa prepared Marlin. The code base of klipper is also much more professional than the Marlin base.My goal was not to convince anybody here of klipper, I really just wanted the graphs to be available.

Which prusaowners klipper fork are you referring to? Any link?