No Luck Printing Anything

Printing has been going from bad to worse for me and I don't really know where to go from here. Any help would be greatly appreciated. I probably need to find a local user group where I can get some help.

Here is a laundry list of problems I am experiencing using the original i3 with a brand new Rambo Mini v1.3. I just replaced

• When printing ABS the nozzle is unable to reach the recommended 285C. Stays stuck at about 270C-275C

• I have tried to used PLA at lower temperatures but it won’t stick to the plate.

o I have tried heated bed with ABS Juice and blue painters tape

o This video shows it not sticking to the tape http://1drv.ms/1K7zoC9

• When using ABS filament I can no longer get the first layer to stick to the plate.

o When using ABS filament, I have cleaned and prepped it with glue-stick and ABS juice as recommended in the Material Settings.

o I have leveled and set spacing between plate and nozzle repeatedly

o I believe it is not sticking because the nozzle temperature never reaches 285C as mentioned above. Should that be replaced?

• When using PLA filament using recommended Slic3r settings it prints way too fast

• I started using Simplyfy3D but it seems the flow rate is too slow and it never sticks to the plate. I would like to have Prusa recommended settings for Simply3D software. I saw someone posted for the 1.75mm version of the i3 but none for the 3mm version

Re: No Luck Printing Anything

Hi Tim

First thing, having replaced your RAMBo, do you have the correct (3mm) firmware installed? Your comment regarding Slic3r may indicate an incorrect firmware, but your being able to reach those temperatures tends to indicate you do have the correct firmware.

The lack of stick, I would assume is to do with the calibration, but again you seem to have addressed that one. I don't think it's temperatures preventing sticking - with the 1.75mm version I can print ABS @ 230 with very good stick. As long as the bed is hot enough (same with PLA). I use at least 45 degrees when printing PLA onto blue tape - you must clean the tape with isopropyl alcohol after placing on the glass.

Have you tried a thick first layer (0.5mm) - possibly printing like this with a raft?

The video appears to show the extruder not pushing out the filament properly. Can you feel the filament being fed?

How long has your filament been out of the box? If it's been a couple of months, it could have become saturated with moisture.

The nozzle is obviously pre-used and presumably it reached the temps before, so can you check the connections at the RAMBO? Tight screws, connectors firmly pushed into the sockets.

Correct voltage set on the PSU?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: No Luck Printing Anything

I will check the firmware as that makes a lot of sense even though I was told that the Prusa staff flashed it already befor shipping. They could have put the wrong firmware on it.

I am able to see filament push through the nozzle using the extrude commands on my software. It flows pretty well even if the temp not at 285. It is only when it starts printing does it seem to not push enough through.

I have new filament and live in Southern California where it is pretty dry most throught the year. Good to know about the moisture issue but I don't think this is the problem.

I have had somewhat OK success printing prior to the terminal block burning up on my last Rambo. It is only sinse this new one was installed have I had problems.

I really would like a set of Simplyfy3d Settings preconfigured for my printer as I am not experienced with all the nuances of them.

Re: No Luck Printing Anything

Tim

The 1.75mm firmware had a temperature limit of just below 260 degrees, above that and you would get a MAXTEMP error, so I don't think it is firmware. But the way it does not appear to be extruding properly is very strange.

If the only issue with your old RAMBo was a burnt out connector, could you not simply solder the heater wires onto the bottom of the board?

Unfortunately, you may be on your own with Simplify 3D settings, unless you can get Josef or someone else on the forum to generate something for you. Thought... Why not post a request on the Czech language forums (in English). Most of the guys there speak good english and there is probably a better chance of getting something from them.

With regards to your main problem, I think your best bet to to contact support via the live chat on the shop pages, giving them a link to this thread.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: No Luck Printing Anything

Hi Peter.

Take a look at this video I made. Perhaps you can tell what is wrong. Thanks for your help

Re: No Luck Printing Anything

I have verified and re-flashed the firmware to be sure it is the 3mm version.

Re: No Luck Printing Anything

Hi Tim

I think this may be one for Josef to look at...

There's not a lot more I can think of. You fed 100mm during the extrude test. Is that 100mm of raw filament or 100mm of extruded filament?

Put the nozzle up high and try again; this time measure the amount extruded.

I don't think there is any clogging in the nozzle or extruder. When printing the manual feed wheel seemed to turn as it should - but I have not seen the 3mm version of the printer.

Have you tried compiling the firmware yourself? Try flashing firmware version 2.1.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: No Luck Printing Anything

No I have not compiled the firmware myself. I want to keep things straight forward and use the published versions on the Driver pack page. Apparently that is not even safe for me 😐

Can you have Joseph look at this ? Or how should I get his attention?

Re: No Luck Printing Anything

Hi Tim

Did you try the extrusion test I mentioned?

I am sure that Josef will be here soon to have a look, but unfortunately I have no idea whether he is available or out of the office.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: No Luck Printing Anything

Hi Tim,

Couple things I found with my 3mm version before I upgraded.

- Temperature for ABS did not need to be 285 for it to work, I typically used it lower than that, more tailored to the manufacturers settings.

- Tension applied to the filament by the idler wheel was important. I found if I had the screws too far in they would actually inhibit the extrusion

- I had a problem with the large drive wheel very early on in the piece, everything would look fine but the correct amount of filament was not being extruded. This caused heaps of problems. What I found was that the locking nut which is embedded in the big drive wheel was actually slipping, thus the big drive wheel was turning but due to the slipping, the extruder drive wheel was not turning correctly.

- I find first layer is critical for ABS, I try to make sure the actual height for the first layer is actually slightly lower than the system thinks, thus really pushing the ABS into the juice.

- I always try to make sure my ABS juice is thick and the PVA glue is dry. I also understand that some PVA glues work better than others.

Angus

Re: No Luck Printing Anything

interesting. thanks agnus

Re: No Luck Printing Anything

Printing has been going from bad to worse for me and I don't really know where to go from here. Any help would be greatly appreciated. I probably need to find a local user group where I can get some help.

Here is a laundry list of problems I am experiencing using the original i3 with a brand new Rambo Mini v1.3. I just replaced

• When printing ABS the nozzle is unable to reach the recommended 285C. Stays stuck at about 270C-275C

• I have tried to used PLA at lower temperatures but it won’t stick to the plate.

o I have tried heated bed with ABS Juice and blue painters tape

o This video shows it not sticking to the tape http://1drv.ms/1K7zoC9

• When using ABS filament I can no longer get the first layer to stick to the plate.

o When using ABS filament, I have cleaned and prepped it with glue-stick and ABS juice as recommended in the Material Settings.

o I have leveled and set spacing between plate and nozzle repeatedly

o I believe it is not sticking because the nozzle temperature never reaches 285C as mentioned above. Should that be replaced?

• When using PLA filament using recommended Slic3r settings it prints way too fast

• I started using Simplyfy3D but it seems the flow rate is too slow and it never sticks to the plate. I would like to have Prusa recommended settings for Simply3D software. I saw someone posted for the 1.75mm version of the i3 but none for the 3mm version

All of this worked before the change of the rambo?

I attached the S3D settings we use to print production parts.

Re: No Luck Printing Anything

Yes this is correct. I have not been able to print anything well since replacing Rambo. I am spending huge amounts of unproductive time 🙁

Re: No Luck Printing Anything

What firmware do you have in the RAMBo?

EDIT: I am bit slower today, this was already answered 😕

Re: No Luck Printing Anything

Tim.o I rechecked the videos, you cannot simply change filament diameter from 1.75mm settings to 3mm settings, there is e-steps per mm setting in the start g-code (M92 E161.3 EDIT: which is the incorrect value for the 3mm version). Please power cycle the printer and try printing something from our provided test objects for 3mm or generate something with 3mm Slic3r from our latest drivers. So we can rule out some options and move forward to finding a solution.

When you print on tape, don't forget to clean it with alcohol before printing.

EDIT: And please check the hobbed pulley and clean it, the high speed extrude due to wrong esteps definitely stripped the filament.

Re: No Luck Printing Anything

ok thanks. I plan on putting some time into this this weekend.

Re: No Luck Printing Anything

Ok I downloaded the production S3D 3mm 250um fff file and am trying to run a test print.

I am using the Blue 3mm filament that came with my printer because I have had success with that in the past.

Your file specifies nozzle temp of 295 but my machine won't go higher than 265. What is the problem with it going higher?

Thanks

Re: No Luck Printing Anything

Tim

The HEATER_MAXTEMP in firmware for the 3mm version is 315 degrees, so it should be more than capable of getting up to temperature. Only thing I can think of is to make sure the part fan is turned off. Either that or you have a cable./connection problem.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: No Luck Printing Anything

The fan automatically goes on when temp >50 degrees. I thought that was by design.

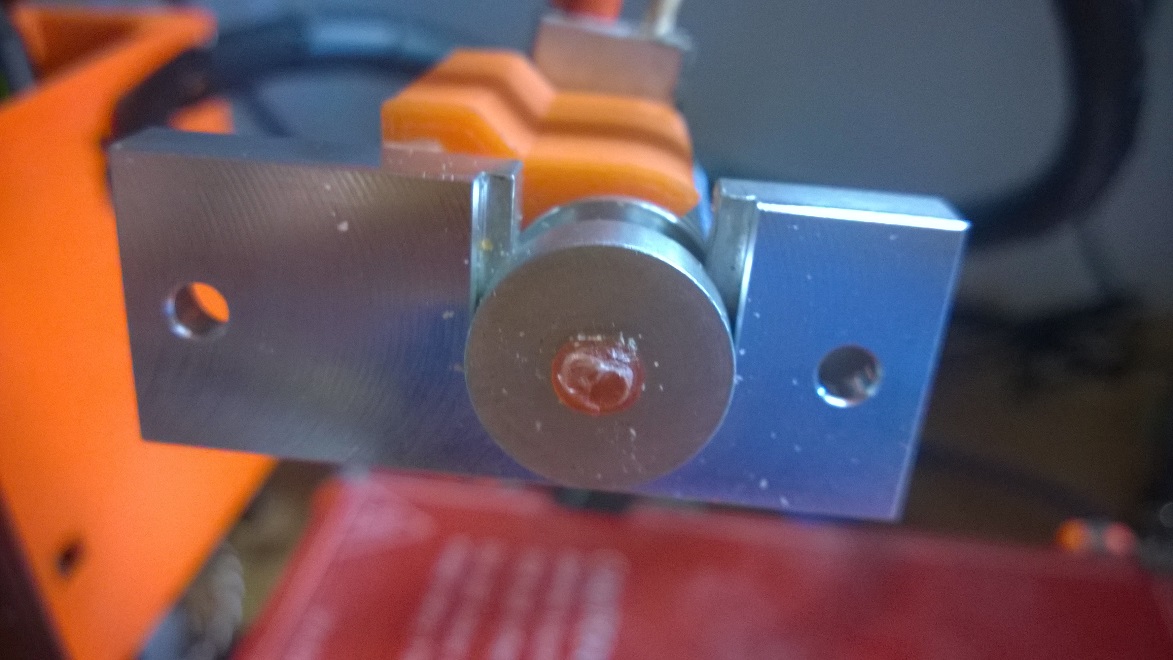

There was a time when my fan did not go on because of loose connection and that resulted in jammed filament at the very top. I posted on this forum about that as well. Here is the jam:

This video demonstrates what I am experiencing. Looking at this video I have to think perhaps S3D is altering the firmware. My understanding is that it can do this as a feature of the product. It would be nice if S3D had a dedicated machine profile for this Prusa i3.

Video Link: http://1drv.ms/1W24e5h

Re: No Luck Printing Anything

Tim

When printing with ABS you should not use the fan.

When printing with PLA you should be printing at a maximum temperature of 230 degrees (usually much less).

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…