E3D Revo 6 hotend, Arrived and so far I'm not impressed

Ok, Some background, I've had my MK3S for a few months now and had some greaty prints off it. I don't do anything really complex just for product prototypes and general useful items for use around the house / car / bike etc. I then added a MMU unit and again, no problems for me, or nothing that a little bit of tweaking with the load and unload buffer didn't sort out. However, I ended up moving my printer a few times from workshop to house and back again and then there were a few issues with printing but again, re calibrate and adjust and back to fine. So i think i know roughly what i'm doing and if not i'll google or ask for help.

I saw the revo hotend and thgough whilst there wasn't much of a diffrence in quality of prints the idea of changing the nozzels appealed, changing on the standard v6 was alway a little scary with having to grip the heater block to stop it twisting. So mine arrived today and after reading a couple of reports of issues with use with a mmu i thought i'd swap back to single filament. This a i did and ran a couple of test prints, both of which came out fine.

So i swapped to the Revo 6, the install was fine, although it would have been nice if they supplied the PTFE tube cut to size and with the tappers already done to make the job easier and eliminate a potential error on user install. After the install i ran the PID calibration and started the bed level from zero again, just in case. that seems to be correct. However here comes my gripe, the nozzels you can't change when hot as was claimed as even with the rubber on it's just too hot, but that's minor. But for the fact that every time i try and print I don't get a even first layer, it's either too close or too far away, i've had the nozzel catch the print as it moves and whilst the original V6 was a doddle to set up and get great prints, this seems to have altered things so that i have to constantly tweak, even to the point where swapping from 0.4 to 0.6 gives me vastly diffrent results.

Now i was used to the MK3S just working and not have to constantly check and monitor like i did with my ender 3 and artillary sidewinder, that's why i got rid of them. So whilst i'm sure it's something that i've done or altered which i need to find, so far i'm not impressed as it's not as straight forward a swap as all the reviews and website makes out.

So if anyone has any ideas that i could check and adjust i'd be grateful as i still like the idea of the nozzel change but only if it works from one nozzel to another without having to re-calibrate every time.

PS i've done all the self test's and checked for tightness but i'm quite happy to start again if needed.

PPS: I'm thinking now if it was something to do with the PTFE tube, have i put it in correctly etc??? would that cause issues?

RE: E3D Revo 6 hotend, Arrived and so far I'm not impressed

as straight forward a swap as all the reviews and website makes out

Well, I certainly didn't read all reviews but in the ones I read reviewers highlighted several issues, and all state (sometimes just as an aside) that live z calibration is certainly not a thing of the past.

My Revo is still unpacked, as my Dragon hotends haven't given me any reason to replace them. But I'm certainly not surprised to hear that swapping the nozzle doesn't alleviate the need for recalibration. Looking at the design, I don't see why there wouldn't be small differences in hotend length upon nozzle swaps, the same way changing from one nozzle to another on a V6 may require Live Z readjustment, just due to the way the nozzle caught when screwed in. Given how just a few microns can make a big difference in a first layer, I don't think any of these hotend technologies have such low tolerances that nozzle changes will just be a simple swap, unless you do something like the XL is supposed to do, use the nozzle itself to automagically self-calibrate.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: E3D Revo 6 hotend, Arrived and so far I'm not impressed

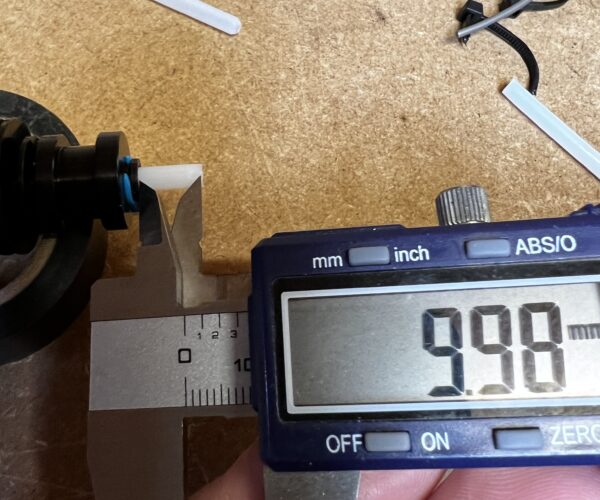

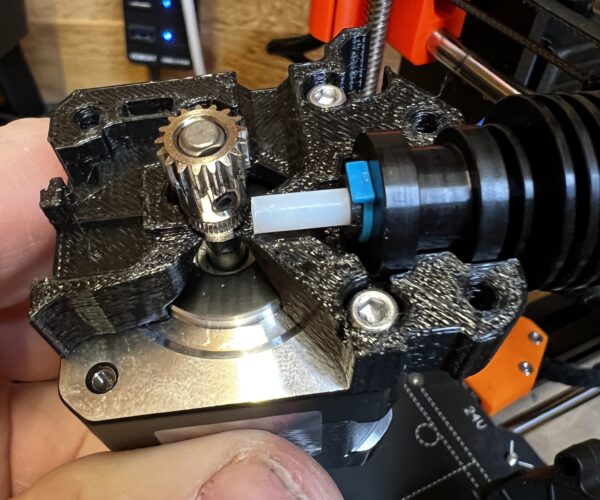

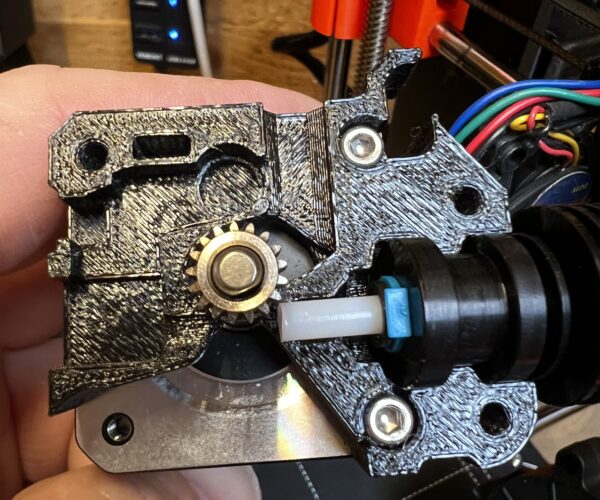

A quick update, As I suspected it was user ( idiot ) error on my part, basically the PTFE tube was too long,I'd read the instructions wrong and measured from the wrong part to get the 10mm. I've altered that now and it all seems to be workig well so far.

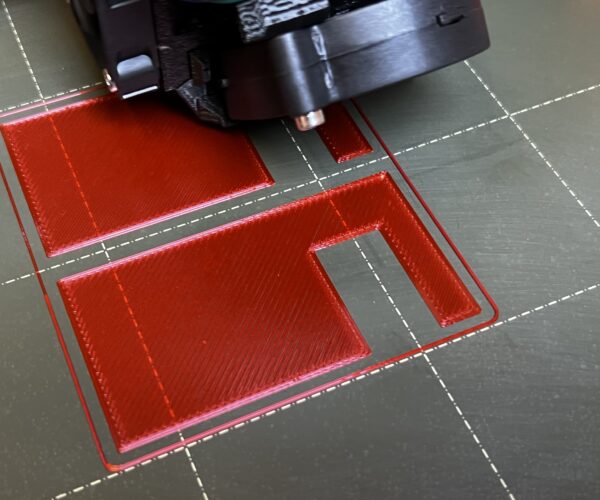

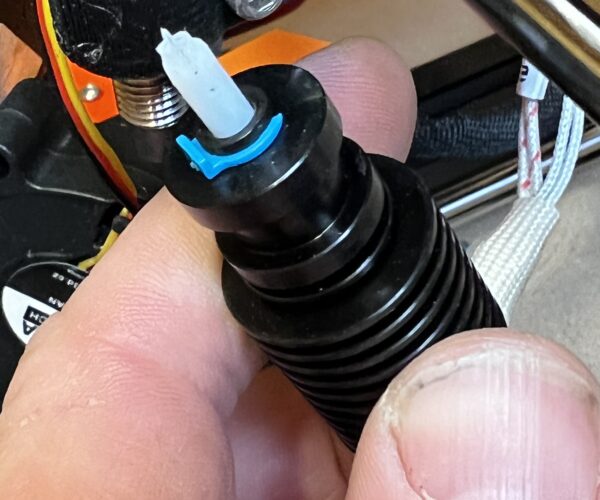

So if you get one make sure you don't measure from the top of the retaining clip like i did but from the body or you will be 3mm or so too big. Again, supply the PTFE tube and it eliminates this error. Photos attached showing the result of the too long PTFE and the correct PTFE printing

layer

layer

RE: E3D Revo 6 hotend, Arrived and so far I'm not impressed

Thanks for the pictures! I bookmarked this thread so when i get the revo, I can come back for reference!

-Nigel

RE: E3D Revo 6 hotend, Arrived and so far I'm not impressed

Best also bookmark the upgrade guide from the manufacturer while your at it: Revo-Six-Prusa-MK3S-upgrade-guide

RE: E3D Revo 6 hotend, Arrived and so far I'm not impressed

Awesome even more info and details! Wonderful. I plan on doing this when I upgrade to the + for my mk3s that has been sitting in the box for a little while now. I just didn't want to take everything apart then do it again. Thanks you!

-Nigel

Best also bookmark the upgrade guide from the manufacturer while your at it: Revo-Six-Prusa-MK3S-upgrade-guide

RE: E3D Revo 6 hotend, Arrived and so far I'm not impressed

Yes, I did the exact same thing a few weeks ago. I had assembled the enclosure, tested it with some ASA prints, saw that the fan shroud for the nozzle was in a state of metamorphosis and then I did the upgrade, having printed the necessary parts for the + some time ago after getting the upgrade kit. Went smoothly. There is a distinction for the length of the PTFE tube if you disassemble the parts from the MK3S and assemble the parts for the MK3S+ so the new parts need a different length than the old ones, as mentioned in the posts above. There is PTFE tube in the upgrade kit from Prusa and in the Revo Six kit as well. Hope it goes well for you too. Changing nozzles on the old V6 hotend is really a pain in the you know what. 🙂