Prusa Orange PETG gcode or profile for Orig Prusa Parts

Since this past Friday I've been trying to dial in a profile for Prusa Orange PETG so that I can print backup parts. I'm about 1/4 way though a spool and I'm still not dialed in to what shipped with the MK3. The stock slic3r PE Prusa PETG profile is such a disaster that I stuck with a Simplify3D profile and tweaked from there. (The first layer on Slic3r pulls and blobs so bad that I got tired of stopping the print, cleaning the nozzle head and surrounding area, tweaking and retrying. Yes live Z is calibrated to the PETG.) I've downloaded about 1/2 a dozen S3D MK3 PETG profiles and tried to take the best parts of each and tweak them into something usable.

Since the filament is used on a mass basis by Prusa I'm assuming they've got some really good gcode and/or profiles for this filament. Would it be possible to share the g-code to those parts or a profile that will get us at least 90% there? It's been frustrating as heck as no profile has really given me particularly good results. I can get great results from PLA so I know it's not the printer.

Mano

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

The replies from prusa people boil down to "We print a whole plate of parts, so our gcodes won't be of any use". I am curious about layerheight and speeds, though.

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

I have just taken the stl files and sliced them with the Prusa settings.

Just like Jakub wrote in this thread.

https://shop.prusa3d.com/forum/original-prusa-i3-mk3-f30/new-printed-parts-version-r2-b6-t14551.html

And nearly every part looks like the stock one´s, except the nice surface.

Mine is just "glass like" flat.

Wer freundlich fragt bekommt auch eine freundliche Antwort.

nec aspera terrent

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

I spent 3 days last week trying to get a successfull print with the Prusa Orange PETG. I finally had success with the standard Slic3r PETG profile, just tweeked the first layer temp to 240 and reduced max speed to 50 mm/s. The Live Z first layer height was the most critical for me, small tweaks made a big difference. I finally ended up printing the Batman logo and kept tweaking live Z until the first layer was perfect, gave me better results than the first layer calibration. After tweaking was successful with my first PETG print, 41 hours of printing later.

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

I know Prusa recommended using Slic3r PE or Prusa Control to slice the upgraded parts but the print speeds were way too high. I used Slic3r PE and adjusted the speeds settings very low. I'm pretty sure the fastest speeds I had were perimeter and infill at 35mm/s. The extruder movements were originally so fast that infill was being torn away before it could cool to the part.

I posted my speed settings on another thread, I'll try to find them.

Edit: found my post:

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

The replies from prusa people boil down to "We print a whole plate of parts, so our gcodes won't be of any use". I am curious about layerheight and speeds, though.

Yea, I wouldn't mind that gcode. I'd like to just print all the orange on one run and all the back on another. It's for backup parts so that would work fine for me!

I have just taken the stl files and sliced them with the Prusa settings.

Just like Jakub wrote in this thread.

https://shop.prusa3d.com/forum/original-prusa-i3-mk3-f30/new-printed-parts-version-r2-b6-t14551.html

And nearly every part looks like the stock one´s, except the nice surface.

Mine is just "glass like" flat.

Not mine. I messed with speed settings, height and no matter what I did I couldn't get a decent first layer with the stock slic3r profiles.

I spent 3 days last week trying to get a successfull print with the Prusa Orange PETG. I finally had success with the standard Slic3r PETG profile, just tweeked the first layer temp to 240 and reduced max speed to 50 mm/s. The Live Z first layer height was the most critical for me, small tweaks made a big difference. I finally ended up printing the Batman logo and kept tweaking live Z until the first layer was perfect, gave me better results than the first layer calibration. After tweaking was successful with my first PETG print, 41 hours of printing later.

I've got a solid z layer height. It's printing well with S3D now. Just not as well as the stock prusa parts.

You're finished product looks amazing btw. Mine is nowhere near that clean.

I'll give it another shot when I get home. I tried lowering speed and increasing temps to 240 but maybe I missed something.

The extruder movements were originally so fast that infill was being torn away before it could cool to the part.

I posted my speed settings on another thread, I'll try to find them.

Edit: found my post:

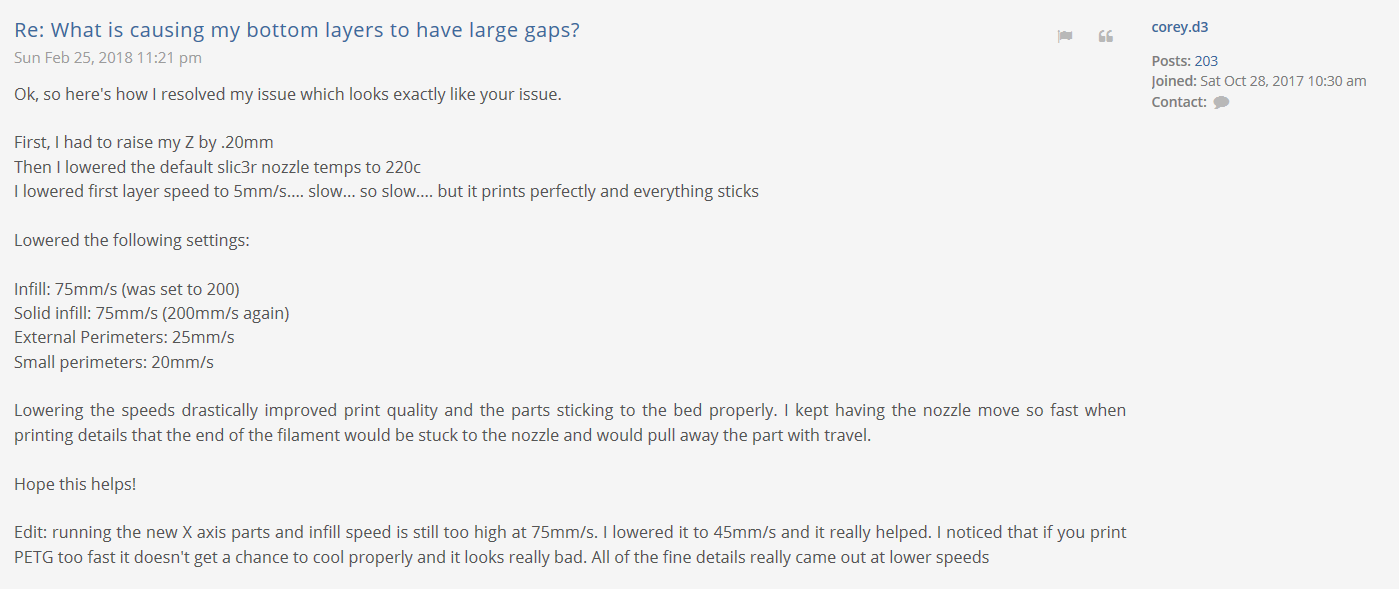

2018-03-28 12_33_03-What is causing my bottom layers to have large gaps_ - Page 2 - Prusa Research -.png

That's what's happening to me. The first layer is getting pulled all over the bed. It looks like it's getting stuck to the nozzle and then getting ripped off the bed.

I tried slowing down to 30mm/sec first layer but that had no effect. Raised my live Z by .02 for Simplify 3D and that gave me a better first layer. It didn't seem to make a bit of difference to Slic3r though.

Thanks for the suggestions. I'll give it a shot again and see where it goes.

Mano

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

Thanks for the suggestions. I'll give it a shot again and see where it goes.

Mano

Silly question, are you also using a sock?

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

Thanks for the suggestions. I'll give it a shot again and see where it goes.

Mano

Silly question, are you also using a sock?

No. I did order one a couple days back though. Getting tired of cleaning the nozzle. You think it will help?

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

No. I did order one a couple days back though. Getting tired of cleaning the nozzle. You think it will help?

Make sure you buy the V2 sock that has the whole nozzle exposed, not the tip. I was asking because my first layer adhesion issues were also caused by the v1 sock, the one with the very tip just sticking out. The sock started to sag just a little bit and was making contact with the extruded layers.

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

No. I did order one a couple days back though. Getting tired of cleaning the nozzle. You think it will help?

Make sure you buy the V2 sock that has the whole nozzle exposed, not the tip. I was asking because my first layer adhesion issues were also caused by the v1 sock, the one with the very tip just sticking out. The sock started to sag just a little bit and was making contact with the extruded layers.

Crap I ordered the V1 version. Fits pretty snug & I don't see any sagging. Thanks for the heads up on that. I'll def keep an eye on it.

I re-calibrated the PID and tossed the values into my g-code. I didn't have variance in temps like others I've seen posted. I live in FL so we our temps never get really cold to where it affects the printer. I bought it mainly to keep gunk off the nozzle. Only got through 3/4 of a print before my PSU blew though. CS shipped one today. That's less than 24 hr turnaround time! Not happy about the PSU but ecstatic about response.

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

I have printed all the plastic parts as spares using the std PRUSA PETG settings and max speed with the PRUSA PETG Orange and I get better parts than those supplied by Prusa in my kit. What have I done? Both x and Y idlers changed to teethed idlers 20 teeth dual bearings and the x and y bands changed to PU steel belted ones. All bearings lubed with lithium grease direct during assembly including extruder idlers and bondtech gears. My belt tension is less than what Prusa recomends intentionaly as the PU steel belted "chains" are very rigid in relation to there movements ie they do not flex at all. Running allmost everything att max speed also printed ABS high visabilty fan shroud without problems and better layers than the original parts.

My skew after assembly is 0.02 and I am now using a Buildtak surface as the original broke after printing all the spare parts for my MK3. I see no real difference with the BuildTak other than adjusing the live Z due to its thickness. These are my personal reflections and experiences. Use them if you want or cast them of if you want.

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

I have printed all the plastic parts as spares using the std PRUSA PETG settings and max speed with the PRUSA PETG Orange and I get better parts than those supplied by Prusa in my kit. What have I done? Both x and Y idlers changed to teethed idlers 20 teeth dual bearings and the x and y bands changed to PU steel belted ones. All bearings lubed with lithium grease direct during assembly including extruder idlers and bondtech gears. My belt tension is less than what Prusa recommends intentionally as the PU steel belted "chains" are very rigid in relation to there movements ie they do not flex at all. Running almost everything at max speed also printed ABS high visibility fan shroud without problems and better layers than the original parts.

My skew after assembly is 0.02 and I am now using a Buildtak surface as the original broke after printing all the spare parts for my MK3. I see no real difference with the BuildTak other than adjusting the live Z due to its thickness. These are my personal reflections and experiences. Use them if you want or cast them of if you want.

Thanks for the info. It's abit advanced for me. I didn't build the machine and unless there is a step by step outlining the steps I won't be changing the parts till they break. That said I will look into what you did and keep it mind when I do need to disassemble the machine to replace a part or other maintenance on the idlers and belts. If you don't mind please post links of the parts you bought. I'm compiling a list of things I will change when I need to.

The stock profile didn't work for me at all. No amount of changing speeds, first layer height or temp worked. The first layer just comes as jumbled lump of plastic stuck to the extruder. I feel like I am tweaking every setting under the sun to get a mediocre result.

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

Crap I ordered the V1 version. Fits pretty snug & I don't see any sagging. Thanks for the heads up on that. I'll def keep an eye on it.

My v1 sock sat snug for a while and then it started to sag ever so slightly. The silicone will get tired from the heat after several hours of printing. Plus rapid movements don't help the cause either.

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

I found these on the Prusa site, https://bit.ly/2uA9SZT

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

I found these on the Prusa site, https://bit.ly/2uA9SZT

Looks like it's all of the parts or a full bed of parts. 1 gcode is an 18h print and the other is a 15h print.

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

I found these on the Prusa site, https://bit.ly/2uA9SZT

Looks like it's all of the parts or a full bed of parts. 1 gcode is an 18h print and the other is a 15h print.

Yeah, but being it's Prusa's official GCode you can apply the GCode settings to your slicer for the parts you want to print. I was a bit surprised by the 20% fill density, I assumed it would be higher... Found here... https://www.prusa3d.com/downloads/others/

Re: Prusa Orange PETG gcode or profile for Orig Prusa Parts

I found these on the Prusa site, https://bit.ly/2uA9SZT

Thank you!!! I searched but came up empty.