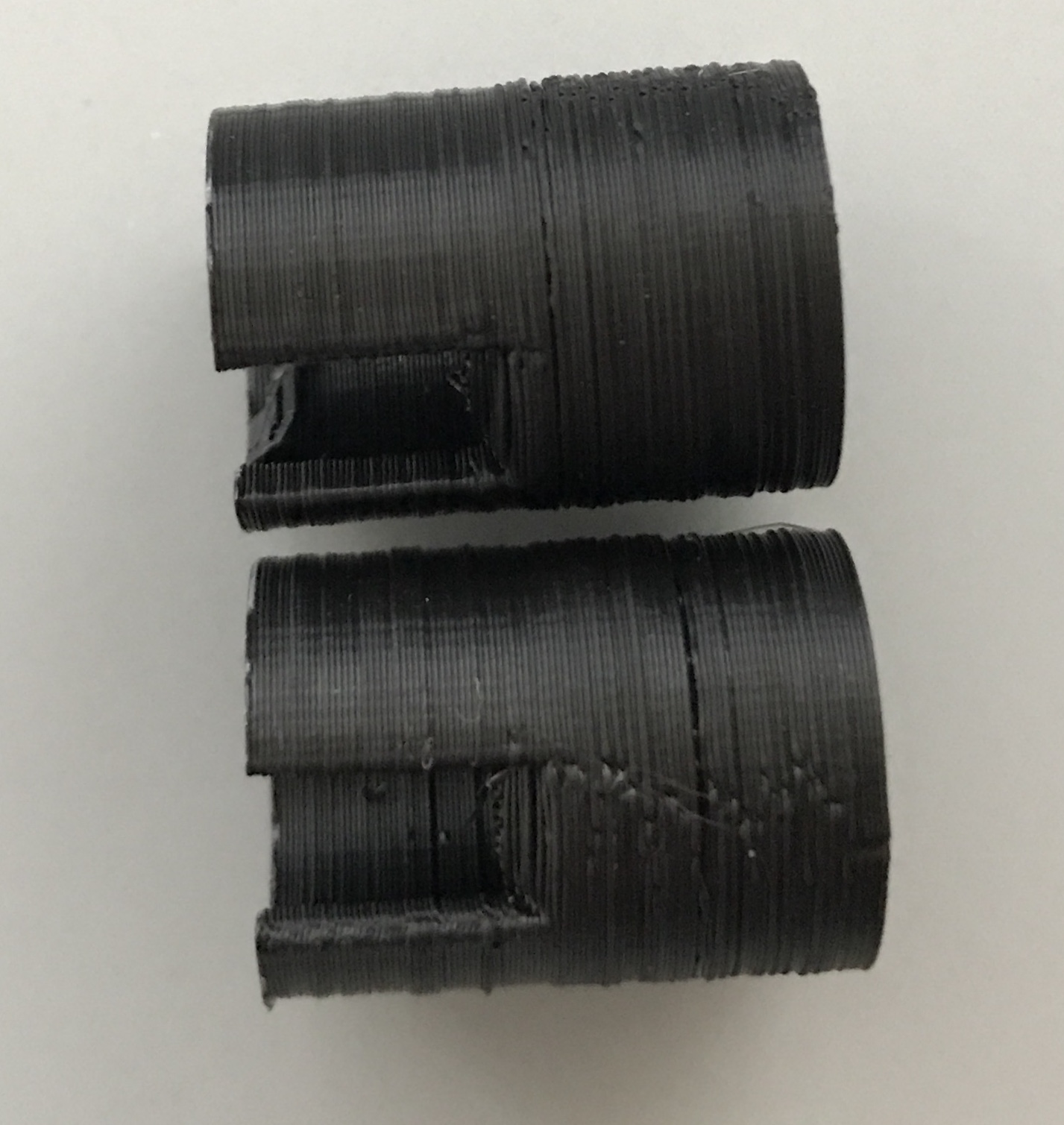

How to improve this print?

I just printed these objects using slic3r for prusa, default prusa PLA settings and using prusa PLA. This is on an mk2s with MMU upgrade, but only using 1 extruder

I think there is room for improvement, but I don't know what exactly to change.

Any advice?

Re: How to improve this print?

That is donkey balls. Whahappon? Too many errors to tackle here, you have bad layer adhesion, complete accuracy breakdown, blobbing and pitting all over the place. For sanity's sake print out a 2cm cube with embossed x,y,z text on appropriate locations. With apples to apples comparo, the forum will be able to tackle the issues more logically.

MK2S kit owner since 8/15/2017

Re: How to improve this print?

Some quick tips:

Blobbing: Check that your nozzle is clean. Check your filament. It might have absorbed some moisture -> dry it

Bad layer adhesion: try some higher print temperatures. +5-20°C might have a positive effect. Also, bad layer adhesion might be a result of moist filament.

----------------------------------------------

PRUSA MK2

- Noctua fan 40mm

- MK2/MK3 hybrid extruder

Re: How to improve this print?

As Stephen suggests, there are way too many problems with the print to be able to diagnose in a single post.

My first thought is to rebuild the printer from scratch, but this time to follow the manual - it's there for a reason (and the reason is not to"to be ignored").

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: How to improve this print?

PJR: The printer was printing perfectly fine before the MMU installation. And I did follow the manual.

I increased the nozzle temp from 205 to 215 and it's a lot better. Still having issues printing supports though. Going to print some calibration objects and report back.

Re: How to improve this print?

That benchy looks poor. Was it pre-sliced?

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: How to improve this print?

That's the file that's included in the prusa examples. Threw the gcode file directly at the printer.

Not really happy with what's coming out atm. Supports are also very flimsy and unstable (no wonder if you see the above images). Going to start from square 1 and do the basic tests. Too bad as with the single extruder it worked quite well. Seems I have to start all over again.

Re: How to improve this print?

Also, a photo of your printer so we can see if there is an environmental issue. I had part of my enclosure pinching a PTFE tube on a remote filament dispenser someone else spotted. I think your problems are more fundamental though, i.e. misaligned belt, unparallel or heavily pitted rods, lost balls (I don't judge). More remote cause could be violently oscillating fan, frayed or high EM interfered motor wires, placed on top of washing machine or trophy truck at full speed...maybe, hopefully? I don't know.

MK2S kit owner since 8/15/2017

Re: How to improve this print?

Well. Seems I won't be testing anytime soon now. PINDA probe started acting up. Can't print anymore. It still reacts to metal but when checking the endstops in the lcd Z always stays on 1.

To be continued ...

Re: How to improve this print?

I once had issues with PINDA since installing my fine tune PINDA plunger. In my case, many mods had caused frame alignment to go off. PINDA doesn't work if bed is too far off perpendicular. My corrections were 2° forward lean and 1° frame off in roll. Some brute force and a couple aluminum shims later and all my sensor points came back, there was nothing wrong with bed or PINDA it turned out. Hopefully, you're in the same boat.

MK2S kit owner since 8/15/2017

Re: How to improve this print?

that sounds like a cable fault.

sounds like +ve and gnd are ok, but signal wire may be high resistance or open circuit

this can happen with poor cable management, or lots of use...

it's likely that the problem is just behind the extruder mount where the cables start to flex in use. you should be able to replace one wire and restore service

regards joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: How to improve this print?

just unmounted some cables, disconnected and reconnected the PINDA, also saw that the temperature sensor of my heated bed had come loose from the bed (it wasn't my day it seems), so I fixed everything, reconnected PINDA, moved some stuff around and ran all the calibrations again. All seems ok now (orthogonality ok etc etc), so it seems I can start my first print test now.

Re: How to improve this print?

ok here we go. Let me know what you think please, as I am still an amateur 🙂

Re: How to improve this print?

Printed with Slic3r Prusa edition

0.2mm height

20% infill

no supports

all layers at 215 degrees

build plate at 55 degrees

perimeters printed at 40 mm/s

infill at 60mm/s

Re: How to improve this print?

You can see that the small "stick" in the cilinder on the top isn't centered. It fell over during printing.

Re: How to improve this print?

This is the object btw:

http://www.thingiverse.com/thing:2166102

I just started the print again, but with a vibration absorbing surface underneath the printer.

Re: How to improve this print?

Looks like you're getting directional shifts within half mm range which points to something loose. Since overall dimensional accuracy looks good steppers aren't slipping or jumping, so not them. Your Z is pretty great which has no belt or grub screws to miss. If your frame was loose, you would have crushed layers which you don't have, so not that.

My theory are these.

1. Belt is too slack. Tighten to "base E" as per Tom Sanladerer, or as close as you can, they should be tight enough to have noticeable spring.

2. Drive gears are loose (grub screws loose) or grinding on belt (not perfectly aligned with belt path).

3. Rods are not tight and right, did you remember to tighten gantry side screws for x-axis? Is there any play in Z-rods? Does your bed shift at all when rotated about it's center (aka yaw slack), up and down is not as important.

Yup, that is what I can gather from my experiences.

MK2S kit owner since 8/15/2017

Re: How to improve this print?

Um, you shouldn't really put dampers on the base of the printer that isn't firm like rubber or felt. It will actually increase resonances to travel in skew possibly whacking your printer out of true. Why Prusa thought a parallelogram held square with friction against an inherently flexible plastic with questionable dimensional accuracy is beyond me, but anyway you want the printer on a perfectly flat and strong surface such as glass, granite, concrete, wood, metal, anything flat that doesn't flex. If you then choose to dampen the flat thing, go for it. Most on these forums use stock felt feet on a paving stone sitting on a damper of some kind. Some put lateral supports under the frame to match pressure with feet but I don't, and my printer's Benchie looks like it came out of an injection mold...well before I went and screwed it up with stepper dampers. Printer vibration harmonics (flutter for aero or mechanical resonance for mechanicals) is the least of your printers problems, IMHO. But, maybe with the weight of the MMU, lateral supports may not be such a bad idea as I don't have MMU and those bunions look heavy. Similarly I have relocated my filaments on top of my enclosure due to low frequency resonance concerns with the inadequate gusseting provided by PSU mound design.

MK2S kit owner since 8/15/2017

Re: How to improve this print?

Um, you shouldn't really put dampers on the base of the printer that isn't firm like rubber or felt. It will actually increase resonances to travel in skew possibly whacking your printer out of true. Why Prusa thought a parallelogram held square with friction against an inherently flexible plastic with questionable dimensional accuracy is beyond me,

Well, I have been using printed dampers on these printers for 3 years now. They work very well and I have never had any issues. Occasionally they start to collapse and need to be re-printed but otherwise they work.

I think PR thought it was a good idea because it is... 😉

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…