Gaps in perimeter and between perimeter and infill at 45 degree angle

Hi,

Have an issue with my prints. I am printing a cylindrical piece and I noticed there are gaps forming in between the perimeter walls. As well this gap exists in between the perimeter and the infill. What is odd is that it's always at at 45 degree angle to the x-axis. The rest of the wall/infill is fine.

I was reading something where if you get gaps like this it's because of a loose belt but they describe the gaps as being in-line with the axis that is loose. However I tightened my belt (x-axis) and nothing changed.

I did notice however that the x-axis belt is tighter on the top than on the bottom. Is that normal? The y-axis is already pretty tight so I did not adjust that one. I also noticed that my x-axis belt is starting to show wear - it's only a month old - is that normal as well?

I realize a picture would help but I am not home right now. I will post a pic if anyone thinks it will help or if someone knows what the issue might be please let me know.

Thanks,

Jason.

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

Jason

Pictures will help.

the x-axis belt is tighter on the top than on the bottom

No, not possible... It is one single belt with a free pulley at one end. The tension is the same throughout the length of the belt.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

Jason

Pictures will help.

the x-axis belt is tighter on the top than on the bottom

No, not possible... It is one single belt with a free pulley at one end. The tension is the same throughout the length of the belt.

Peter

Thanks Peter, I will post a picture tonight.

Yeah I know it weird about the tension on the belt but I swear that's what it is like - there is a noticable difference between the top and the bottom. The y axis doe not have this issue it's uniform throughout.

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

The tension will seem tighter on the shorter top runs simply because they are more constrained.

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

That's physically impossible unless the idler is somehow badly stuck.

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

guess I should stop posting on this forum, that's twice in one day I have been flamed...

tension in belts in normally tested by either deflection or twang tone,

if the bottom belt run is 12 inches long and the top run is for argument's sake two 5 inch segments ( bed in centre of run and 2 inch mounting for belts) then the 12 inch run will deflect more for a given input than the 5 inch segment. and the 12 inch run will have a lower pitch when twanged than the shorter lengths,

either instance may suggest that the shorter belts are tighter,

I would however prefer it if people withheld negativity and accepted that different people have different points of view... and that we are actually trying to be helpful

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

guess I should stop posting on this forum, that's twice in one day I have been flamed...

And you were right both times... Don't let it bother you.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

Fortunately physics does not consider different points of view. 😉 No offense.

The key information is that the belt cannot be tighter on top part compared to bottom part regardless of what it seems to be. I think we all agree on this.

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

David

Re-read Joan's posts. On both occasions, what was written is totally correct.

The tension will seem tighter on the shorter top runs

and

may suggest that the shorter belts are tighter

Now can we get back to the subject of the query and await the required photographs?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

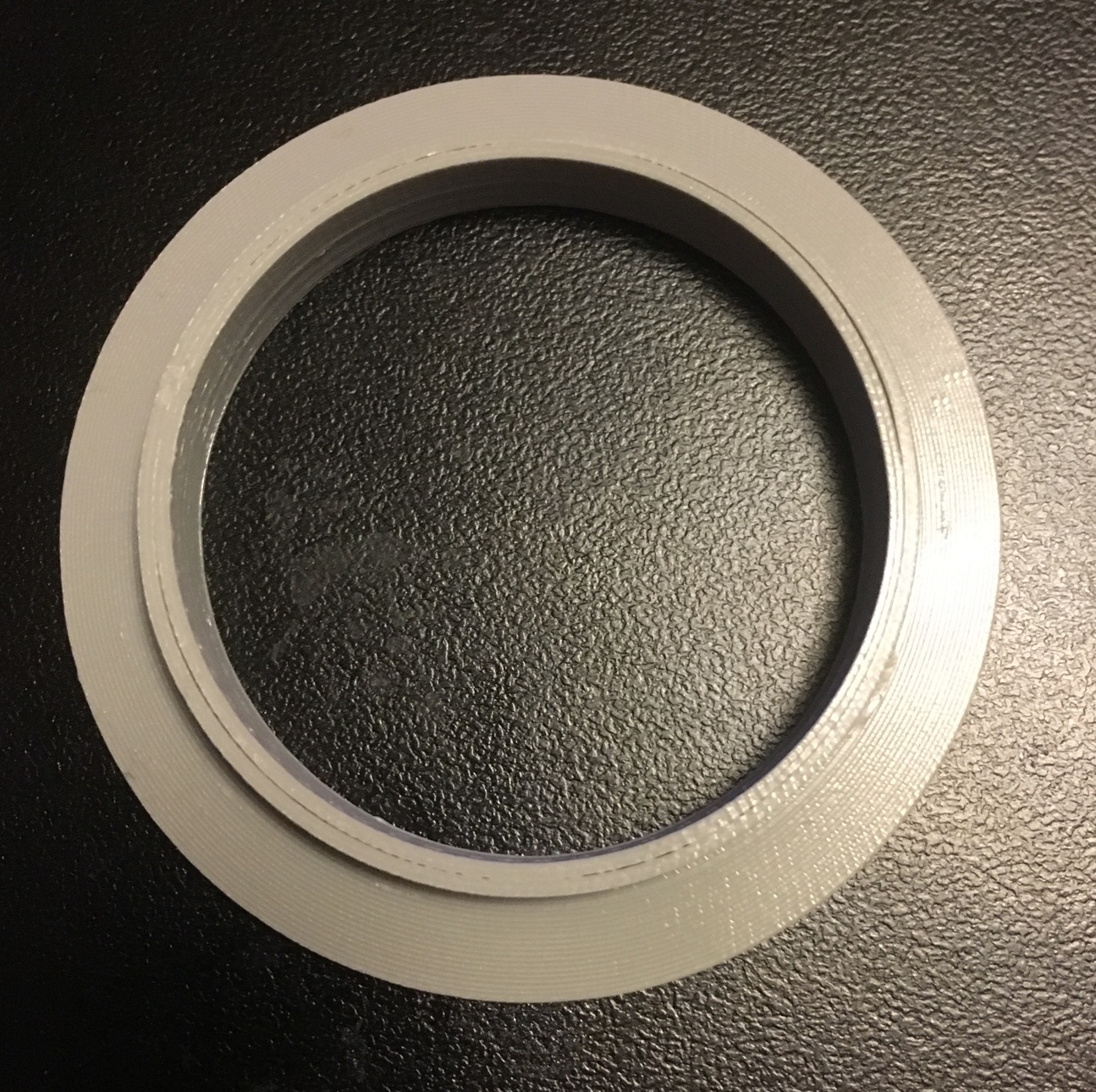

Thanks for your help guys. Lets not fight over my perception that the bottom is looser. I checked the idler and I think it was too tight, it didn't seem to move. I loosened it a bit and reprinted my piece. It printed better but still not perfect but the gap is about half what it was and the bottom was more even. I tightened the belt a bit more and new the tension between the top and bottom **feels** (not saying IS) much closer to one another. I am also rerunning my XYZ calibration. I will post a result once it is done.

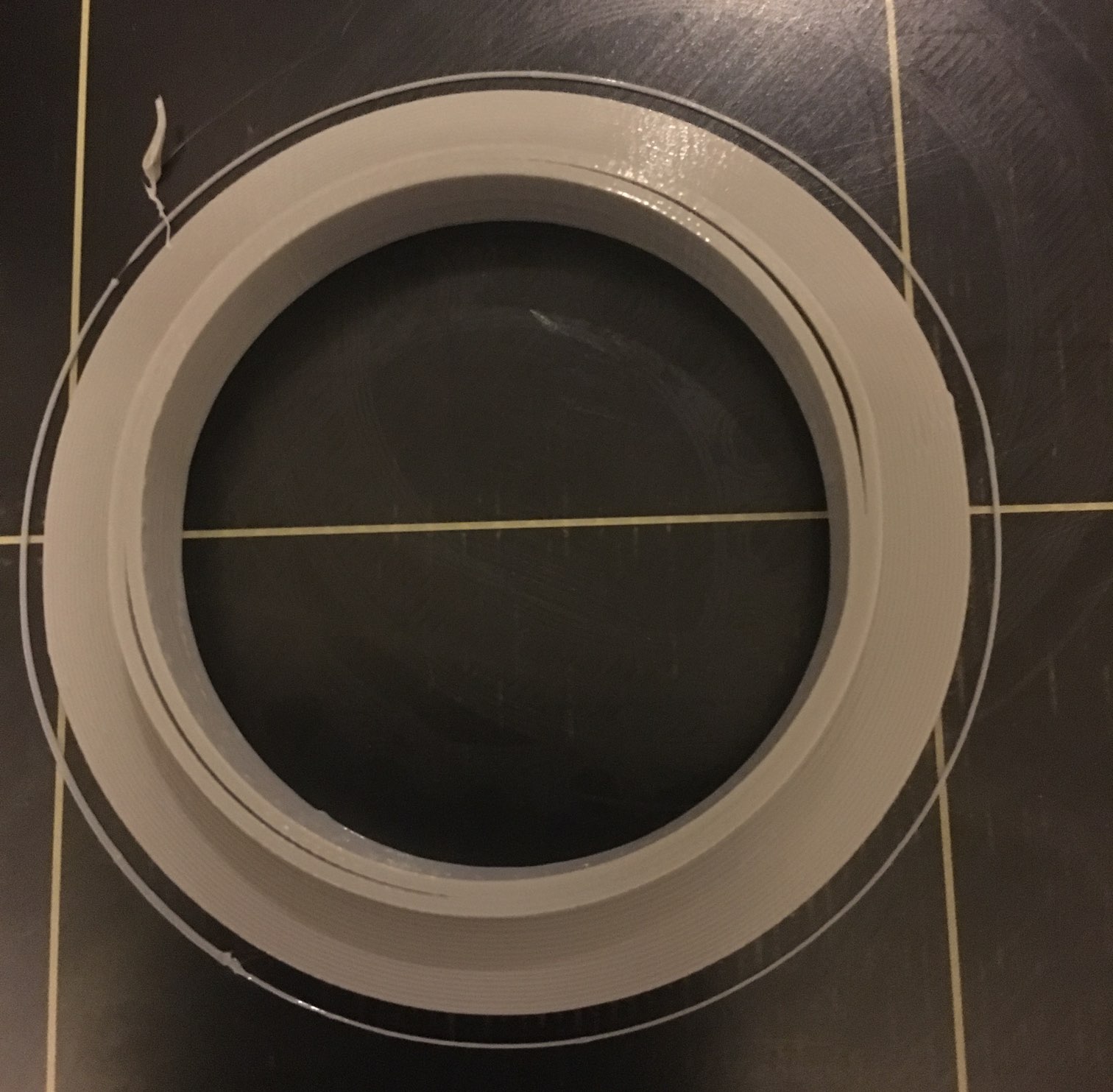

Bottom of the first two attempts. Gap is identical on both and in same orientation:

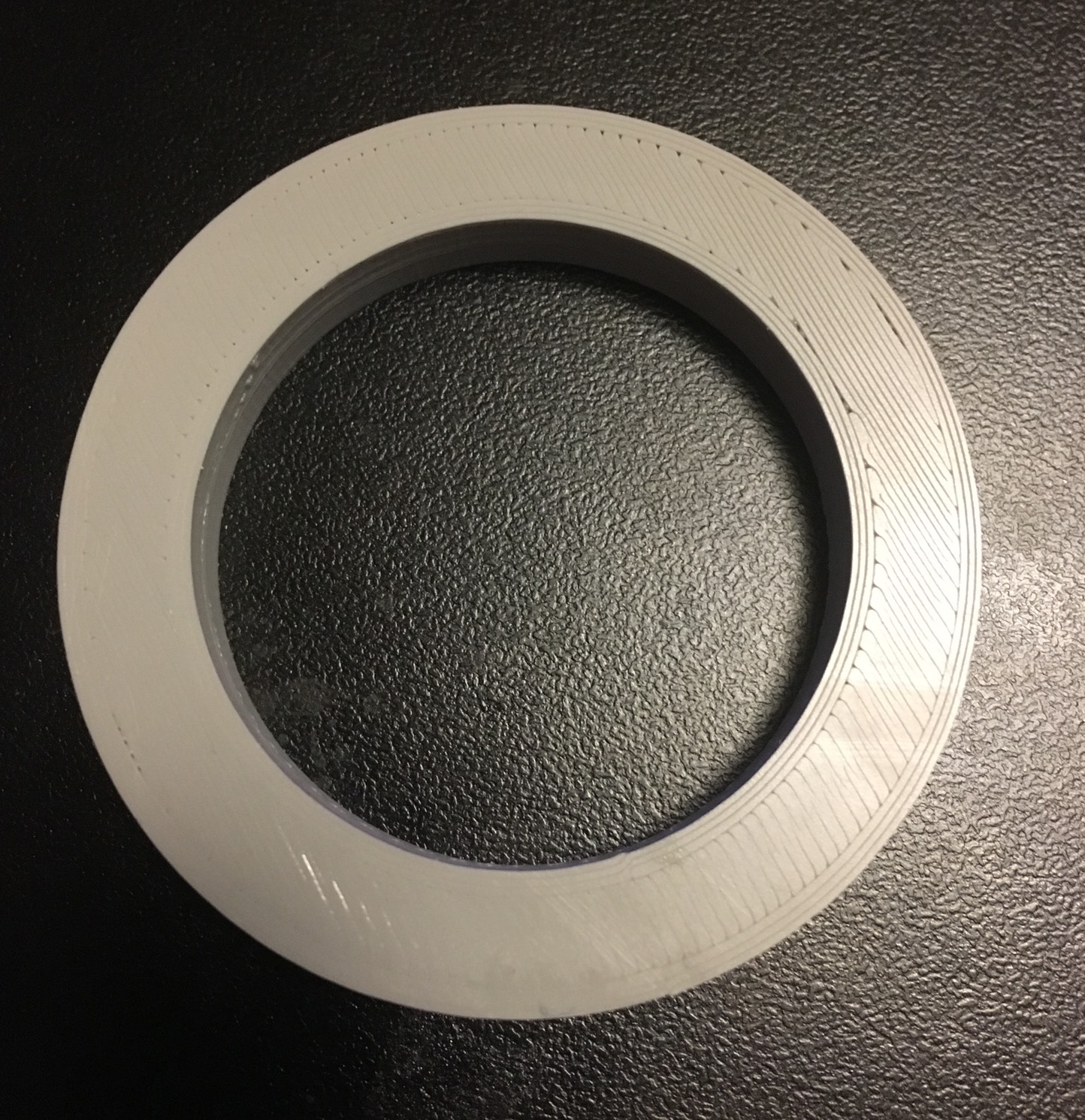

Top of second of first two attempts. Gap is same as the as the first (omitted):

Bottom of third attempt (after loosen idler). Better (but not perfect):

Top of third attempt (after loosen idler). Better (gap is about half, may not be obvious in pic, but in person it is):

Hmmm... can't seem to attach more images... See next post.

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

Without reading too heavy into what went on earlier, my first thought was a small backlash compensation which I think can be done in the software.

I had a similar issue with my printer and all it took was slight adjustment to the Y backlash in my case. Been right as rain ever since.

I have a file on Thingiverse that I use that is similar to what you are using there but makes it easier to determine.

Gaps in 10 o'clock or 4 o'clock position: = adjust Y backlash compensation.

Gaps in 8 o'clock or 2 o'clock position: = adjust X backlash compensation.

http://www.thingiverse.com/thing:1866977

Up to you. I could be wrong here too.

Yeah, its that guy... 3D Nexus

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

Jason

Which slicer are you using?

You could try revolving the model by 90 degrees in the slicer to see if the problems move

Then...

There are settings you can make within most slicers to mostly resolve the bottom layer gaps (Loop/Solid Overlap). I think the top gap could be due to extrusion width setting, with the gap being less than the extrusion width.

{silly example} If I were creating a cylinder with a wall thickness of 2.5mm and used an extrusion width of 0.45mm then there would be a gap of 0.25mm in the centre of the wall. I would want to make the wall thickness a multiple of the extrusion width (in this case 2.7mm) or change the extrusion width to 0.5mm.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

I have a file on Thingiverse that I use that is similar to what you are using there but makes it easier to determine.

Gaps in 10 o'clock or 4 o'clock position: = adjust Y backlash compensation.

Gaps in 8 o'clock or 2 o'clock position: = adjust X backlash compensation.

Thanks. Is that a setting in the slicer? I don't remember seeing it. I use Simplify3D. However I think my issue is solved in terms of it being at an angle (I have fixed that- now it's at least even all around).

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

Jason

Which slicer are you using?

...

{silly example} If I were creating a cylinder with a wall thickness of 2.5mm and used an extrusion width of 0.45mm then there would be a gap of 0.25mm in the centre of the wall. I would want to make the wall thickness a multiple of the extrusion width (in this case 2.7mm) or change the extrusion width to 0.5mm.

Peter

I am using Simplify3D. My last print worked out better after re-calibrating. The gap is still there BUT it is now even all the way around. The bottom layer is loose still as well but it is consistent all the way across. Therefore I think that your comments are correct, I think I just need to play a bit with the settings to get it perfect (or as close to it as possible). I also suspect you are correct about the size of the top being just a fraction to big for the extrude width. I am not sure what it is I did not create the model.

Thanks for your insight.

J.

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

could you try one perimiter. that should persuade the slicer to fill the top with infil, rather than insufficient perimeters.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

I have a file on Thingiverse that I use that is similar to what you are using there but makes it easier to determine.

Gaps in 10 o'clock or 4 o'clock position: = adjust Y backlash compensation.

Gaps in 8 o'clock or 2 o'clock position: = adjust X backlash compensation.

Thanks. Is that a setting in the slicer? I don't remember seeing it. I use Simplify3D. However I think my issue is solved in terms of it being at an angle (I have fixed that- now it's at least even all around).

I use at this stage, Cura and Octoprint. I went to Simplify3D to check for you and basically found a war going on regarding backlash. It was ugly and it led me to believe that the settings arent there in Simplify3D. I could be wrong, so maybe someone who is using it actively can chime in.

My point to argue (not here, there) would be that any setting that leads to producing a quality print should be considered. I have machining background and little with 3D printers, but CNC equipment works in the same "realm" of physics, which I do have that experience with and backlash is a fact of an engineers life on that equipment. All I know is my prints had exactly the same issues (2 different from what I can see) you have, and the layer gaps like you showed went away completely for me once I made an adjustment to backlash and haven't appeared since. The layer gap on that first horizontal spacing is a different setting that I havent had to toy with. I know that it can also be adjusted because in the stock slicer software with my printer definitely uses something different than what Cura and Octoprint has going on because printing the same part in each produces different results yet I have the backlash set with my new adjustments in both and the other issue is still resolved.

When I'm sitting at the workstation and nothing is happening I (out of my own sanity) need to explore every option. I'm still learning too but when something works, it works. I like to know why so I dont have to reinvent the wheel the next time. Just offering some insight because thats what we come here for. 🙂

Yeah, its that guy... 3D Nexus

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

I want to add too, the reason I had to explore was the first time I tried printing a sphere. It came out slightly egg shaped and for what I do, even a slight offset isn't acceptable. I detect visually the same "out of round" thing going on in your photos, so maybe (with nothing to lose) try printing a sphere test object?

All I did was hop in tinkercad and made a 20mm high def sphere, threw a base on it and printed it.

http://www.thingiverse.com/thing:1869141 (half sphere)

http://www.thingiverse.com/thing:1869145 (full sphere)

I didn't have them saved, so I just threw a couple back together.

Yeah, its that guy... 3D Nexus

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

All I did was hop in tinkercad and made a 20mm high def sphere, threw a base on it and printed it.

http://www.thingiverse.com/thing:1869141 (half sphere)

http://www.thingiverse.com/thing:1869145 (full sphere)

I didn't have them saved, so I just threw a couple back together.

Thanks Ancientwolf,

I was actually able to correct the geometry by loosening the x axis idler and recalibration. However I am going to give your prints a shot just to double check everything is correct.

As for this object - I have it now printing well, required some adjustments to my z offset as well as perimeter settings.

Thanks for your help.

J.

Re: Gaps in perimeter and between perimeter and infill at 45 degree angle

{silly example} If I were creating a cylinder with a wall thickness of 2.5mm and used an extrusion width of 0.45mm then there would be a gap of 0.25mm in the centre of the wall. I would want to make the wall thickness a multiple of the extrusion width (in this case 2.7mm) or change the extrusion width to 0.5mm.

Peter

Peter, this proved to be the case.

Mathematically there was .2 - .3mm left over in the thickness.

Seems that I had not a gap at 45 degrees but too much compression at the opposite angle.